Hastelloy B2 Alloy Overview

Hastelloy B2 alloy,which belongs to the Hastelloy alloy family , was developed mainly to prevent intergranular corrosion and knife edge corrosion of Hastelloy B alloy.

The main difference between this alloy and Hastelloy B alloy is the low carbon content and silicon content in the chemical composition, and the iron content has dropped from less than 6% to 2%.

Due to the changes in the content of carbon, silicon, and iron, although the matrix structure of Hastelloy B2 alloy is not different from that of Hastelloy B alloy, the precipitation phase on the alloy matrix or along the grain boundary is very different.

Corrosion Resistances

Total corrosion, the performance characteristics of B2 alloy against hydrochloric acid, sulfuric acid, phosphoric acid and other inorganic acids are basically the same as Hastelloy B alloy. The corrosion resistance is generally better than that of Hastelloy B alloy, especially after welding. In 20% boiling hydrochloric acid, even if the B2 alloy is deformed by 50% in cold working, it does not affect its corrosion resistance.

Intergranular corrosion, due to the low content of carbon, silicon and iron in Hastelloy B2 alloy, carbides and some intermetallic phases in sensitized steel are far less than Hastelloy B alloy, therefore, the resistance of this alloy to intergranular corrosion better.

Stress corrosion, the test shows that when the residual Fe≤2% and Cr≤1.0% in the Hastelloy B2 alloy is too low compared with the same alloy with proper control of the amount of iron and chromium. Better than the former.

Mechanical Properties of Hastelloy B2 Alloy

The plasticity of Hastelloy B2 alloy at medium temperature aging state decreases and deteriorates with time. This is related to the precipitation of β-phase which is hard and brittle in the middle temperature aging state.

Welding Performance

Hastelloy B2 alloy has good welding performance, and because of the low content of carbon, silicon and iron in this alloy, the resistance to intergranular corrosion and knife edge corrosion after welding is better than Hastelloy B.

When the amount of iron and chromium in the alloy is properly controlled, the plasticity, toughness, corrosion resistance and weldability of Hastelloy B2 alloy will be further improved.

Hastelloy B2 alloy generally does not require heat treatment after welding. This alloy is more suitable for welding equipment and components than Hastelloy B alloy.

Cold and hot processing and forming performance & heat treatment process

Its cold and hot processing and forming properties are basically similar to Hastelloy B alloy. However, when the amount of iron and chromium in B2 alloy is properly controlled, its workability, especially thermoformability, will be significantly improved.

Except for the special instructions, they need to be treated after solution treatment at 1066℃. Except those who control the amount of Fe+Cr in the alloy, it is generally not allowed to stay and use for a long period of time between 538~816℃

Applications

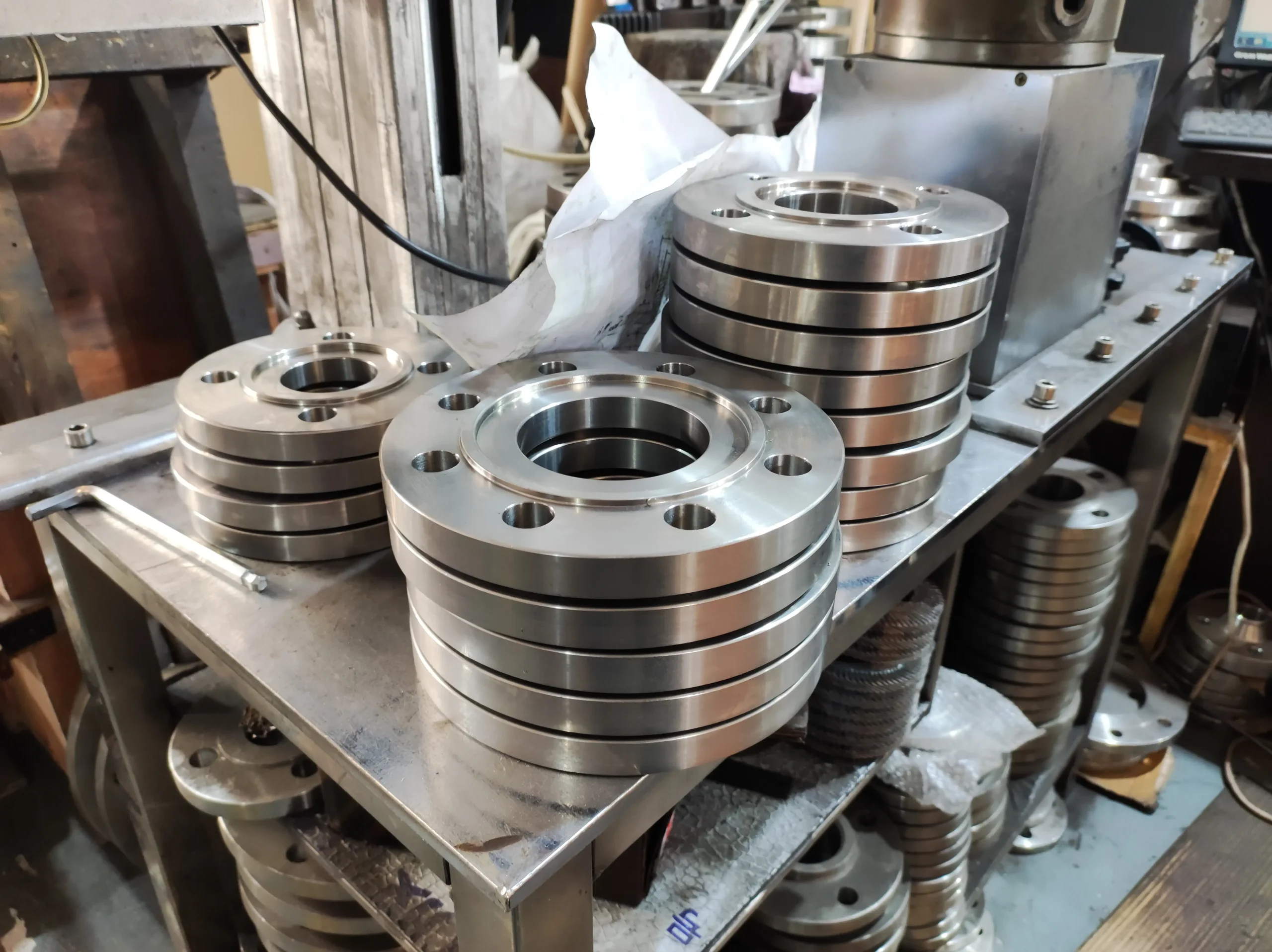

B2 alloy can produce plates, pipes, bars, wires, strips and forgings.

Mainly used in pipe and fittings, containers and their linings, reaction towers and linings, pumps and valves that are resistant to hydrochloric acid, sulfuric acid, phosphoric acid and formic acid.