Nimonic 75 is a reliable solution for extreme temperatures. The heat resistance of this high-performance alloy is far superior to standard stainless steels. Its unique properties are critical to long-term durability. Choosing Nimonic 75 ensures that your critical stainless steel pipes and stainless steel pipe fittings maintain their strength and functionality.

Nimonic 75 | UNS N06075

Nimonic 75 is a nickel-based alloy belonging to the group Nimonic Alloy, which contains about 20% chromium and therefore has excellent oxidation resistance. It has good mechanical properties at high temperatures.

Key Strengths of Nimonic 75

Nimonic 75 is oxidation resistant and can withstand continuous operating temperatures up to 980°C (1795°F).

Maintains strength at elevated temperatures for reliable performance. It is not designed to resist creep deformation. However, it has good mechanical integrity in many applications.

Nimonic 75 is easy to mold, easy to weld, and handles complex fabrications well.

It retains its properties when subjected to heat and does not rapidly lose strength, making it ideal for high temperature applications.

Chemical Composition

| Element | Ni | Cr | Fe | C | Ti | Cu | Mn | Si |

|---|---|---|---|---|---|---|---|---|

| Content (wt%) | Balance | 18.0-21.0 | 5.0 Max | 0.08-0.15 | 0.20-0.60 | 0.5 Max | 1.0 Max | 1.0 Max |

Mechanical Properties

| Property | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Hardness | Density | Melting Range |

|---|---|---|---|---|---|---|

| Value (Typical) | ≥690MPa(100ksi) | ≥275MPa(40ksi) | ≥30 | 200 Max | 8.26g/cm³ | 1370−1420 ℃ |

Nimonic 75 in High Temperature Piping Systems

- Flame Tubes: They can withstand high heat and can be used for flame tubes.

- Exhaust Systems: They can handle hot gas streams, resist oxidation and corrosion, and can be used in exhaust manifolds.

- Pipes and Bellows: These materials can withstand thermal cycling and are made into high-temperature pipes and expansion bellows.

- Furnace Components: Withstand sustained high temperatures and prevent scaling for furnace linings and shrouds.

- Piping Systems: These can be used for critical stainless steel fittings where extreme heat resistance is required.

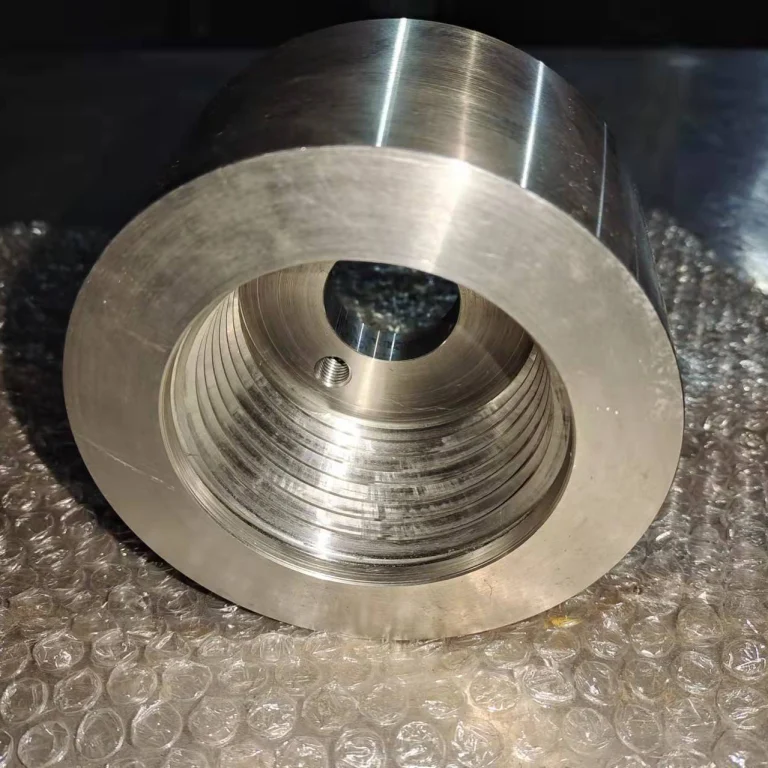

Sourcing and Fabricating Nimonic 75

A complete Material Test Report (MTR) is required. It verifies the precise composition of the alloy and ensures its performance.

Work with specialized suppliers of stainless steel pipe and fittings. They understand these alloy steels and can ensure proper fabrication and quality control,and are ISO 9001 and CE-PED certified.

It is difficult to machine and requires special tools. Specific welding techniques are essential to ensure the integrity of the weld.

It is expensive, so it is important to assess whether the product has a longer service life. This can justify its higher initial cost.

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/