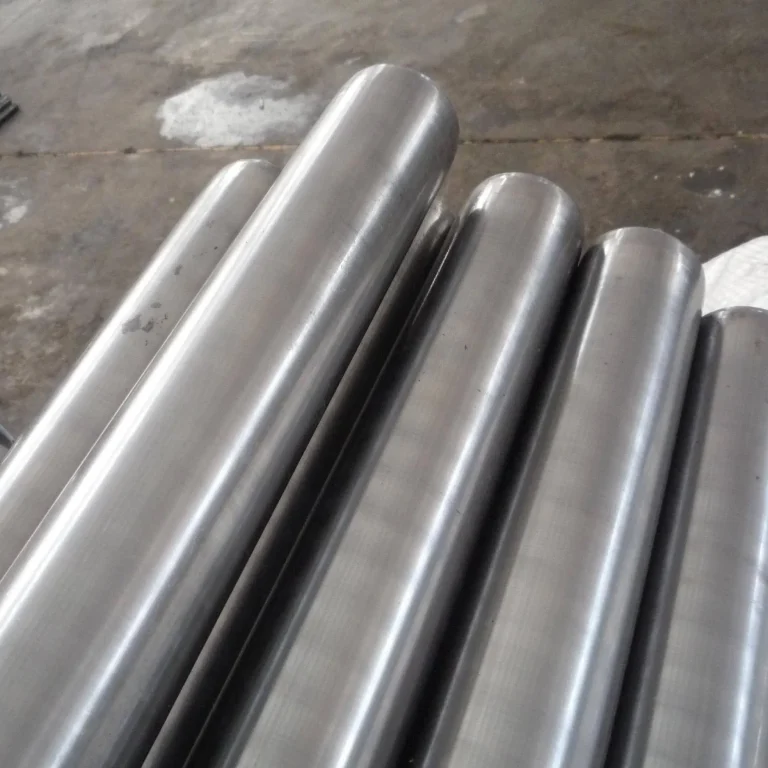

Sensitization of stainless steel is a critical issue. It’s a metallurgical change. It can severely compromise a material’s integrity. It’s also known as “weld decay.” This happens to stainless steel pipes and stainless steel pipe fittings. Understanding it is vital. It prevents unexpected failures.

Sensitization of stainless steel : A Hidden Threat

Stainless steel undergoes sensitization when heated.This phenomenon typically occurs between 450℃ and 850℃(840℉ to 1560℉).High temperatures promote the formation of chromium carbides,which precipitate along grain boundaries,depleting chromium in the adjacent regions.These chromium-depleted zones become susceptible to corrosion,allowing corrosion to occur even when the rest of the material remains intact.

What We Do

- Pipes >

- Fittings >

- Flanges >

- More >

How Sensitization Affects Your Piping

Sensitized areas lack enough chromium. They lose their passive layer. This makes them prone to intergranular corrosion. The attack happens along the grain boundaries. This weakens the material.

The corroded grain boundaries become weak points. They can lead to cracks and fractures. This is especially true under stress. This compromises the pipe’s integrity.

Sensitization is hard to see. The surface looks normal. Failures can happen suddenly. This results in leaks. It causes dangerous system downtime.

The most common cause is welding. The heat-affected zone (HAZ) becomes sensitized. It is the weakest point of the entire system.

Sensitization Effects on Stainless Steel Pipe and Fittings

| Property | Before Sensitization | After Sensitization |

|---|---|---|

| Corrosion Resistance | Excellent | Poor (in sensitized zone) |

| Microstructure | Uniform, clean | Carbides at grain boundaries |

| Mechanical Integrity | High | Compromised |

How to Prevent Sensitization of Stainless Steel

How to Prevent Sensitization of Stainless Steel

The easiest way to prevent sensitization is to Choose The Right Material.

| Method | Explanation | Example Grades |

|---|---|---|

| Low-Carbon Grades | Reduces carbon available for carbides | 304L, 316L |

| Stabilized Grades | Contains titanium or niobium | 321, 347, 316Ti |

- The low carbon content of 304L suppresses sensitization during welding, making it an ideal choice for welded components.

- 316Ti stabilizes the alloy composition with titanium, effectively preventing weld degradation, making it the superior choice for high-temperature environments.

Preventing Sensitization : Manufacturing and Treatment

- Solution Annealing: This is a heat treatment. It heats the steel to a high temperature. It then cools it quickly. This dissolves the chromium carbides. This restores the passive layer.

- Controlled Welding: Use low heat input welding methods. This reduces the time the material spends in the sensitization temperature range.

- Post-Weld Cleaning: Clean the weld area thoroughly. Remove all heat tint and oxides. Then, passivate the surface. This restores the protective layer.

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/