What is Flange Rust

Flange rust is a serious problem in many industrial systems. It directly impacts the safety and efficiency of piping networks.Therefore, protecting your stainless steel flanges is crucial.This is true for systems using stainless steel pipes and stainless steel pipe fittings.Understanding why corrosion happens is the first step. Proper material selection is key to preventing flange failure.

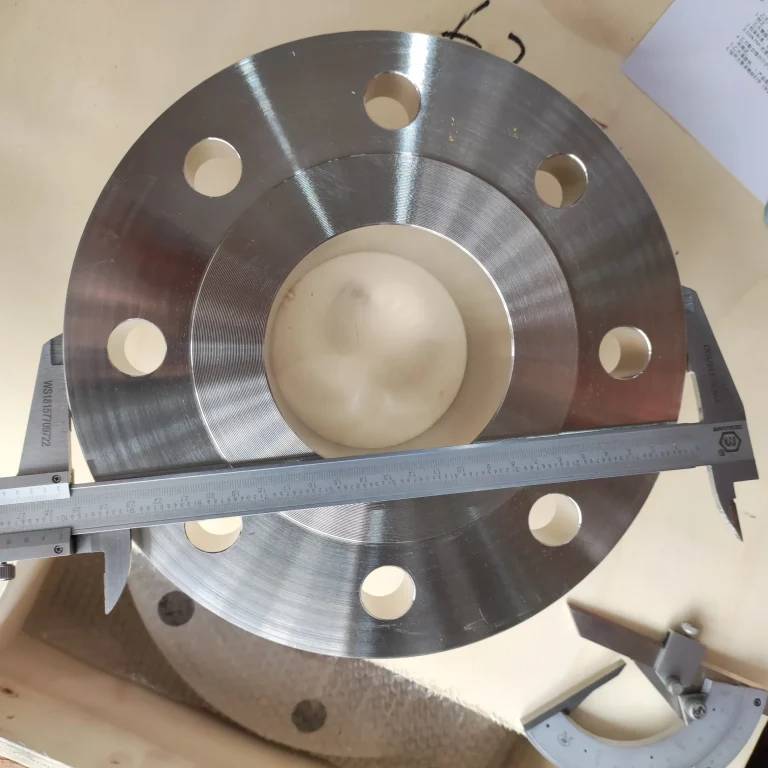

What is A Flange

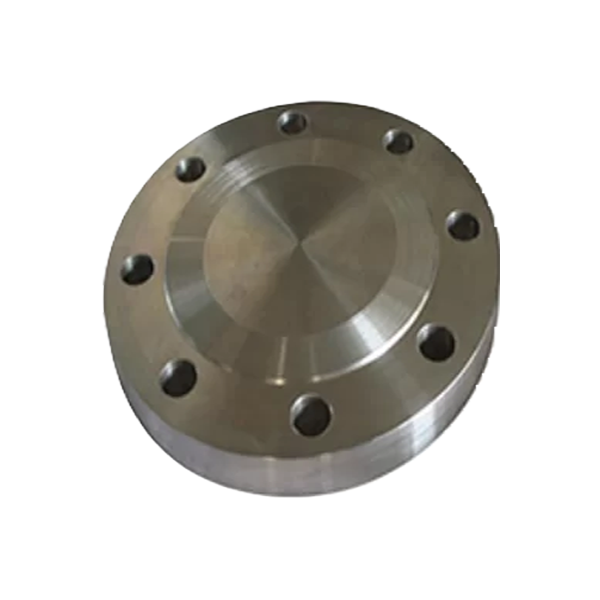

Flanges are a type of connection used to join pipes,valves,and other equipments. They form a secure, leak-proof seal and are widely used across numerous industries.This connection method is both safe and reliable,while also facilitating easy disassembly.Flanges are manufactured from various materials selected for their strength and corrosion resistance.

