Stainless Steel VS Carbon Steel is a fundamental choice for piping system,It affects performance,cost and lifespan.Both materials are widely used.They serve different purposes. Understanding their unique properties is vital.Professional stainless steel pipe and fittings supplier helps you decide.

Stainless Steel VS Carbon Steel : Core Difference

The main difference lies in chromium content,stainless steel contains a minimum of 10.5% chromium. This element forms a thin, passive layer. This layer prevents rust and corrosion. Carbon steel lacks this chromium. It is primarily an alloy of iron and carbon,so it rusts easily when exposed to moisture. This key difference dictates their applications.

Stainless Steel VS Carbon Steel : Pros and Cons

Stainless steel boasts superior corrosion resistance. The chromium oxide layer protects it. Carbon steel rusts quickly without a protective coating. This makes stainless steel ideal for wet or corrosive environments.

Carbon steel is generally more affordable. It offers good strength. Stainless steel is more expensive. This is due to its chromium and nickel content. For many structural applications, carbon steel is a cost-effective choice.

Stainless steel requires less maintenance. Its corrosion resistance means a longer lifespan. Carbon steel needs protective coatings. These coatings require reapplication. This adds to long-term maintenance costs.

Both are weldable. Carbon steel is generally easier to weld. Stainless steel requires specific techniques. This is due to its alloying elements. This can affect fabrication costs and speed.

Stainless Steel VS Carbon Steel : Key Properties

| Feature | Stainless Steel | Carbon Steel |

|---|---|---|

| Corrosion Resistance | Excellent | Poor (without coating) |

| Cost | High | Low |

| Strength | Good to Very High | Very High |

| Weldability | Good (with special care) | Excellent |

| Appearance | Shiny, clean, aesthetic | Dull, requires coating |

What We Do

- Pipes >

- Fittings >

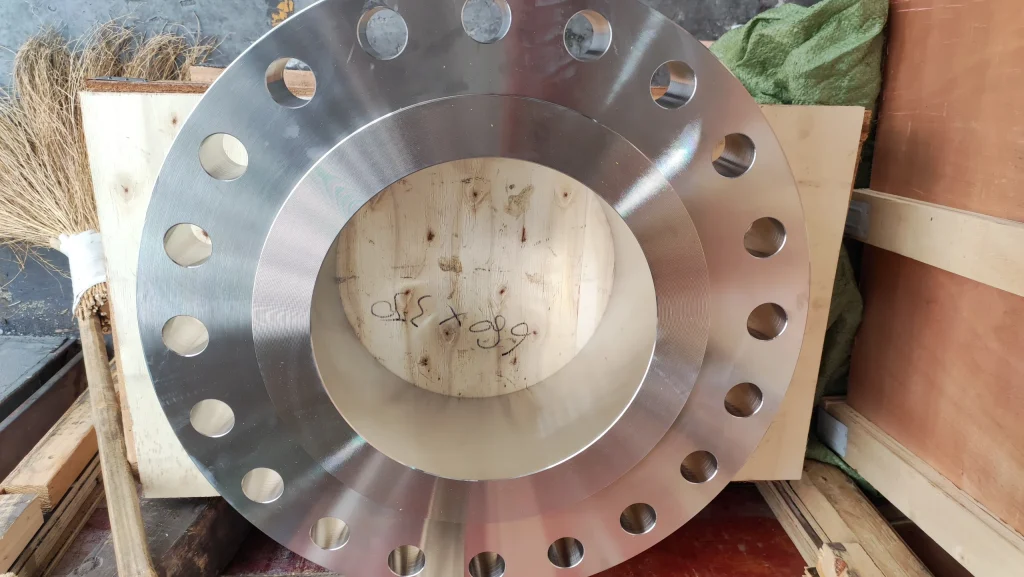

- Flanges >

- More >

Stainless Steel VS Carbon Steel : Applications

| Application Type | Stainless Steel Preferred | Carbon Steel Preferred |

|---|---|---|

| Corrosive Environments | Chemical processing, food, marine | Not recommended (unless coated) |

| General Utilities | High-purity water, medical gas | Water, oil, gas (non-corrosive) |

| Structural | Architectural, decorative, outdoor | Buildings, heavy machinery, frames |

| High Temperatures | Furnaces, heat exchangers | Power plants, steam lines |

| Cost-Sensitive Projects | When corrosion is a factor | When cost is the primary driver |

Common Grades of Stainless Steel

| Grade | Key Feature | Primary Advantage | Typical Use Case |

|---|---|---|---|

| 304/304L | Standard alloy | Cost-effective, good rust resist | General utilities, food |

| 316/316L | Molybdenum added | Chloride resistance, no pitting | Marine, chemical, pharma |

| 310S | High Cr/Ni | Excellent high-temp resist | Furnace parts, exchangers |

| 2205 (Duplex) | Ferritic-austenitic | High strength, SCC resist | Offshore, sour service |

| 321 | Titanium stabilized | Resists weld decay | High-temp exhaust |

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/