What is ISO 9001 2015 ? It is a global standard that defines a robust Quality Management System (QMS). Understanding the certification is critical to ensure your reliable partners provide exceptional service and receive qualidade produtos.

What is ISO 9001:2015? A Global Standard for Quality!

ISO 9001:2015 is the latest version. It focuses on effective quality management to help organisations meet customer needs and ensure consistency in product delivery. The standard is not aimed at product quality per se. Instead, it provides guidance on the processes that create quality products. It provides a framework that organisations can use to improve their operations.

Key Principles of ISO 9001:2015

ISO 9001:2015 is built on several fundamental principles. These principles benefit both the certified company and its customers. They ensure better products like tubo de aço inoxidável e acessórios.

Organisations prioritise understanding customer needs. They strive to meet and exceed customer expectations. This means better products and services. For buyers, it means reliable Stainless Steel Pipe Fittings.

Strong leadership drives the quality management system. Leaders set clear goals. They create an environment for success. This commitment ensures that quality permeates the entire organisation. It ensures consistent product quality.

Everyone in the company contributes to quality. Employees have the ability and authority to participate in improving processes. This results in higher quality products.

Quality is managed through interrelated processes.” Inputs lead to outputs”, this systematic view increases efficiency. It ensures consistent product quality and helps to provide reliable tubos de aço inoxidável.

Continuous improvement is fundamental. Organisations identify opportunities for improvement. They proactively address non-conformities. This ensures that the quality management system continues to evolve. High product standards are maintained.

ISO 9001:2015 Requirements for Manufacturers

Implementing ISO 9001:2015 requires adherence to specific clauses. These ensure a comprehensive quality management system.

| Clause Focus | Descrição |

|---|---|

| Context of Org. | Internal/external issues |

| Leadership | Top management commitment |

| Planning | Risks, opportunities, objectives |

| Support | Resources, competence, communication |

| Operation | Product/service provision |

| Performance Eval. | Monitoring, measurement, analysis |

| Improvement | Nonconformity, corrective actions |

O que fazemos

Benefits for Buyers of Certified Products

| Benefit | Impact on Procurement |

|---|---|

| Consistent Quality | Predictable product standards |

| Reduced Risk | Fewer defects, less rework |

| Improved Efficiency | Smoother supplier interactions |

| Enhanced Trust | Reliable partnership foundation |

| Better Traceability | Clear product history, accountability |

| Global Acceptance | Widely recognized standard |

ISO 9001:2015 in Stainless Steel Pipe and Fittings

- Raw Material Control:

Suppliers must ensure raw material quality. They check stainless steel coils and billets. This prevents issues at the start. - Manufacturing Consistency:

Processes like welding, forming, and tratamento térmico are controlled. Standards ensure uniform pipe dimensions. This includes fitting angles and wall thicknesses. - Rigorous Testing:

Products undergo strict testing. This includes hydrostatic tests and material analysis. Inspections ensure adherence to specifications. - Documentation and Traceability:

Every batch is documented. From raw material to finished product. This allows full traceability. It ensures accountability. - Continuous Improvement:

Manufacturers regularly review processes. They seek ways to enhance quality. This leads to better conexões para tubos de aço inoxidável.

The Rigor of Achieving ISO 9001:2015 Certification

Companies first analyze their current processes. They identify gaps against the standard. This forms the basis for improvement.

Design a comprehensive quality management system. Including policies, procedures and work instructions. Every department is involved.

Putting the new quality management system into practice requires rigorous training of the staff.

The company conducts self-audits to check compliance and identify areas for further improvement.

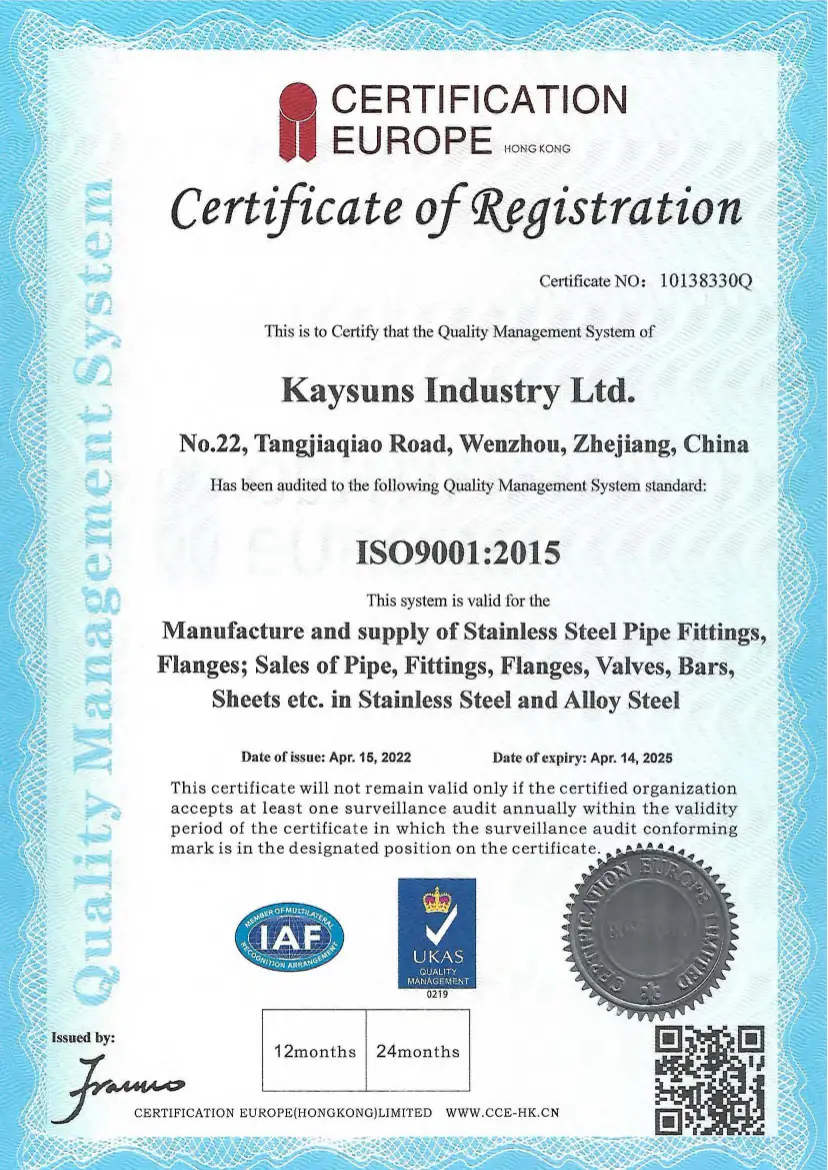

An independent third-party auditor reviews the quality management system to verify its effectiveness. A successful audit results in certification.

Certification requires a sustained effort. Surveillance audits are conducted annually. Recertification takes place every three years. Continuity of quality is ensured.

Talvez você também queira ler:

CE-PED : Acesso ao mercado da UE.

Qualidade garantida. ISO 9001 e CE-PED para aço inoxidável impecável!

Talvez você também queira ver Todos os certificados

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/