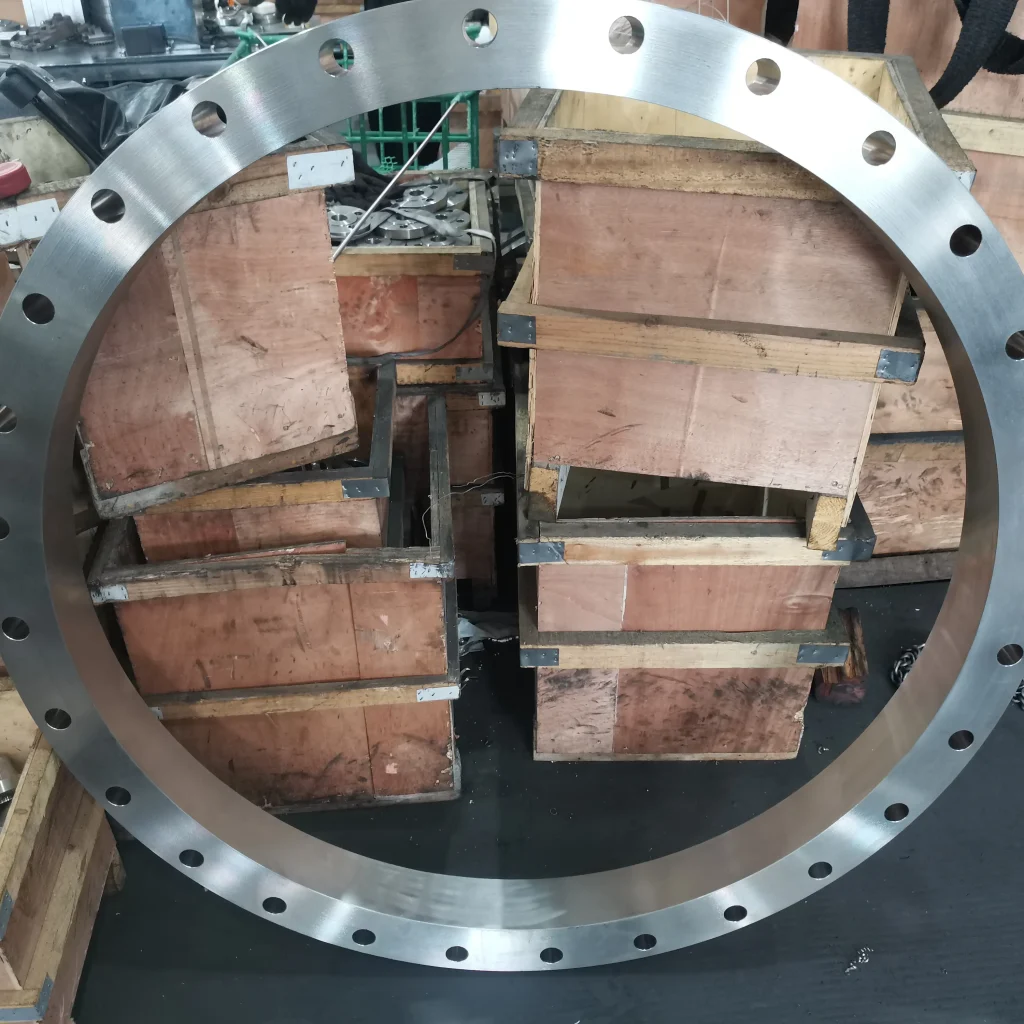

DIN FLANGE

Professional Chinese Supplier

We supply DIN flanges manufactured from materials including Stainless Steel,Nickel-based Alloy and other Alloy Steels.Other materials can be provided according to your requirements. Contact us for a FREE and FAST Quote!