ISO 9001 and CE-PED certification are essential for stainless steel pipes and fittings. Uncertified materials pose significant risks that can affect safety, performance and compliance. Having the ability to guarantee quality through these standards ensures reliable performance of stainless steel pipe and fittings.

What are ISO 9001 and CE-PED? Cornerstones of Quality!

ISO 9001 and CE-PED are vital certifications that signify product excellence and compliance.

- ISO 9001: This is an international standard that defines the requirements for a quality management system. It helps companies to consistently meet customer needs. For pipes and fittings, this means systematic quality control.

- CE-PED: Stands for ‘CE marking’ in the Pressure Equipment Directive and is a mandatory certification for pressure equipment in the European Union. Ensures that products comply with EU safety requirements.

Why ISO 9001 and CE-PED Matter to You

Stainless steel pipework and fittings operate in critical systems where they handle pressures, temperatures and corrosive media, and where any failure could have serious consequences. Certifications such as ISO 9001 and CE-PED provide vital reassurance. Providing confidence in product performance and ensuring market access, particularly in Europe.

ISO 9001 means consistent manufacturing processes. Products like stainless steel pipe and fittings meet specifications reliably. This reduces defects and ensures long-term performance.

CE-PED certification confirms product safety. It ensures pressure equipment, like fittings, meets stringent EU directives. This minimizes operational risks and potential liabilities for your company.

Partnering with certified suppliers simplifies vetting. ISO 9001 and CE-PED act as pre-qualifiers. This saves time and resources in your procurement workflow.

Using certified stainless steel pipe and fittings means fewer failures. This translates to less downtime. It avoids costly repairs. It also prevents potential accidents.

Products with ISO 9001 and CE-PED compliance are recognized worldwide. This opens doors for international projects. It ensures your supply chain meets diverse regulatory demands.

ISO 9001: The Global Quality Standard

ISO 9001 is an internationally recognized standard that focuses on quality management systems. Obtaining ISO 9001 certification means that a company has robust processes in place to ensure consistent product quality and customer satisfaction.

- Key Focus: Customer satisfaction, process approach, continuous improvement.

- Requirements: Documented procedures, management responsibility, resource management, product realization, measurement, analysis, improvement.

- Rigor: Certification involves external audits. These verify adherence to the standard. It demands ongoing commitment to quality.

What We Do

CE-PED: European Pressure Equipment Directive

CE-PED is a mandatory European standard. It ensures the safety of pressure equipment. This includes stainless steel pipe and fittings. Products sold in the European Economic Area must comply.

- Focus: Safety, design, manufacturing, conformity assessment.

- Requirements: Classification based on fluid, pressure and volume. Conformity assessment modules (e.g. internal controls, type inspection, comprehensive quality assurance). Essential safety requirements.

- Stringency: PED compliance is legally binding and involves risk assessment. Notified Bodies usually certify high category devices.

Achieving Certification: A Rigorous Journey

Reliable stainless steel pipe and fittings manufacturers face tough challenges in getting certification. Obtaining ISO 9001 and CE-PED certification for stainless steel pipes and fittings is extremely challenging and requires significant investment and commitment.

The company must establish detailed documentation covering all quality processes, including design, production and testing procedures. Each step must be clearly defined and documented.

The production process requires fine control, including material traceability. Precise production parameters are ensured. Consistent quality is maintained from the raw material to the final product.

The products undergo comprehensive testing including material analysis, mechanical property verification, and stress testing to ensure product performance under load, thus ensuring the integrity of the product.

Certification is not a one-off event and organisations must continually improve their processes. This ensures continued compliance, increased efficiency and effective handling of customer feedback.

Independent auditors are responsible for verifying compliance. They conduct thorough on-site inspections. This impartial assessment confirms that the product complies with the standard and gives confidence in the manufacturer’s competence.

Certification Focus: Quick Comparison

| Feature | ISO 9001 | CE-PED |

|---|---|---|

| Scope | Quality Management System | Product Safety (Pressure) |

| Mandatory | Voluntary | Mandatory (EU Market) |

| Focus | Process Quality | Product Safety & Design |

| Audit Body | Certification Body | Notified Body (Often) |

ISO 9001 and CE-PED Certified Supplier: A Smart Sourcing Strategy

When sourcing stainless steel pipe and fittings, always prioritise certified suppliers and streamline your internal processes. Minimise your liability. Ensure products meet global safety and quality benchmarks. You are investing in reliability and peace of mind.

