What’s Hastelloy and its Cutting Characteristics?

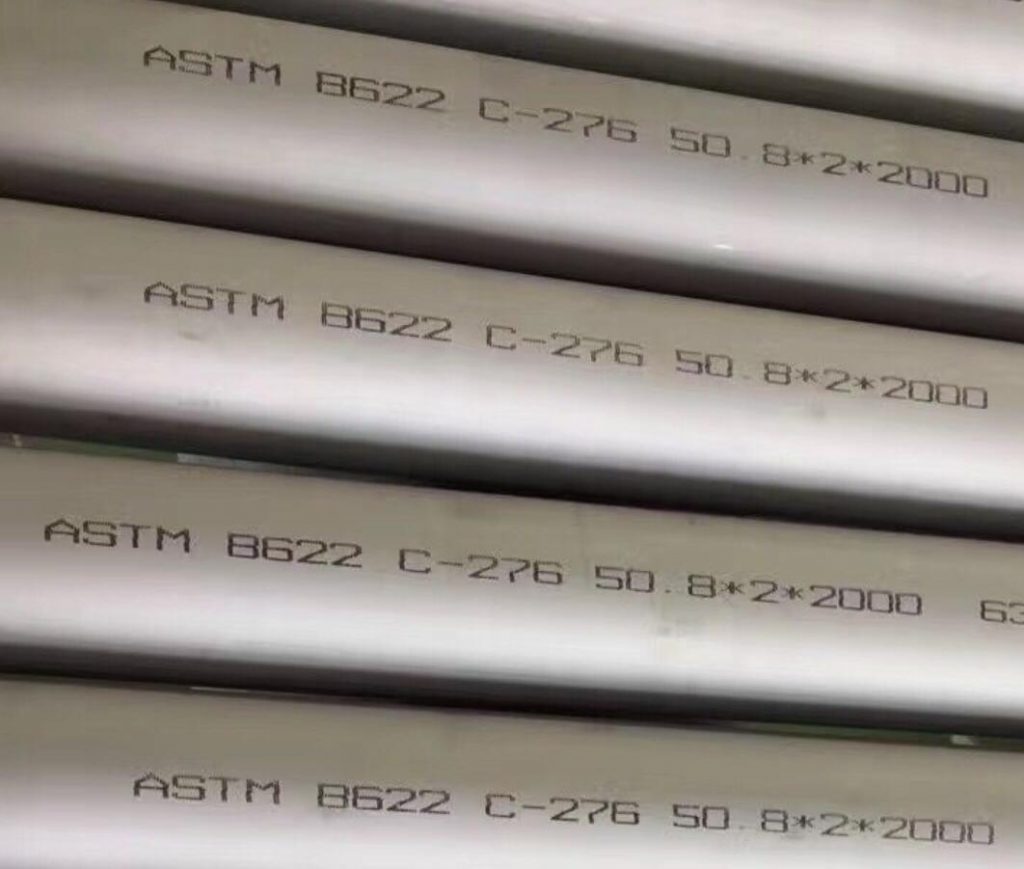

Hastelloy itself is a nickel-based alloy, but different from ordinary pure nickel (Ni200) and Monel, it uses chromium molybdenum as the main alloying element, and aims to improve the adaptability to various media and temperatures, and is targeted at different industries.

The chemical industry generally pursues high production capacity to increase the temperature and pressure to speed up the reaction speed, so that production is prone to unpredictable conditions and cause unscheduled maintenance.

Hastelloy is designed to meet such a demand, adapting to various unforeseen harsh environments and minimizing unscheduled maintenance. At the same time, it also has good processing and welding performance, which is convenient for field maintenance.

Here we introduce several cutting characteristics of Hastelloy steel pipe:

1. The hardening situation is more serious during processing: the most prominent are austenite and austenite + ferritic hastelloy steel pipes,

Because hastelloy steel pipe has a large plasticity, it is easy to be twisted during plastic deformation, and the coefficient of strengthening is large. In addition, the stability of austenite is weak, and part of the austenite becomes martensite under cutting; under the action of cutting heat, the easily decomposable compound impurities are diffusely distributed, and a hardened layer will occur at this time.

The hardening phenomenon generated during processing will affect the subsequent process.

2. Large cutting force is required: Because the plasticity of the Hastelloy steel pipe during cutting is large, its cutting force is increased. The austenitic Hastelloy steel pipe performs particularly well, and its elongation is 1.5 times higher than that of 45 steel Times. Because Hastelloy steel pipe has a severe hardening effect during processing, higher thermal strength, its cutting resistance is increased, it is more difficult to break the cutting curl;

3, The cutting temperature is higher: the heat generated during cutting is more due to the greater friction between the plastic deformation and the tool; Hastelloy steel pipe heat dissipation is slower during cutting, most of the heat is concentrated in the cutting area The interface with the cuttings, and its thermal conductivity is only 1/2 ~ 1/4 of 45 # steel;

4. Hastelloy steel pipe is not easy to be broken and easy to bond when cutting: This also shows that Hastelloy steel pipe has great plasticity and toughness.

Especially during processing, continuous cutting is easy to crush the surface of Hastelloy steel pipe and it will also affect the operation process. Under high temperature and high pressure, it is easy to produce adhesion with other metals, forming swarf, increasing the wear of the tool, and causing the surface to tear.

5. Easy-wearing tools: The wear generated by the tools during cutting is easy to stick and spread, causing crescent pits on the rake face of the tools, while the cutting edges form tiny spalling and gaps, and carbides in Hastelloy steel pipes Particles have high hardness, and hardening during processing will accelerate tool wear;

6. Hastelloy steel pipe has a large linear expansion coefficient: only 1.5 times that of carbon steel. At the cutting temperature, it is difficult to control the accuracy of the size due to thermal deformation.