Inconel 617 is a powerful nickel-chromium-cobalt-molybdenum alloy.It offers an incredible combination of high-temperature strength and corrosion resistance.Therefore,it is ideal for systems where standard stainless steel pipes and stainless steel pipe fittings would fail.This superalloy provides a superior solution.It works perfectly in extreme heat and harsh environments.

Introduction to Inconel 617 | UNS N06617

Inconel 617 is a specialized material. Its unique composition gives it amazing properties.It maintains its strength at very high temperatures and also resists oxidation and various corrosive media.The addition of cobalt and molybdenum is key to provide exceptional strength.They also improve resistance to high-temperature corrosion.Inconel 617 is a top choice for critical components.

Key Advantages of Inconel 617

This alloy delivers outstanding performance under extreme heat, effectively resisting creep deformation and stress corrosion cracking, making it an ideal choice for high-temperature environments.

The alloy effectively prevents scale formation and oxidation reactions, performing exceptionally well in hot air and combustion product environments, significantly extending the service life of all components.

Withstands diverse corrosive media, demonstrating excellent tolerance to acids, alkalis, and saltwater, ensuring reliable performance under harsh operating conditions.

Simplifies welding operations while preserving material properties post-weld, greatly streamlining the manufacturing process for complex piping and fittings.

Key Disadvantages of Inconel 617

The alloy composition includes expensive elements such as nickel, cobalt, and molybdenum, which drive up the price, making it more costly than standard stainless steel.

Inconel 617 is relatively heavy, and its high density increases the overall system weight, which may pose a limiting factor in certain project designs.

As a specialty alloy, its market availability may be restricted, potentially leading to extended project delivery cycles.

This alloy exhibits extreme hardness, making machining challenging. It requires specialized tools and advanced technical expertise.

Chemical Composition

| Element | Ni | Cr | Co | Mo | Al | Fe | Mn | Si | C | S |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (wt%) | Bal. | 20.0 – 24.0 | 10.0 – 15.0 | 8.0 – 10.0 | 0.8 – 1.5 | ≤3.0 | ≤0.5 | ≤0.5 | 0.05 – 0.15 | ≤0.015 |

Mechanical Properties

| Property | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Hardness | Density |