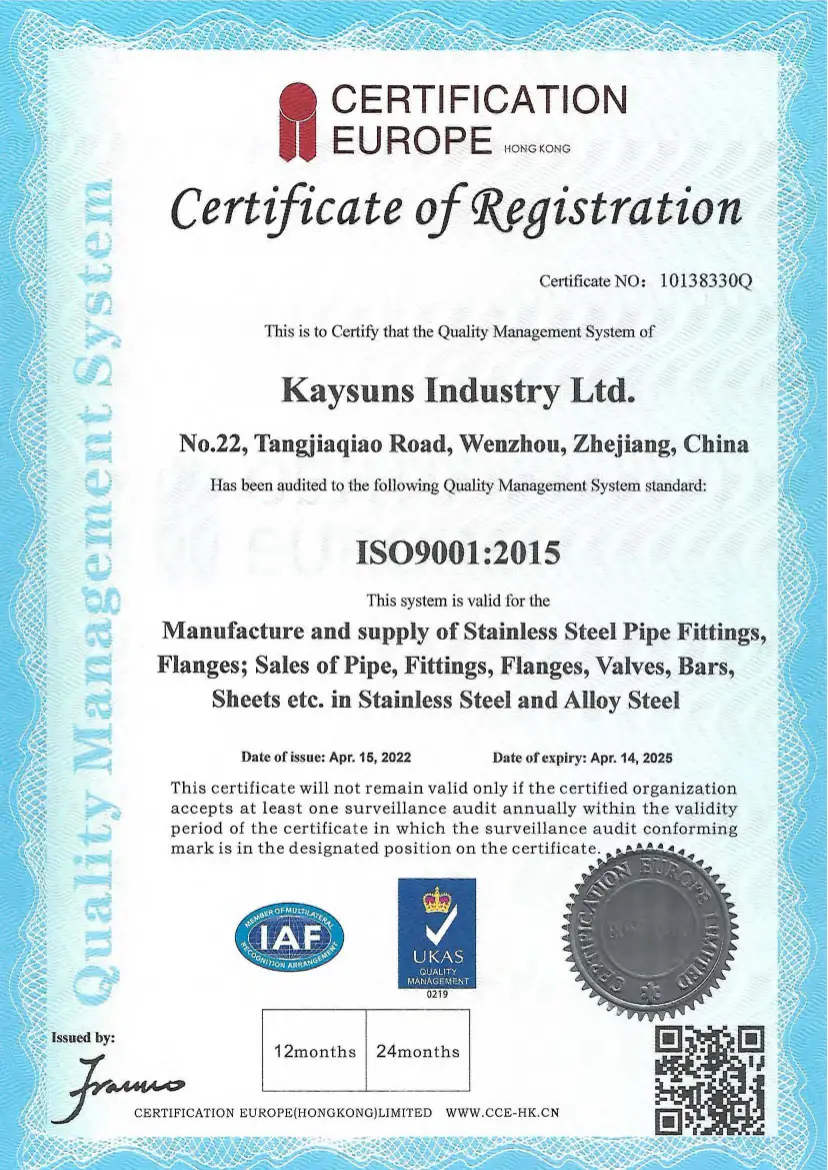

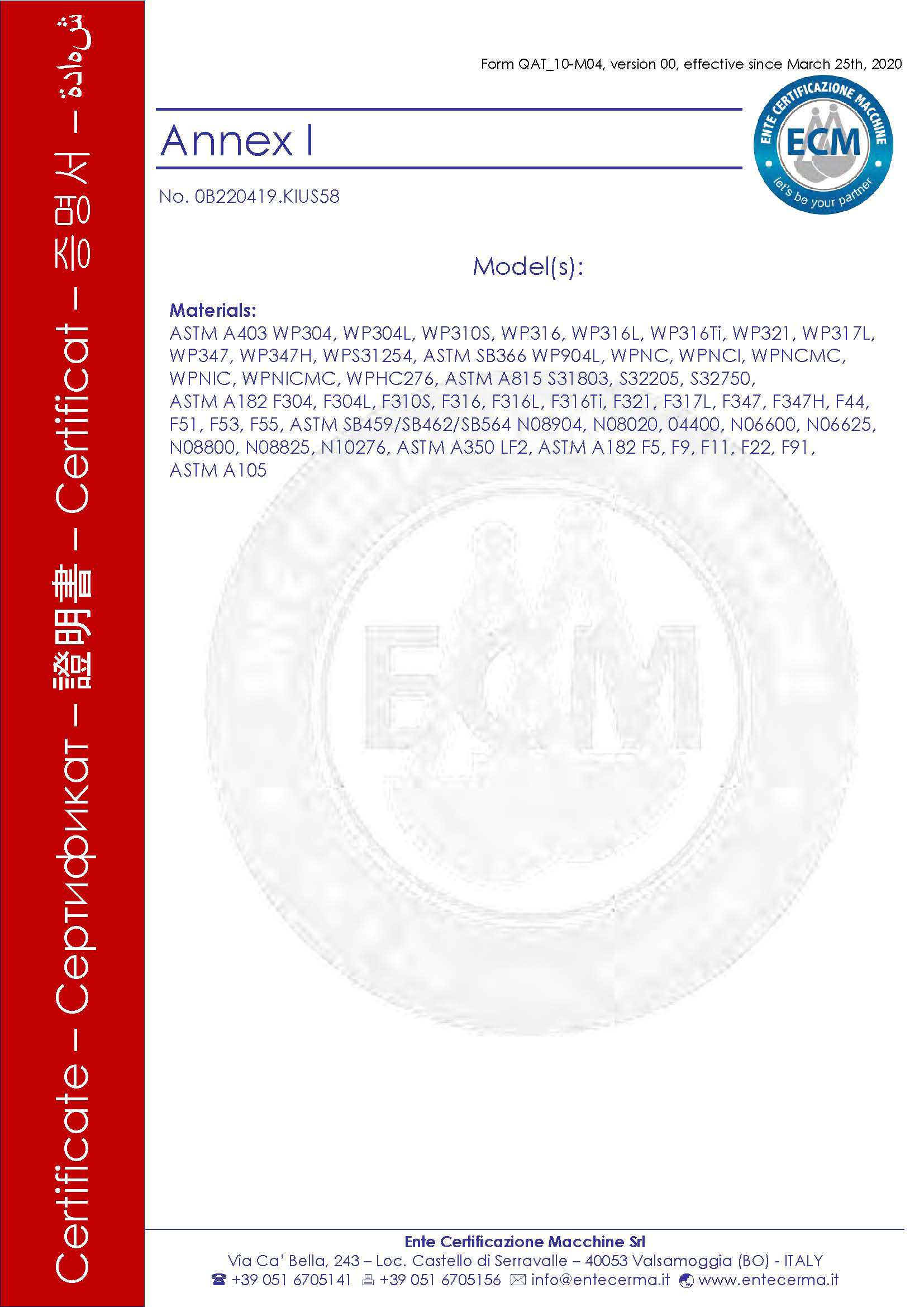

You May Also Want To View All Certificates

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/