What We Do

- Pipes >

- Fittings >

- Flanges >

- More >

Key Disadvantages of Flange Rust

Flange rust can cause pitting and cracking thereby weakening the flange’s strength.It reduces the flange’s ability to handle pressure.Therefore, it may lead to sudden failures. A weakened flange is a serious safety risk.

Flange rust degrades the sealing surface. This creates pathways for leaks. Leaks of process fluid can be dangerous. They cause environmental and safety hazards. This contamination also leads to system inefficiency.

The effects of flange rust lead to more frequent inspection. They require costly repairs or full replacement. This results in significant unplanned downtime. These costs add up over time.

Ultimately, flange rust shortens the lifespan of your entire system. It forces premature component replacement. This corrosion can spread to connecting pipes. The entire system may need a complete overhaul. This is much more expensive.

Selecting Materials to Combat Flange Rust

Chemical Composition by Material

| Material | Fe | Cr | Ni | Mo | Other Elements |

|---|---|---|---|---|---|

| 304 Steel | Bal. | 18.0 – 20.0 | 8.0 – 10.5 | – | C: ≤0.08, Si: ≤1.0, Mn: ≤2.0 |

| 316L Steel | Bal. | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | C: ≤0.03, Si: ≤1.0, Mn: ≤2.0 |

| Titanium | Bal. | – | – | – | Ti: ≥99.2, N: ≤0.03, H: ≤0.015, Fe: ≤0.3, O: ≤0.25 |

| Aluminum | 0 – 0.7 | 0.04 – 0.35 | – | – | Al: Bal., Mg: 0.8-1.2, Si: 0.4-0.8, Cu: 0.15-0.4 |

Mechanical Properties by Material

| Property | 304 Steel | 316L Steel | Titanium | Aluminum |

|---|---|---|---|---|

| Tensile Strength (MPa) | ≥515 | ≥485 | ≥345 | ≥275 |

| Yield Strength (0.2% Offset) (MPa) | ≥205 | ≥170 | ≥275 | ≥240 |

| Elongation (%) | ≥40 | ≥40 | ≥20 | ≥10 |

What We Do

- Pipes >

- Fittings >

- Flanges >

- More >

Flange Applications in Piping Systems

Flanges in these systems face highly corrosive acids and chemicals.316L stainless steel is a popular choice.Its molybdenum content provides strong corrosion resistance.It is often used for stainless steel pipe fittings in chemical plants.

These environments have high chloride content.Seawater is very corrosive.Therefore, titanium flange is a great option.They offer superior resistance to pitting and crevice corrosion.This ensures system reliability and long life.

The flange in oil and gas industry operates under extreme pressure and temperature. Flanges must withstand corrosive hydrocarbons and harsh downhole conditions. High-grade alloys are essential to prevent flange rust and catastrophic failures.

For less aggressive environments,304 stainless steel flanges are common.They offer a great balance of cost and corrosion resistance.They are suitable for many stainless steel pipe applications.

A aluminum flange is often used in this industry.They are chosen for their light weight and moderate strength.They are suitable for lower-pressure applications.Weight is a primary design concern.

How to Prevent Flange Rust

- Choose the Right Material:This is the most important step.Select a flange material resistant to your specific operating environment.For example, use 316L stainless steel to prevent flange rust in marine conditions.For extremely aggressive chemicals, titanium is a better option.

- Apply Protective Coatings:Coatings create a barrier.They separate the flange material from corrosive elements.Zinc-rich coatings,paints,or specialized anti-corrosion wraps can be applied.This is an effective way to stop flange rust on carbon steel flanges.

- Implement a Maintenance Schedule:Regular inspections are crucial.Look for early signs of flange rust,such as pitting or discoloration.Address these issues immediately with cleaning or repair.This stops the spread of flange rust and extends the flange’s life.

- Ensure Proper Installation:A tight, well-installed flange connection is essential.Use the correct flange gasket and bolts.A poor seal allows moisture and corrosive fluids to seep in.This can cause severe flange rust on the sealing surface.

