1.4410 (UNS S32750) is the European designation for an advanced super duplex stainless steel exhibiting exceptional resistance to stress corrosion cracking and pitting corrosion.

1.4410 and Its Unique Structure

It is a super duplex stainless steel.It consists of a precisely balanced mixture of austenitic and ferritic phases,typically maintaining a 50:50 microstructural ratio.This structure endows the alloy with a unique combination of properties,offering both high strength and high corrosion resistance.

- The ferrite phase provides excellent resistance to SCC.

- The austenite phase contributes to toughness and ductility.It also helps to maintain good weldability.

What We Do

- Plate

- Sheet

- Forgings

- Round Bar

- Flange

- Pipes

- Fittings

- Customized

Contact Us For More Information

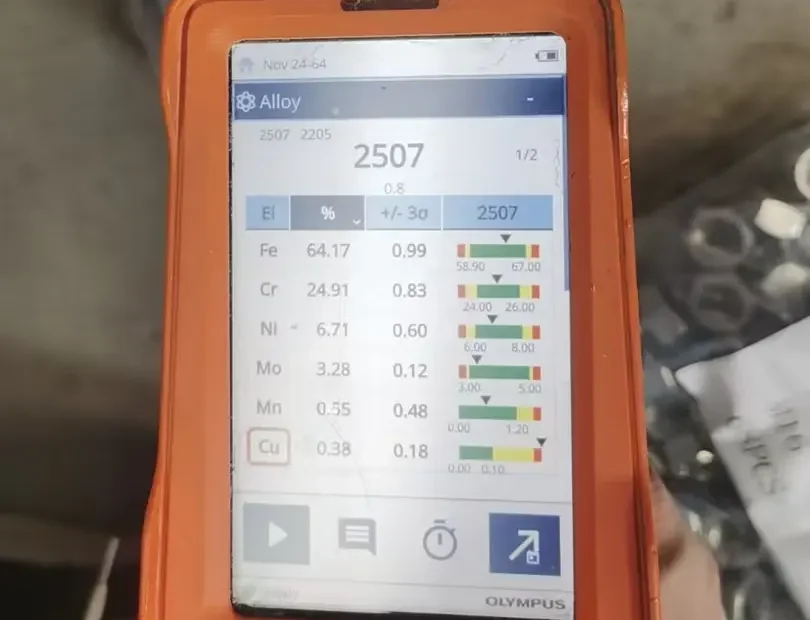

Chemical Composition of 1.4410

The exceptional properties of 1.4410 material are directly attributable to its unique chemical composition.This alloy contains high levels of chromium,molybdenum and nitrogen,which collectively determine its pitting resistance equivalent number (PREN).

The PREN value of 1.4410 typically exceeds 40. Such a high PREN value serves as authoritative evidence of its exceptional resistance to localized corrosion,immediately distinguishing it from standard duplex stainless steels—as detailed in comparative discussions between materials like 1.4410 and 1.4462.

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|---|

| Content (wt%) | ≤ 0.030 | ≤ 0.80 | ≤ 1.20 | ≤ 0.035 | ≤ 0.015 | 24.0 – 26.0 | 6.0 – 8.0 | 3.0 – 4.5 | 0.24 – 0.35 |

Mechanical Properties of 1.4410

The high alloy content endows 1.4410 with exceptional mechanical properties.Its yield strength is approximately twice that of common austenitic stainless steel grades like 316L.Consequently,engineers can design systems with thinner walls, thereby reducing overall material weight and cost.

| Property | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Hardness | Density |

|---|---|---|---|---|---|

| Value (Typical) | ≥ 750 MPa | ≥ 550 MPa | ≥ 25 % | ≤ 290 HBW | 7.8 g/cm3 |

Fabrication and Welding Considerations

Working with 1.4410 requires specific expertise.Improper welding or heat treatment can lead to thermal degradation, compromising the material’s properties.

- Heat Input Control:

Welders must strictly control heat input.Excessive heat causes the formation of harmful sigma phase.This brittle phase reduces the material’s toughness and corrosion resistance. - Filler Material:

Welding consumables must contain excess nickel and nitrogen.This ensures the weld metal maintains the correct 50:50 phase equilibrium. - Post-Weld Treatment:

Solution annealing should be performed when conditions permit.This heat treatment restores the optimal phase equilibrium and reestablishes full corrosion resistance.

Applications

- Oil and Gas Industry:Subsea pipelines,risers and process piping.

- Chemical Sector:Heat exchangers and pressure vessels.

- Shipbuilding:Propeller shafts and pump housings.

- Desalination Plants:High-pressure piping systems.

1.4410 VS. 1.4462

The main difference between 1.4410 and the widely used duplex grade 1.4462 (UNS S31803/S32205) lies in the concentration of Mo and N.This chemical difference translates directly to performance,justifying the increased cost of 1.4410.

| Feature | 1.4410 | 1.4462 |

|---|---|---|

| UNS Designation | S32750 | S31803 / S32205 |

| Typical PREN | > 40 | 32 – 35 |

| Pitting Resistance | Excellent (Suitable for ~ 60℃ Chlorides) | Very Good (Suitable for ~ 30℃ Chlorides) |

| Yield Strength | ≥ 550 MPa | ≥ 450 MPa |

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/