Stainless steel pipes benefits are numerous and crucial for industrial stability.This material provides an unmatched combination of strength and corrosion defense.Choosing stainless steel guarantees reliability for your fluid handling systems.It ensures the longevity of your pipe fittings as well.

What Makes Stainless Steel the Right Choice?

Stainless steel is an iron-based alloy containing no less than 10.5% chromium.This chromium reacts instantly with oxygen to form a thin,stable protective layer of chromium oxide on the surface.This protective film is the key to its properties—it can self-repair when the surface is scratched or damaged.It is precisely this self-healing mechanism that endows stainless steel with its exceptional corrosion resistance and rust prevention capabilities.

What We Do

- Plate

- Sheet

- Forgings

- Round Bar

- Flange

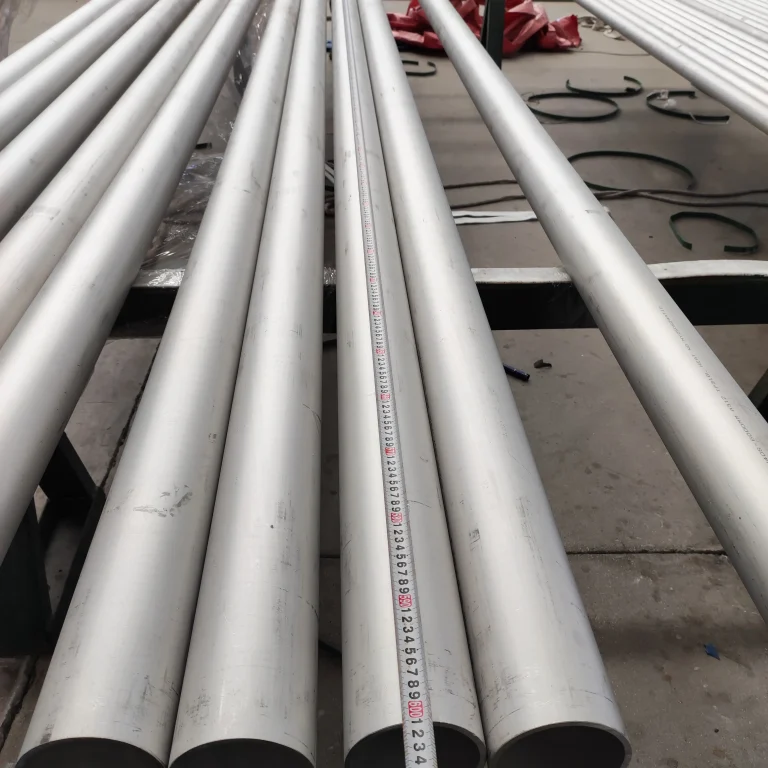

- Pipes

- Fittings

- Customized

Contact Us For More Information

Stainless Steel Pipes Benefits

The protective chromium oxide film provides effective resistance to chemical corrosion,which is crucial in humid,high-temperature or weakly acidic environments.This material minimises the risk of pitting and intergranular corrosion.

