Post-weld treatment restores material properties and improves durability. Welding is key to pipework joining, but it also carries hidden dangers, including the risk of corrosion and residual stresses. Post-weld treatment addresses these issues and is a key process for tubulação de aço inoxidável e acessórios.

What is Post-Weld Treatment? Enhancing Welded Components!

Post Weld Treatment (PWT) is designed to improve the performance of welded joints and is performed after welding. It can eliminate stress, restore resistência à corrosão and improve mechanical strength. It ensures reliable performance of welded parts and is particularly important for stainless steel pipes and fittings.

Why Post-Weld Treatment is Crucial

Welding creates internal stresses that can cause distortion and possibly stress corrosion cracking, and PWT reduces these stresses to improve stability.

Welding heat sensitises the stainless steel and depletes chromium near grain boundaries. PWT re-dissolves the carbides, thus restoring the passive layer. Prevents corrosão intergranular.

Certain embossing processes can improve toughness. They refine the microstructure, which improves the overall strength and also increases ductility. This makes the part stronger.

Welding creates oxides and discolouration, and PWT removes these contaminants, which are critical for hygienic applications.

PWT is required by many industry codes for critical pressure-containing parts. Compliance ensures safe operations. It also avoids regulatory penalties.

Key Post-Weld Treatment Methods

| Method | Finalidade | Aplicação |

|---|---|---|

| Recozimento de solução | Restore Cr, relieve stress | Sensitized materials |

| Stabilizing Annealing | Prevent carboneto formação | Stabilized grades |

| Stress Relieving | Reduce residual stress | Distortion prevention |

| Pickling | Remove oxides, scale | Surface cleaning |

| Passivation | Restore passive layer | Resistência à corrosão |

| Electropolishing | Smooth, clean surface | Hygienic, aesthetic |

O que fazemos

Welding's Effects on Stainless Steel

| Effect | Descrição | Risk Created |

|---|---|---|

| Heat-Affected Zone (HAZ) | Area near weld, changed by heat | Reduced properties, sensitization |

| Chromium Carbide Formation | Carbon combines with cromo | Corrosão intergranular |

| Residual Stresses | Internal forces after cooling | Distortion, SCC |

| Oxidation / Heat Tint | Surface discoloration, oxide layers | Pitting, crevice corrosion |

| Microstructural Changes | Grain growth, phase transformations | Reduced strength, toughness |

Post-Weld Treatment for Stainless Steel Pipe and Fittings

- Corrosão intergranular: Solid solution annealing is usually used, which can re-dissolve harmful carbides. This restores corrosion resistance. Mainly used for 304 and 316 grades.

- Stress Relief: Stress relieving heat treatment reduces internal stresses, prevents distortion and reduces the risk of rachaduras por corrosão sob tensão.

- Surface Integrity: Acid washing removes heat tint and scale. Passivation restores the passive layer. Electropolishing creates a smooth, hygienic surface. This prevents localised corrosion.

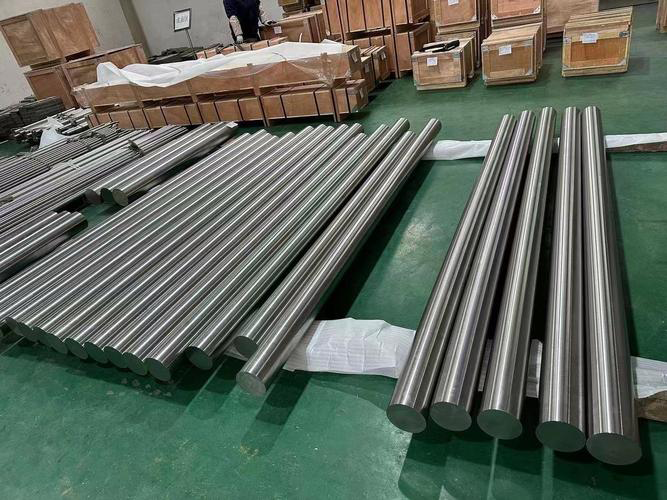

- For Complex Components: Large or complex tube shafts can benefit from PWT to ensure overall system stability. It guarantees consistent material properties.

Sourcing Reliable Components

Escolha um fabricante que tem ampla experiência com aço inoxidável e que entende suas propriedades exclusivas. Isso garante ótimos resultados de moldagem.

Procure recursos de ferramental de última geração, pois o ferramental de precisão é essencial e pode afetar a qualidade e a consistência das peças.

Garantir o rigor qualidade verificações estão em vigor, incluindo verificações dimensionais, etc. Verificação da integridade do material e relatórios de testes de materiais também são fundamentais.

Trabalhar com fabricantes de renome que oferecem produtos confiáveis de aço inoxidável e têm certificações(por exemplo ISO 9001 e CE-PED).

Confirme se o fabricante pode atender aos seus requisitos de volume de produção. Ele deve lidar tanto com a prototipagem quanto com a produção em volume.

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/