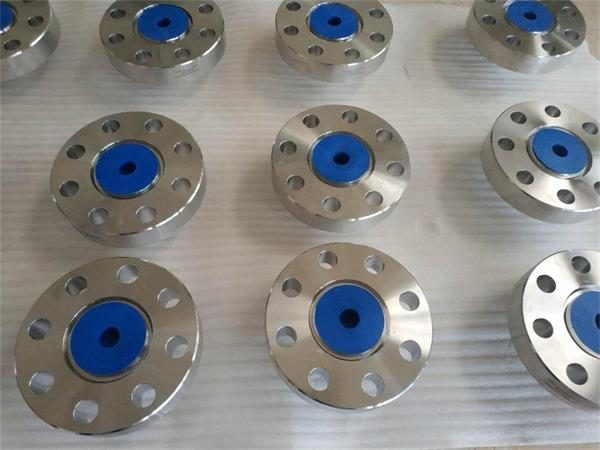

Manufacturing of flange products

Stainless Steel

ASTM A182 F304, F304L,F316, F316L, 316Ti, F317L, F321,F321H, F310H, F347H, N08904, F44 etc.

Duplex&Super Duplex

ASTM A/SA182 F51, F53, F55, F59, F60

Nickel-based Alloy

Hastelloy C22, C276, B3; Monel Alloy 400, K500; Inconel 600, 625, 601, 602; Incoloy 800, 800H/HT, 825, Alloy 20, NIkel 200/201 etc.

Titanium Alloys

ASTM SB381 F1, F2, F3, F5, F7, F9, F12 etc.

Aluminium Alloy

ASTM B247 GR 6061, GR.5083 etc.

Other Alloys

ASTM A105,A105N; St37.2, C22.8; ASTM A182 F11, F12, F22, F5, F91; ASTM A350 LF2, LF3; ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70 etc.

How We Handle Details Makes Us Different

The performance, durability, and service life of DBV industrial valves come from how we process and prepare each of our raw materials: properly, with great attention to detail.

RAW MATERIAL

Carefully selecting steel, we shape the materials into workpieces required for industrial valves.

1

FORGING

Metal materials are processed in our heat treatment furnace to improve their microstructure, ensuring the performance of our pump valves can meet our standard requirements.

2

HEAT TREATED

The precision machining process includes the use of precision machining equipment to ensure that all of our industrial valves have the expected quality and stable performance

3

MACHINING

Experienced employees carry out processing to ensure that the dimensions and shapes of all workpieces are accurate to the expected design range.

4

MARKING

Our CNC pentahedral machining center has made minor adjustments to the dimensions, design concepts, and shapes of industrial valve workpieces.

5

FINAL INSPECTION

We inspect the quality, size, and shape of each component. Ensure that each one meets international standards