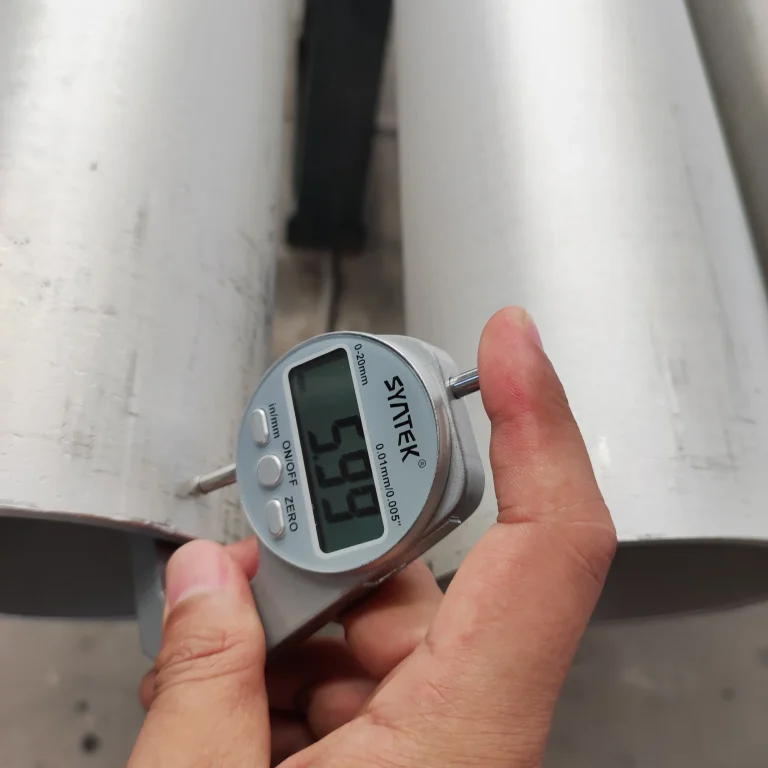

Stainless steel possesses high tensile and yield strength.It maintains its structural integrity under extreme pressure and heat.Reducing the risk of rupture or fatigue failure.

This alloy possesses rust-resistant properties,requiring minimal cleaning and maintenance.This eliminates the need for painting or protective coatings,significantly reducing maintenance costs throughout the system’s service life.

The smooth,non-porous surface effectively prevents bacterial adhesion and facilitates efficient disinfection and cleaning.This characteristic is a mandatory requirement for pharmaceutical and food contact applications.

Stainless Steel Pipes Drawbacks

Stainless steel is more expensive than carbon steel.This is due to the cost of alloying elements like chromium and nickel.The long-term durability,however, often justifies this increased investment.

Stainless steel conducts heat more slowly than copper or aluminium.This may impact heat exchange efficiency in certain applications.Designers must account for this characteristic when formulating the system geometry.

High levels of chloride ions can compromise the passivation layer,leading to localised pitting corrosion,particularly pronounced in stagnant areas.For marine use, high-molybdenum steel grades must be selected.

Welding alters the internal structure of metals,necessitating strict temperature control and post-weld treatment.Improper welding procedures can reduce the corrosion resistance of metals.

Applications in Industrial Piping

Chemical Processing

Chemical plants rely on high-grade stainless steel.The material resists corrosive acids,including sulfuric and nitric compounds.Grade 316L is common for its stability and resistance to intergranular corrosion.Duplex grades are used for highly aggressive media.

Food and Beverage

Hygiene is paramount in this sector.Stainless steel’s smooth surface meets strict sanitary standards.Piping is used for product lines,storage tanks,and clean-in-place (CIP) systems. This prevents contamination and ensures product purity.

Oil and Gas Refining

Refineries utilize stainless steel for transport.The material withstands high temperatures and pressures.It is essential for managing corrosive crude oil derivatives.Specialized fittings handle immense pressure safely.

Water Treatment

Pipelines transport chemicals such as chlorine and ozone.Stainless steel offers long-term resistance to water corrosion,making it an ideal choice for desalination plants and municipal water supply systems.

Maximizing Stainless Steel Pipes Benefits through Grade Selection

| Grade Category | Key Feature | Primary Benefit | Sample Application |

|---|---|---|---|

| 304 / 304L | General purpose | Cost-effective | Food Processing |

| 316 / 316L | Molybdenum Content | Chloride Resistance | Marine, Chemical |

| Duplex (2205) | High Strength | Pressure Handling | Offshore Risers |

| Martensitic (410) | High Hardness | Wear Resistance | Valve Stems |

Stainless Steel Pipes Benefits:Fabrication and Lifespan

| Benefit Area | Stainless Steel Pipe Benefits | Impact on Pipe System |

|---|---|---|

| Fabrication | Excellent Weldability | Fast, Reliable Jointing |

| Maintenance | No Protective Coatings Needed | Reduced Upkeep Costs |

| Durability | High Impact Resistance | Fewer Replacements |

| Thermal | High Heat Resistance | Stable Under Thermal Cycling |

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/