253 MA stainless steel is a nickel-saving heat-resistant steel with high creep strength and oxidation resistance up to 1150°C(2102℉).It combines excellent corrosion resistance with favorable machinability.Suitable for stainless steel pipes and fittings in chemical,petroleum,and high-temperature environments.

253 MA Standards

| Alloy Name | Material No. | EN Designation | UNS | China GB |

|---|---|---|---|---|

| 253MA | 1.4835 | X9CrNiSiNCe21-11-2 | S30815 | 1Cr25Ni20Si2 |

What We Do

- Plate

- Sheet

- Forgings

- Round Bar

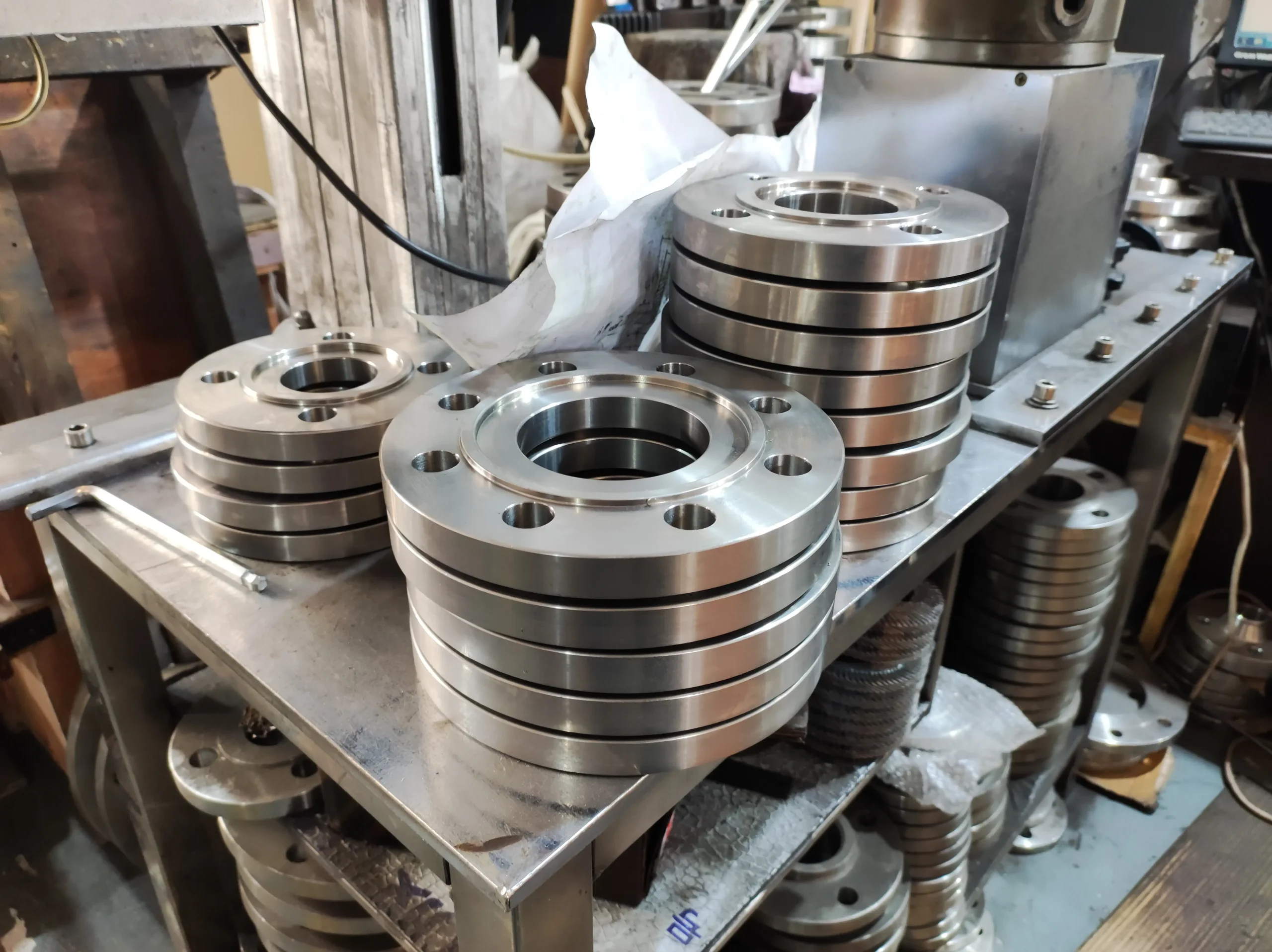

- Flange

- Pipes

- Fittings

- Customized

Contact Us For More Information

Key Characteristics of 253 MA

It exhibits high strength at 900°C(1652℉) and possesses excellent long-term high-temperature performance (creep resistance and endurance).

