Our Product

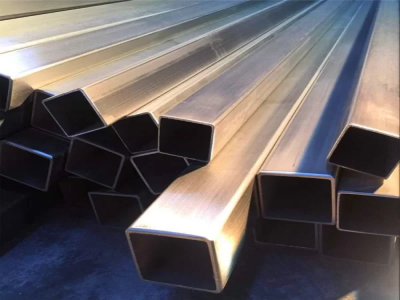

Stainless Steel Tubing

More than 20 years to manufacture and supply stainless steel tubing comply with ASTM A213/A269, ASTM A312, ASTM A789, EN 10216-5, DIN 17456, 17458 etc, dimension from 6mm to 204mm.

- Stainless Steel 304/304L, 316/316L, 321, 316Ti, 317L, 347H, 904L, 254 SMO

- Duplex 2205, Super Duplex 2507

- Alloy Monel 400, Inconel 600, 625, Incoloy 800H, 825, Hastelloy C276, C22