Hastelloy C59 has amazing corrosion resistance. Standard stainless steel pipes and stainless steel pipe fittings often lack the required durability, especially in corrosive environments. This is where it provides an excellent solution.

What is Hastelloy C59 | UNS N06059 | 2.4605

Hastelloy C59 is a nickel-chromium-molybdenum alloy which belongs to the Hastelloy alloy family,Hastelloy C Series. With very low carbon and silicon content, it is resistant to sensitization of stainless steel. It is favorable for the manufacture of welded fittings.

What We Do

- Pipes >

- Fittings >

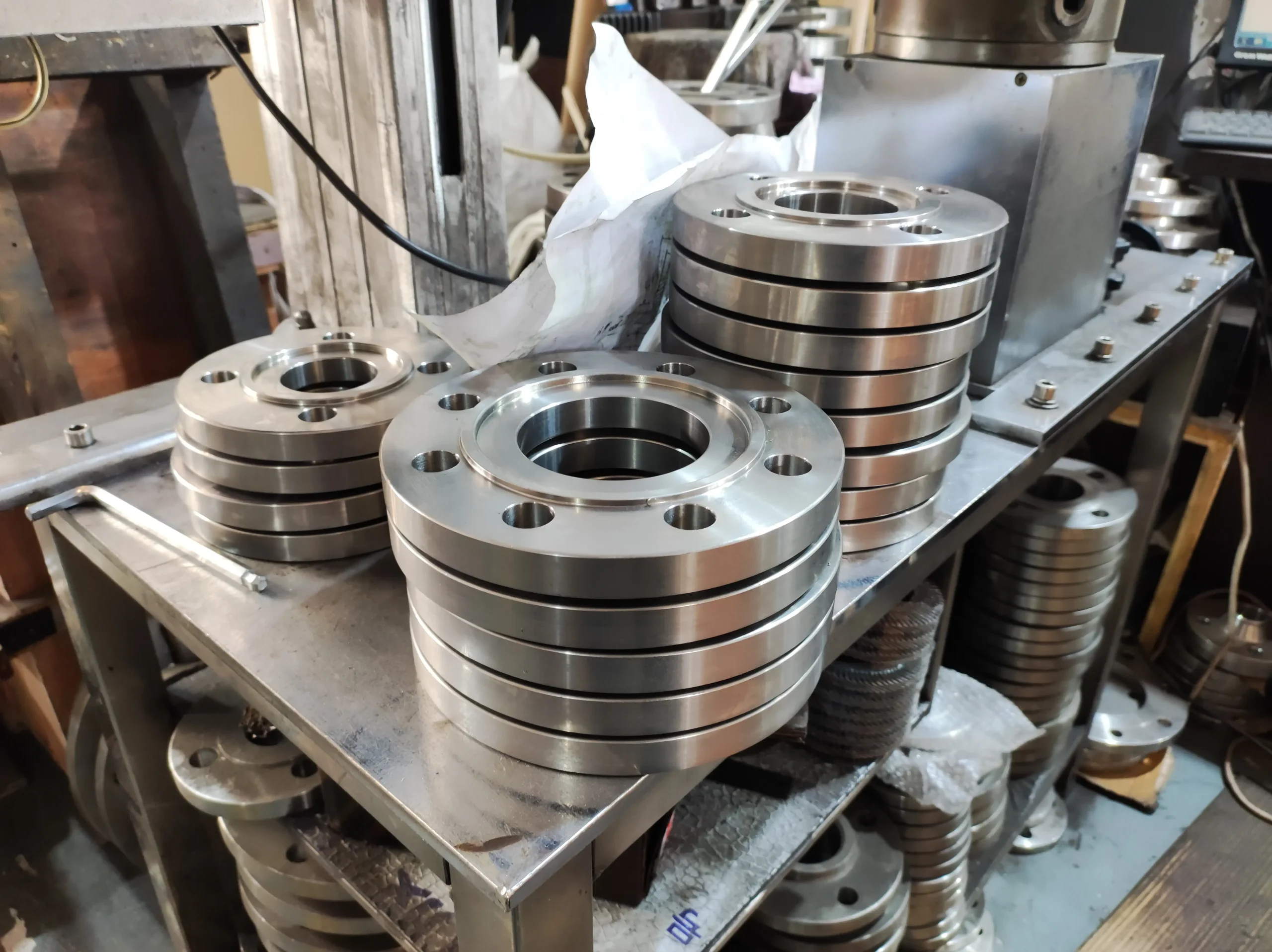

- Flanges >

- More >

Key Advantages of Hastelloy C59

Hastelloy C59 is resistant to a wide range of corrosive media, as well as oxidizing and reducing environments and stress corrosion cracking.

It is stable at high temperatures, preventing sensitization. Its corrosion resistance remains after welding.

Hastelloy C59 is easy to weld and easy to mold.

Hastelloy C59 is used in chemical processing, pollution control and food processing industries to handle acid gases and other corrosive media.

Chemical Composition

| Element | Ni | Cr | Mo | Fe | C | Si | Mn | Al |

|---|---|---|---|---|---|---|---|---|

| Content (wt%) | Balance | 22.0-24.0 | 15.0-16.5 | 1.5 Max | 0.01 Max | 0.05 Max | 0.50 Max | 0.20 Max |

Mechanical Properties

| Property | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Hardness | Density | Melting Range |

|---|---|---|---|---|---|---|

| Value (Typical) | ≥750MPa(109ksi) | ≥350MPa(51ksi) | ≥40 | ≤20 | 8.61g/cm³ | 1330−1375 ℃ |

Hastelloy C59 in High Pressure Piping Systems

- Chemical Processing: Highly corrosive environments, capable of handling strong acids and chlorides.

- Pollution Control: Flue gas desulphurization systems, which can handle highly corrosive acidic condensates.

- Agrochemical Industry: Handles a wide range of chemicals such as aggressive pesticides and fertilizers.

- High Temperature Systems: For shafts, valves and fasteners that maintain their properties at high temperatures.

- Piping systems: Critical stainless steel fittings require extreme corrosion resistance.

Contact Us

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/