Application of Thin-Wall Stainless Steel Tubings in Indoor Gas Engineering Project

With the development of China’s economy, increasing number of new materials and technologies are widely used in gas pipeline engineering projects. Thin wall stainless steel tubings, a new construction material, now also has been widely applied for the construction of natural gas pipelines. For the companies engaged in natural gas industry, they shall perfect the management standard, pay more attention to the anti-corrosion treatment of the material, improve the intensity of inspection, strengthen the pipe protection, and optimize the pipe selection standard, so as to bring more economic benefits for companies.

The property of stainless steel includes: highly intensive, corrosion-resistant, life-long, maintenance-free, safe, clean, and beautiful. As a new material, thin- wall stainless steel tubing also gets some problems, which are:

1) Selection Problems

Due to the lack of market research, many natural gas companies will rely on their past experiences when choosing thin-thickness stainless steel pipe, which brings unreasonable decisions on construction material selection and buries a “bomb” on the project. For natural gas project, it covers a large construction area, and always includes a long construction route, which brings high requirements for construction materials. Besides, different geographical environments also have different requirements for the construction of pipes. Therefore, construction materials cannot always remain the same. Doing environmental survey thus becomes an important work while preparing for a construction project, which will help to select construction materials and make construction plan.

However, due to the limit construction time, many construction units will simplify the environmental survey, and the workers are not familiar with their construction environment, leading to the mistakes in the material selection. China has a vast territory, and there are great differences in the geographical environment. Therefore, we must have a comprehensive understanding of the environment before the project begins. Thin-thickness stainless steel pipe is an alloy material, and there are differences in its models. If there is no detailed investigation of the environment, it will be easy to make mistake in pipe selections.

2) Problems of Thin-thickness Stainless Steel Pipe in Indoor Gas Engineering Project

After thin-thickness stainless steel pipe being put into use, the overall appearance of the building will become beautiful. Meanwhile, the professional tools required during the installation also prevent the residents’ rebuilding. In practical application, it shows that there are a few corrosion spots of on the pipe wall, the reasons are as follows:

a) Quality Problem of Stainless Steel

For model 430 stainless steel pipe, it is primarily used for decorative purposes. It performs very well in dry indoor environment, but less effective in heat and corrosion resistance. As for model 304 stainless steel pipe, it contains nickel. It is always used in the highly polluted industrial areas or humid environment. It performs good in acid resistance, and is applied into food industry, surgical equipment and other fields. Currently, model 304 stainless steel pipe performs better in the gas engineering projects rather than model 430.

b) External Factors

Before buildings are put into use, they are cleaned with solvents. Oxalic acid will cause electrochemical reaction for stainless steel, resulting in corrosion of thin-thickness stainless steel pipes. Some experiments have shown that, after cleaning, oxalic acid still has strong influence for stainless steel pipe line even though it was clean a week ago. And this always occurs in the cities with heavy industry or humid, rainy areas.

c) Other Factors

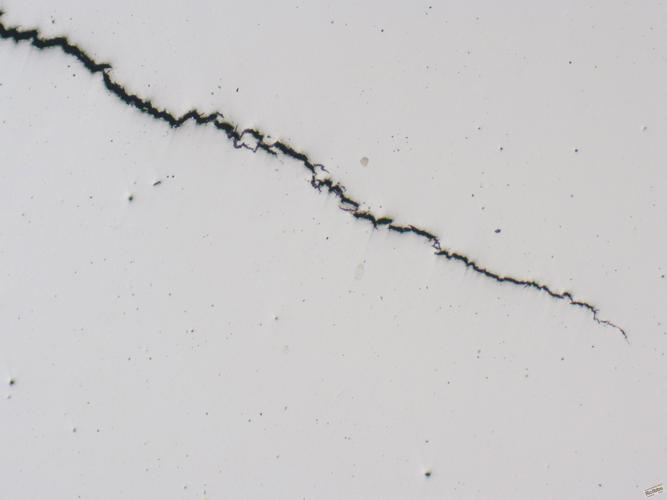

While storing, transporting or constructing, thin-thickness stainless steel pipes may be hit, leading to the dents, scratches and other situations of the pipe. It will make its anti-corrosion performance become weak. Or, if the pipe is mixed with impurities, it will also bring possible corrosion.

3) Thin Wall Stainless Steel Pipe Supplier

As a professional stainless steel pipe supplier in China, Kaysuns are ability to provide thin wall stainless steel seamless pipe for the projects, like 24″ * SCH10S, 16″ * SCH10S, 18″ * SCH10S, 20″ * SCH10S in seamless. You are welcome to contact us if you have any requirements.