Inconel 600 provides a reliable solution for high-temperature needs. Standard stainless steel often lacks the needed endurance. It also struggles with corrosion. This is where Inconel 600 offers a superior solution. Its properties are vital. It ensures your stainless steel pipes and stainless steel pipe fittings last.

What is Inconel 600 | UNS N06600

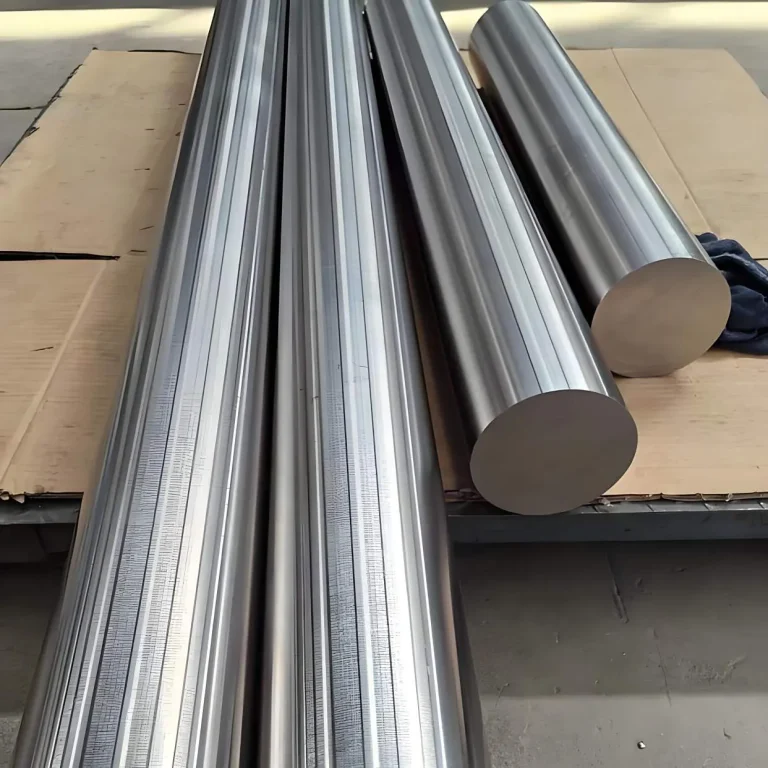

Inconel 600 pipe is a nickel-chromium alloy pipe with a nickel content of at least 72%.This gives it extremely high corrosion resistance at high tempratures.The alloy is a non-magnetic material with good mechanical properties,resistance to oxidation,and resistance to carburization.

What We Do

- Pipes >

- Fittings >

- Flanges >

- More >

Key Advantages of Inconel 600

Inconel 600 retains its strength at high temperatures and does not soften due to heat.

Its high nickel content protects against many corrosives.It resists various acids. It also battles chloride stress corrosion cracking. This extends component lifespan significantly.

Inconel 600 has outstanding corrosion resistance in high-temprature environments.Its chromium content forms a protective oxide layer,thereby preventing the formation of oxide scale.

This alloy is easy to form. It can be readily welded. This is crucial for complex fabrications. It ensures strong, reliable joints for piping systems.

Chemical Composition

| Element | Ni | Cr | Fe | Mn | Si | Cu | C |

|---|---|---|---|---|---|---|---|

| Content (wt%) | ≥72.0 | 14.0 – 17.0 | 6.0 – 10.0 | 1.0 Max | 0.50 Max | 0.50 Max | 0.15 Max |

Mechanical Properties

| Property | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Hardness | Density | Melting Range |

|---|---|---|---|---|---|---|

| Value (Typical) | ≥550MPa(80ksi) | ≥240MPa(35ksi) | ≥30 | ≤192 | 8.47g/cm³ | 1354−1413 ℃ |

Inconel 600 in Piping Systems

- Furnace Components: Radiant tubes and muffles. It withstands intense heat, resists carburization.

- Chemical Processing: Handling caustic alkalis and certain organic acids. It resists stress corrosion cracking.

- Nuclear Industry: Reactor components. It handles high-purity water, resists chloride attack.

- Aerospace: Engine parts and exhaust systems. It withstands intense heat and stress.

- Piping Systems: Key stainless steel pipe fittings. These parts need extreme heat resistance.

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/