- Control the Environment:When possible, manage the environment around the flanges.Use dehumidifiers in high-moisture areas. Insulation can also prevent condensation from forming on flange surfaces.These measures help to fight flange rust before it begins.

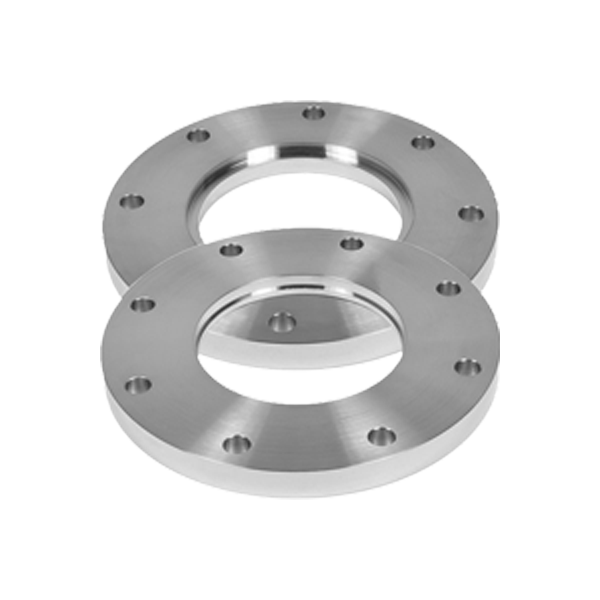

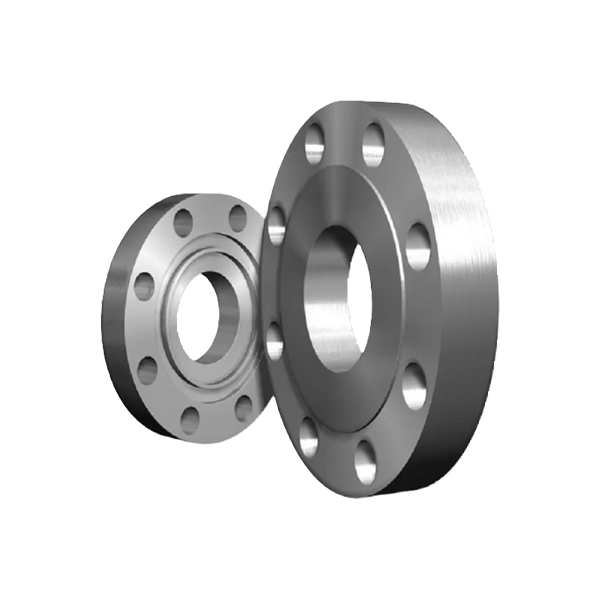

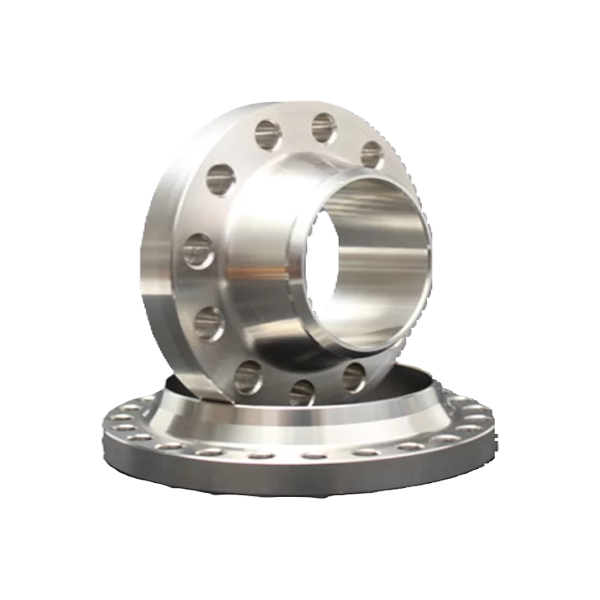

Flanges We Offer

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/