|---|---|---|---|---|---|

| Value (Typical) | ≥750MPa(109ksi) | ≥345MPa(50ksi) | ≥30 | ≤92 | 8.36g/cm³ |

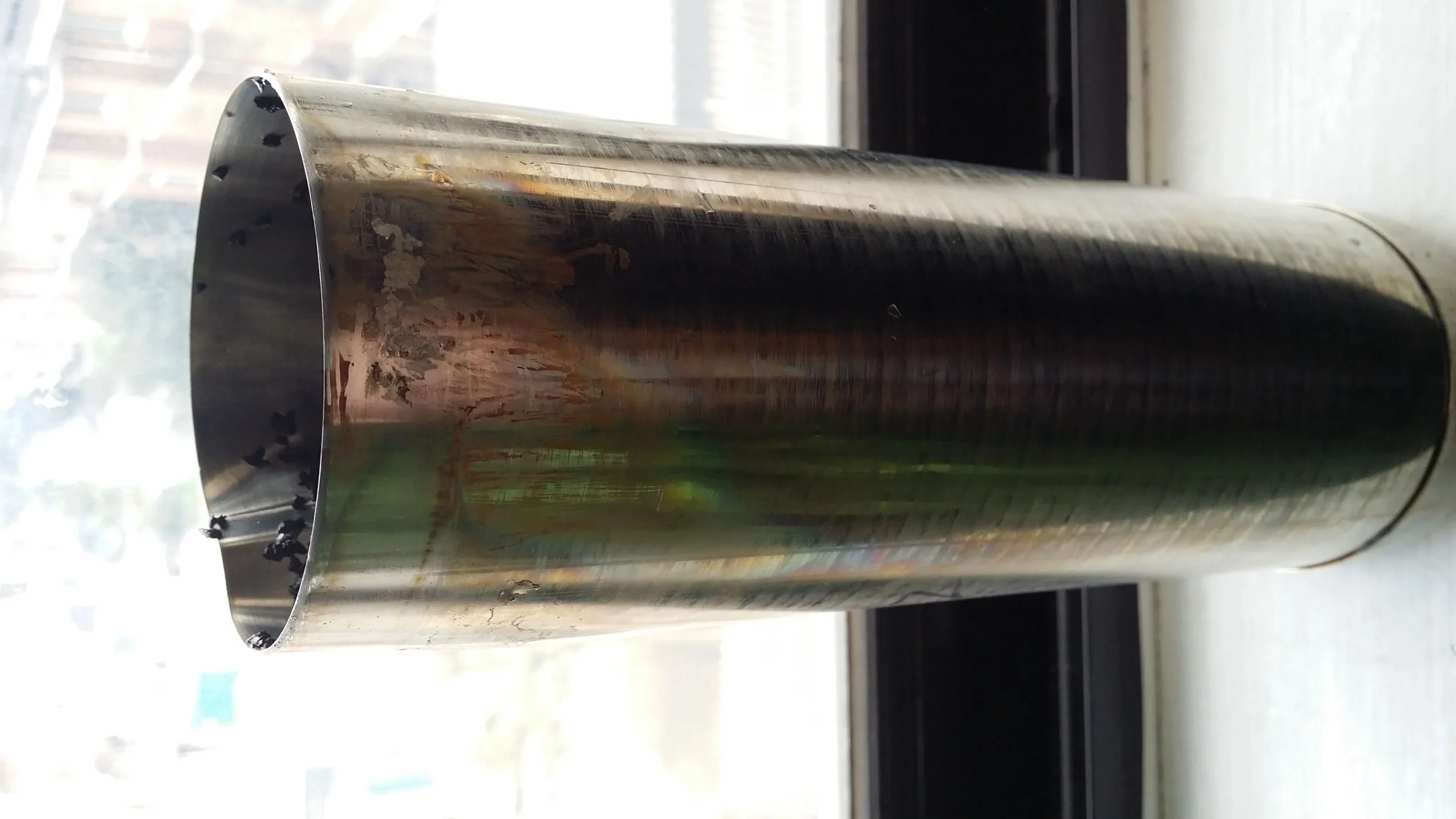

Inconel 617 in Pipes and Fittings

- High-temp Components: For critical stainless steel pipe fittings, Inconel 617 provides extreme strength. It keeps your system working perfectly in high heat. The alloy handles temperatures with ease.

- Heat Exchangers: The alloy is perfect for heat exchanger tubing. It withstands highly corrosive and hot fluids. This ensures efficient and safe operation.

- Power Generation: Inconel 617 is an excellent choice. It is ideal for systems in gas turbines and power plants. Its resistance to heat and pressure is key.Ensures longevity and reliability of pipes and fittings.

- Aerospace: It is essential for pipes and fittings in the aerospace industry. Inconel 617 handles high heat and stress. The alloy maintains its integrity, prevents leaks and costly downtime.

Sourcing and Fabricating Inconel 617

Always request a Material Test Report (MTR). This document confirms the chemical composition and mechanical properties of the material. The MTR ensures the authenticity and reliability of the specific alloy steel batch you receive and verifies its compliance with required specifications.

Select a professional stainless steel pipe and fittings supplier. Choosing suppliers certified to ISO 9001 and CE-PED ensures peace of mind. ISO 9001 certification demonstrates commitment to quality management systems, while CE-PED certification verifies compliance with European market safety standards for pressure equipment.

This alloy requires specific welding and fabrication techniques. High molybdenum content can cause issues if mishandled, making standardized procedures critical. Ensure your team masters proper handling methods, and welders use compatible filler materials and techniques to prevent risks like hot cracking or reduced corrosion resistance.

While Inconel 617 alloy carries a higher initial cost, its service life far exceeds that of standard alloys. Exceptional durability significantly reduces long-term maintenance and repair expenses while preventing unexpected system failures. The substantial savings from extended service life deliver a high return on the initial investment in Inconel 617.

You May Also Want To Read:

What is Inconel 690 / N06690 And Why It Matters

Inconel 601 (2.4851): Guardian of Industry

Nickel Alloy Inconel 718

Inconel vs Incoloy vs Monel

What is Inconel 625 ?

How Does Incoloy 925 Protect Critical Piping Systems?

Inconel 600 | Specifications | Applications | Get Free Fast Quote

What is Inconel X750 ?

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/