In air,it can be used up to 1150°C(2102℉) under non-pressure conditions, with a scale formation temperature as high as 1150°C and exceptional oxidation resistance.

At various temperatures,its short-term tensile strength exceeds that of conventional stainless steels (such as 304 and 310S) by over 20%.It exhibits high yield strength and tensile strength at elevated temperatures,enabling normal operation in environments up to 1050°C(1922℉).This makes it suitable for diverse heat treatment processes and high-temperature gas applications.

Containing high proportions of elements such as chromium (Cr) and nickel (Ni),these elements provide excellent resistance to general corrosion and pitting corrosion,particularly in chloride-containing environments.It exhibits good resistance to a wide range of chemical media,including acids and alkalis,making it especially suitable for petroleum,chemical,and marine environments.

Possesses excellent formability,weldability,and sufficient machinability.During processing and forming,it facilitates fabrication into products of various shapes and dimensions,and also enables the manufacture of complex shapes and structures.

Due to its alloy composition,this material exhibits good resistance to stress corrosion cracking and is suitable for applications involving stress in corrosive environments.

Chemical Composition

| Element | C | Si | Mn | P | S | Cr | Ni | N | Ce |

|---|---|---|---|---|---|---|---|---|---|

| Content (wt%) | 0.05 – 0.12 | 1.40 – 2.50 | ≤ 1.00 | ≤ 0.045 | ≤ 0.015 | 20.00 – 22.00 | 10.00 – 12.00 | 0.12 – 0.20 | 0.03 – 0.08 |

Mechanical & Physical Properties

| Property | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Hardness | Density |

|---|---|---|---|---|---|

| Value (Typical) | ≥ 650 – 850 MPa(95 – 123 ksi) | ≥ 310 MPa(45 ksi) | ≥ 40 | ≤ 210 | 7.80g/cm³ |

- Coefficient of Thermal Expansion:

Average of 13.7×10⁻⁶/K between 20°C and high temperatures. - Thermal Conductivity:

Approximately 15 W/m·K (at 20°C). - Electrical Resistivity:

0.85 Ω·mm²/m.

253 MA Applications

| Application Field | Component Type | Component Detail | Size Range | Purpose |

|---|---|---|---|---|

| Metallurgical | Pipe | Recuperator | ≈ 1/2″ – 24″ | Heat Recovery |

| Blast Furnace | Coal Injection | |||

| Heat Treatment | Radiant Tube | Furnace Element | ||

| Thermocouple | Protection Tube | |||

| Fitting | Corrugated box | – | High Temperature | |

| Petrochemical | Pipe | Styrene Reactor | ≈ 1/2″ – 24″ | Process Tube |

| EDC Cracking | Thermal Process | |||

| Convection Tube | Ethylene Cracking | |||

| Power Industry | Boiler Nozzle | Combustion Part | ||

| Refinery/Chemical | Fitting | Heat Exchanger | – | Component Part |

| Expansion Bellow↓ | Thermal Stress | |||

| Refining Industry | Buttweld Elbow | Fluid Redirection | ||

| Buttweld Tee | Branch Connection | |||

| General Furnace | Reducer | Change Diameter | ||

| Sintering/Cement | Cyclone Separator | High Temp Dust |

253 MA stainless steel pipes have a wide nominal size range.

Common seamless pipe sizes range from approximately 1/2“ to 8” NB, while welded pipe sizes range from approximately 6“ to 24” NB (NB = Nominal Bore).

The table uniformly uses ≈ 1/2“ to 24” to indicate the approximate size range of the pipes.

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/