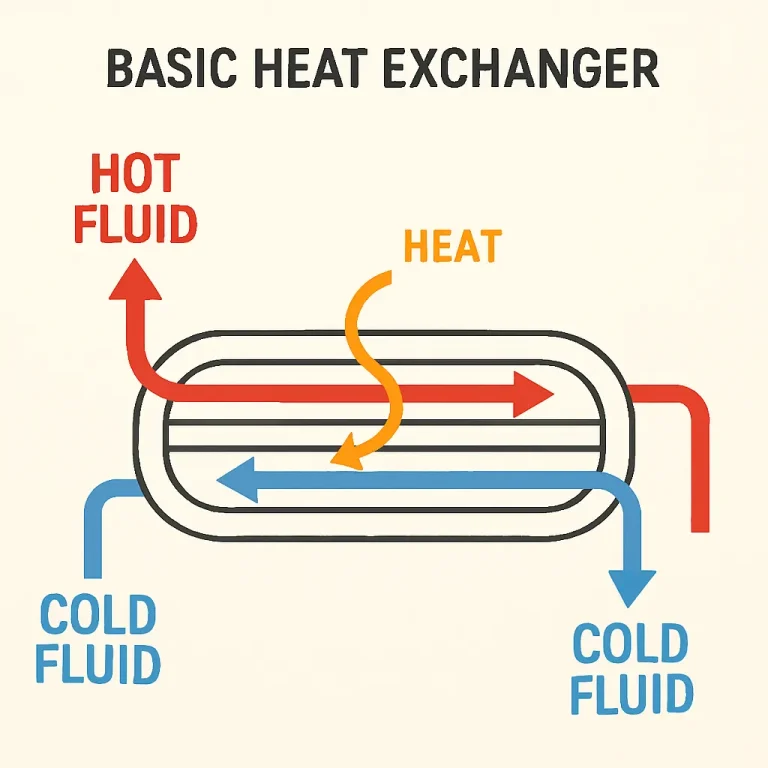

UMA trocador de calor em aço inoxidável é um dispositivo de transferência de calor altamente eficiente. Esses sistemas críticos são empregados para transferir energia térmica entre dois fluidos distintos. É fundamental que esses dois fluidos nunca sofram mistura física.

O equipamento é conhecido por sua durabilidade e resistência à corrosão, o que o torna uma excelente opção para ambientes adversos.

O papel de um trocador de calor de aço inoxidável

Um trocador de calor é fundamental para o gerenciamento térmico. Ele transfere o calor de um fluido mais quente para um mais frio. Esse processo é necessário para aquecimento, resfriamento ou recuperação de energia. A construção em aço inoxidável garante a integridade. Ela permite que a troca de calor ocorra de forma confiável sob pressão. O alto desempenho é mantido mesmo com fluidos de processo corrosivos.

Princípio de funcionamento

- Separação: Um fluido flui de um lado da barreira. O segundo fluido flui do lado oposto. Isso mantém os dois meios fisicamente separados.

- Condução: O calor se move através da parede sólida de aço inoxidável. A energia térmica viaja do fluido mais quente para o mais frio. O aço inoxidável fornece a área de transferência térmica necessária.

- Tipos de fluxo: Os fluidos se movem de diferentes maneiras para maximizar a transferência.Fluxo contracorrente é o projeto mais eficiente. Os fluidos entram no trocador pelas extremidades opostas.

O que fazemos

- Placa

- Folha

- Forjados

- Barra redonda

- Mesa

- Tubos

- Conexões

- Personalizado

Entre em contato conosco para obter mais informações

Características

- Resistência à corrosão: A principal vantagem do aço inoxidável está em sua resistência à corrosão, que pode suportar produtos químicos altamente corrosivos. Graus como o 316 e o aço duplex resistem à erosão ácida.

- Alta resistência mecânicaEste material resiste à deformação sob alta pressão, mantendo a integridade estrutural.

- Superfície higiênica: Sua superfície lisa e não porosa facilita a limpeza, inibe o crescimento bacteriano e evita a aderência de sujeira, tornando-o essencial para aplicações sanitárias.

- DurabilidadeO aço inoxidável apresenta resistência à expansão térmica e à fadiga, garantindo uma vida útil prolongada e reduzindo a necessidade de substituições frequentes.

Vantagens

- Compatibilidade química: O aço inoxidável previne a corrosão química das superfícies metálicas.

- Longa vida útil: A camada de óxido passivada protege o material contra a ferrugem.

- Flexibilidade de design: O aço inoxidável pode ser aplicado a várias formas estruturais, incluindo trocadores de calor de casco e tubo ou de placa.

- Resistência a altas temperaturas: A maioria dos tipos de aço inoxidável mantém sua resistência em ambientes com altas temperaturas.

Desvantagens

- Condutividade térmica: O aço inoxidável conduz o calor mais lentamente do que outros metais.

- Custo inicial mais alto: Os equipamentos de aço inoxidável têm um custo inicial mais alto do que os de aço carbono.

- Sensibilidade à soldagem: Alguns aços inoxidáveis apresentam sensibilidade ao calor da soldagem, o que pode exigir um tratamento pós-soldagem adequado.

- Tendência à formação de incrustações: O aço inoxidável pode acumular incrustações de água, exigindo limpeza e manutenção periódicas.

Classes comuns de trocadores de calor em aço inoxidável

Esta tabela detalha os tipos comuns de aço inoxidável utilizados para tubulação do trocador de calor. A escolha do material depende da corrosividade do fluido.

| Grau | Principais recursos | Melhor para |

|---|---|---|

| Aço 304 Aço 304L | Uso geral | HVAC, baixa pressão |

| Aço 316 Aço 316L | Resistência a cloretos | Química, processamento de alimentos |

| Duplex 2205 | Alta resistência | Petróleo e gás, alta pressão |

| Aço 904L | Excelente resistência aos ácidos | Aplicações do ácido sulfúrico |

Tipos de trocadores de calor em aço inoxidável

| Modelo | Foco no design | Aplicativo principal |

|---|---|---|

| Casca e tubo | Alta pressão | Usinas de energia, refinarias |

| Placa | Alta eficiência | Alimentos, bebidas, climatização |

| Espiral | Fluidos viscosos | Processamento de lama |

Aplicações do trocador de calor em aço inoxidável

- Alimentos e bebidas: Os trocadores são utilizados para pasteurização e resfriamento. A higiene é imprescindível neste setor. A superfície lisa em aço inoxidável evita a contaminação.

- Processamento químico: As unidades resistem a ácidos e produtos químicos altamente corrosivos. Tubo enrolado do permutador de calor O design é frequentemente utilizado. Maximiza a área de superfície num espaço reduzido.

- Indústria farmacêutica: Os sistemas de alta pureza dependem de um controle preciso da temperatura. O aço inoxidável garante que não ocorra contaminação. Ele atende a rigorosos requisitos regulamentares.

- Geração de energia: São utilizados em condensadores e sistemas de recuperação de calor. Os sistemas de trocadores de calor em aço inoxidável suportam altas pressões e altas temperaturas. São essenciais para a eficiência do sistema.

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/