o 3-A sanitary standards for acessórios sanitários is a crucial guideline. For sanitary applications, it is especially important for fittings in environments where hygiene is critical. These standards ensure that your tubulações de aço inoxidável e conexões para tubos de aço inoxidável meet the highest sanitary benchmarks.

What Are 3-A Sanitary Standards? A Commitment To Purity!

3-A sanitary standards provide guidance for the design and manufacture of equipment used in the sanitary industry, including the dairy, food and pharmaceutical industries, with the aim of preventing contamination. These include the dairy, food and pharmaceutical industries, and are designed to prevent contamination. 3-A organisations are made up of industry experts who are responsible for developing these standards.

Why 3-A Sanitary Standards Matter for Your Business

The 3-A certified design eliminates the seam in the tubing itself, which greatly reduces the growth of bacteria. Ensuring your product remains pure.

Smooth surfaces and sloped design support better and more thorough cleaning. It supports the Clean-in-Place (CIP) process to save time and resources.

Your commitment to the 3-A standard builds trust and shows that you adhere to top hygiene practices. This gives end-users peace of mind about product safety.

Core 3-A Design Principles

| Principle | Descrição | Benefit for Sanitary Fittings |

|---|---|---|

| Cleanability | Easy to disassemble, inspect, clean | Effective CIP/SIP, reduced labor |

| Smooth Surfaces | Ra values specified, no imperfections | Prevents bacterial adhesion |

| Non-Product Contact Materials | Food-grade, non-toxic, non-absorbent | No leaching, maintains product purity |

| Drainability | No liquid retention, sloped design | Prevents microbial growth |

| No Product Traps | Eliminate crevices, dead ends | Prevents contaminant buildup |

| Material Durability | Corrosion-resistant, robust | Long lifespan, maintains integrity |

O que fazemos

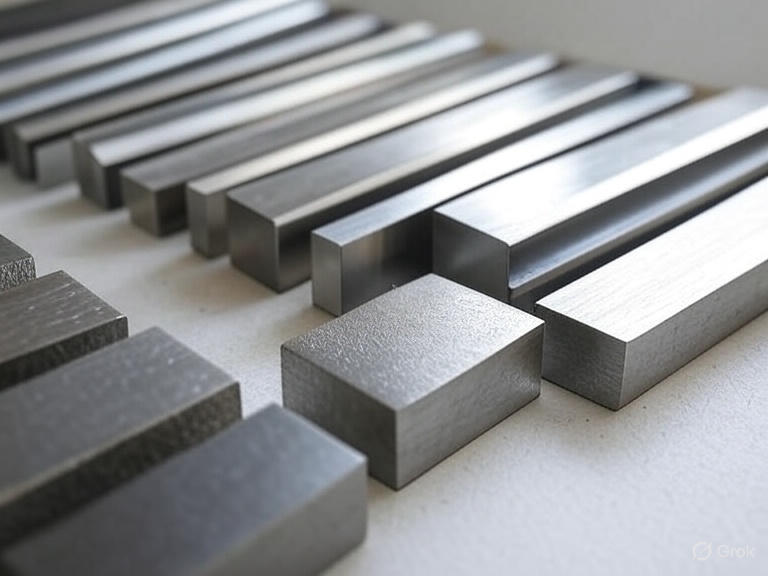

3-A Requirements for Stainless Steel Components

| Component / Aspect | 3-A Requirement | Importance for Hygiene |

|---|---|---|

| Stainless Steel Grade | 304L, 316L minimum | Corrosion resistance, cleanability |

| Acabamento da superfície | Typically Ra | ≤32μin |

| Welds | Smooth, flush, crevice-free internal welds | Eliminates traps for bacteria |

| Gaskets / Seals | Food-grade, non-absorbent, non-toxic | Prevents contamination |

| Joints / Connections | Quick-connect, self-aligning, drainable | Reduces leaks, simplifies cleaning |

| Radii | Minimum internal bend radii specified | Eliminates sharp corners, easy flow |

Common 3-A Certified Sanitary Fittings

- Sanitary Welded Elbows/Tee: With smooth internal welds, they ensure seamless flow transitions.

- Sanitary Clamped Tees/Cotovelos: They can be quickly disassembled using a clamping device. Facilitates frequent manual cleaning.

- Sanitary Unions: Provide hygienic, reusable connections. Facilitates system modification, easy disassembly and inspection.

- Sanitary quick couplings: Designed for quick, tool-less connection/disconnection, often used on hoses.

- Grampos Sanitários: Used to secure clamped fittings to ensure a tight, leak-proof seal.

- Sanitary Weld Reducers: Smoothly transition pipe sizes to maintain a sanitary welded connection.

Sourcing 3-A Certified Sanitary Fittings

Verify the official 3-A mark on your product to ensure compliance.

Request a 3-A authorisation certificate and obtain a material test report (MTR).

Trabalhar com manufacturers who specialise in hygiene products. They understand specific 3-A requirements and ensure proper manufacturing.

UMA Reputable supplier welcome audits. They will demonstrate their commitment to 3-A standards.

Ensure that accessories arrive in sanitary packaging. This prevents contamination during shipping.

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/