Analysis Of The Characteristics Of Duplex 2205 Stainless Steel

The main alloying elements of duplex 2205 stainless steel are Cr, Ni, Mo and N, of which the Cr content is 22%. Cr and Mo are used to increase the ferrite content, while Ni and N are austenite stabilizing elements. Some steel types also contain elements such as Mn, Cu, and W.

Cr, Ni, and Mo can improve the corrosion resistance, and the performance of pitting and crack corrosion is particularly good in the environment containing chloride. N is an austenite-forming element that increases the pitting and crevice corrosion resistance of duplex stainless steels. Nitrogen can delay the precipitation of metal gaps and reduce the tendency to form σ phases in duplex stainless steels.

The mechanical properties of duplex stainless steel are related to the tempering temperature of the steel plate. The higher the tempering temperature, the lower the strength.

When the tempering temperature is 600 ℃, the yield strength is 400 MPa and the tensile strength is 650 MPa.

Figure 1 shows the metallurgical structure of duplex 2205 stainless steel (corrosive 30g K (OH) + 30g K3 Fe (CN) 6 + 100ml H2O). The metallurgical structure of duplex stainless steel consists of alpha ferrite (black) and gamma austenite. The body (white) is composed of two phases and has the characteristics of substantially equal volume fraction.

Therefore, duplex stainless steel has the dual characteristics of austenitic stainless steel and ferritic stainless steel. Compared with ferritic stainless steel, it has high toughness, low ductile-brittle transition temperature, significantly improved intergranular corrosion resistance and welding performance, while retaining the characteristics of high thermal conductivity, small expansion coefficient, and superplasticity of ferritic stainless steel; Compared with austenitic stainless steel, the yield strength and fatigue resistance are significantly improved, which is about twice that of austenitic stainless steel, and the resistance to intergranular corrosion, stress corrosion, and corrosion fatigue is significantly improved.

Nitrogen plays an important role in strengthening 2205 duplex stainless steel, but when the mass fraction of nitrogen exceeds 0.2%, the strength of austenite is greater than ferrite due to the interstitial solid solution strengthening of nitrogen. Increasing the content of ferrite will cause the impact toughness to decrease, and also cause the precipitation of nitrogen in ferrite, resulting in the formation of chromium nitride, because nitrogen has a lower solubility in ferrite than in austenite.

Cold treatment can reduce the impact toughness of 2205 duplex stainless steel and increase the ductile-brittle transition temperature. And the aging in the range of 280-350 ℃ will also lead to reduced toughness.

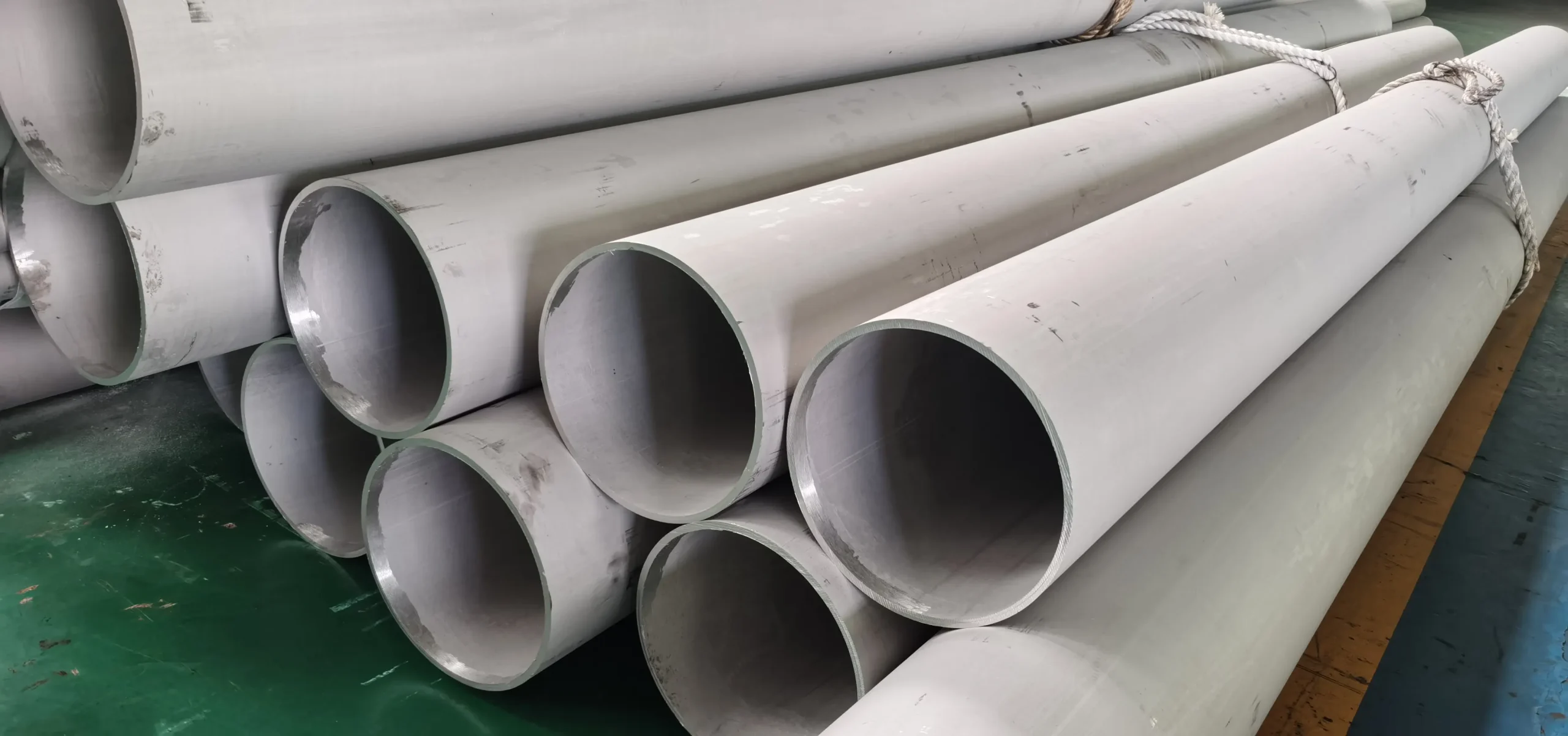

Duplex 2205 pipe is made of duplex 2205 steel, so these characteristics are also inherited.