Annual Output Value Reaches 10 Billion! Guangdong Yongjin’s Stainless Steel Phase I Has Been Completed 90%, Trial Production Next Month!

We carry out the cold rolling process independently, all relying on the upstream raw material support. Here in Yangjiang city, we must rely on the supply of Guangqing’s raw materials. Its raw material guarantee has great support for the supply of our customers. After the first phase of the project is fully operational, the monthly output will be close to 30,000 tons and the annual output will reach 300,000 tons. ” Said from Bi Xiangsheng, Executive Deputy General Manager of Guangdong Yongjin.

There is good news from Yangjiang city to build a 100 billion-level alloy materials industry.

Recently, the reporter visited Guangdong Yongjin and learned that the first phase of the Yongjin stainless steel cold rolling project is currently in the process of equipment installation. It is expected that trial production will be carried out next month. After the production is reached, it will become another important milestone for Yangjiang City to build a 100 billion-grade alloy material industrial cluster .

Entering the modern production workshop of Yongjin’s Stainless Steel Cold Rolling Project Phase I, a complete prototype of the production line is now available, and technicians are installing and debugging. As a cold rolling project, a cold rolling unit is essential.

At present, this giant with a value of more than 90 million yuan is a 20-roller reversible cold rolling unit independently developed by Guangdong Yongjin. It is characterized by high rolling precision, strong production capacity, and product quality that can reach the international advanced level of similar products.

It is understood that the entire production line of the first phase of the Jinjin Stainless Steel Cold Rolling Project is divided into feeding preparation, steel rolling, annealing and pickling, leveling, and coiling. The main equipment installation has been completed by 90%, and trial production is expected in the middle of next month .

It is worth mentioning that hydrogen peroxide is used as the pickling oxidant in the annealing and pickling section, and nitrogen oxides and nitrates are not produced during the production process, so it is cleaner and environmentally friendly.

Relevant persons in charge stated that they will rely on the hot-rolled stainless steel resources of Guangdong Guangqing Metal Technology Co., Ltd. and combine their advanced technology and management advantages in the cold rolling field to continuously enhance their competitiveness and contribute to the high-quality development of local economies.

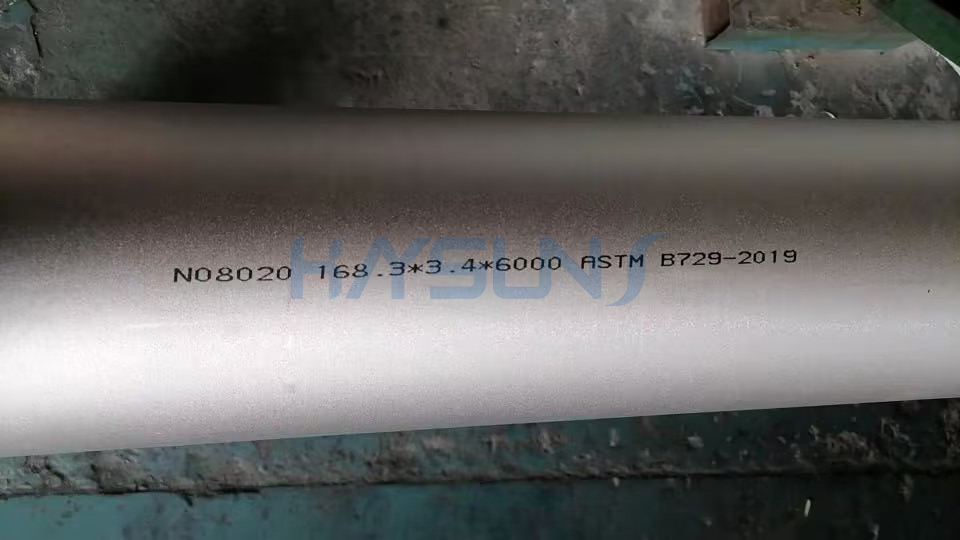

Posted by stainless steel tubing supplier and stainless steel pipe supplier KAYSUNS.