A stainless steel heat exchanger is a highly efficient heat transfer devices.These critical systems are employed to transfer thermal energy between two distinct fluids.Crucially,these two fluids must never undergo physical mixing.

The equipment is renowned for its durability and corrosion resistance,rendering it an excellent choice for harsh environments.

The Role of a Stainless Steel Heat Exchanger

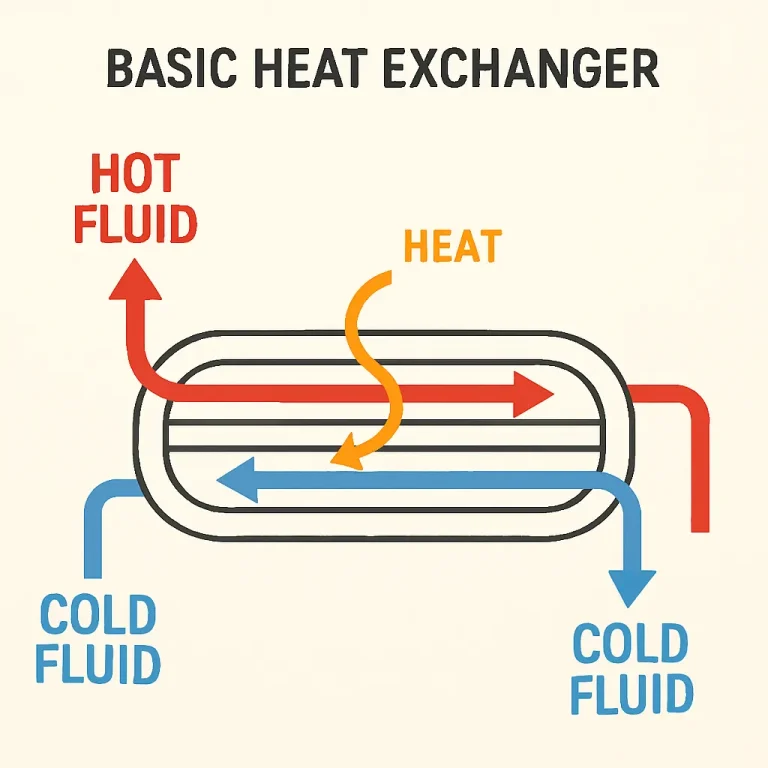

A heat exchanger is fundamental to thermal management.It moves heat from a warmer fluid to a cooler one.This process is necessary for heating,cooling,or recovering energy.Stainless steel construction ensures integrity.It allows the heat exchange to occur reliably under pressure.High performance is maintained even with corrosive process fluids.

Working Principle

- Separation: One fluid flows on one side of the barrier.The second fluid flows on the opposite side.This keeps the two media physically apart.

- Conduction: Heat moves through the solid stainless steel wall.Thermal energy travels from the hotter fluid to the cooler one.Stainless steel provides the necessary thermal transfer area.

- Flow Types: Fluids move in different ways to maximize transfer.Counter-current flow is the most efficient design.The fluids enter the exchanger from opposite ends.

What We Do

- Plate

- Sheet

- Forgings

- Round Bar

- Flange

- Pipes

- Fittings

- Customized

Contact Us For More Information

Features

- Corrosion Resistance: Stainless steel’s primary advantage lies in its resistance to corrosion.It can withstand highly corrosive chemicals. Grades such as 316 and duplex steel resist acid erosion.

- High Mechanical Strength: This material resists deformation under high pressure,maintaining structural integrity.

- Hygienic Surface: Its smooth,non-porous surface facilitates cleaning,inhibits bacterial growth and prevents dirt adhesion,making it essential for sanitary applications.

- Durability: Stainless steel exhibits resistance to thermal expansion and fatigue,ensuring prolonged service life and reducing the need for frequent replacement.

Advantages

- Chemical Compatibility: SS prevents chemical corrosion of metal surfaces.

- Long Service Life: The passivated oxide layer protects the material from rusting.

- Design Flexibility: Stainless steel can be applied to various structural forms, including shell-and-tube or plate heat exchangers.

- High-temperature Resistance: Most stainless steel grades retain their strength in high-temperature environments.

Disadvantages

- Thermal conductivity: Stainless steel conducts heat more slowly than other metals.

- Higher initial cost: Stainless steel equipment carries a higher initial cost than carbon steel.

- Welding sensitivity: Certain stainless steels exhibit sensitivity to welding heat,potentially requiring appropriate post-weld treatment.

- Scaling tendency: Stainless steel may accumulate water scale,requiring periodic cleaning and maintenance.

Stainless Steel Heat Exchanger Common Grades

This table details common stainless steel grades used for heat exchanger tubing. The material choice depends on the fluid’s corrosivity.

| Grade | Key Feature | Best For |

|---|---|---|

| 304 Steel 304L Steel | General use | HVAC, low pressure |

| 316 Steel 316L Steel | Chloride resistance | Chemical, food processing |

| Duplex 2205 | High strength | Oil & Gas, high pressure |

| 904L Steel | Excellent acid resistance | Sulfuric acid applications |

Stainless Steel Heat Exchanger Types

| Type | Design Focus | Key Application |

|---|---|---|

| Shell & Tube | High pressure | Power plants, refineries |

| Plate | High efficiency | Food, beverage, HVAC |

| Spiral | Viscous fluids | Slurry processing |

Stainless Steel Heat Exchanger Applications

- Food and Beverage: Exchangers are used for pasteurization and cooling.Hygiene is non-negotiable in this industry.The smooth stainless surface prevents contamination.

- Chemical Processing: Units withstand highly corrosive acids and chemicals.The Heat exchanger coiled tube design is often used.It maximizes surface area in a small space.

- Pharmaceutical Industry: High-purity systems rely on precise temperature control.Stainless steel ensures that no contamination occurs.It meets stringent regulatory requirements.

- Power Generation: They are used in condensers and heat recovery systems.Stainless steel heat exchanger systems handle high pressure and high temperature. They are vital for system efficiency.

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/