Nimonic 75 é uma solução confiável para temperaturas extremas. A resistência ao calor desta liga de alto desempenho é muito superior à dos aços inoxidáveis padrão. Suas propriedades únicas são essenciais para a durabilidade a longo prazo. Escolher o Nimonic 75 garante que suas aplicações críticas tubos de aço inoxidável e conexões para tubos de aço inoxidável manter sua força e funcionalidade.

Nimonic 75 | UNS N06075

Nimonic 75 é um liga à base de níquel pertencente ao grupo Liga Nimônica, que contém cerca de 201 TP4T cromo e, portanto, possui excelente resistência à oxidação. Possui boas propriedades mecânicas em altas temperaturas.

Principais pontos fortes do Nimonic 75

O Nimonic 75 é resistente à oxidação e pode suportar temperaturas de operação contínuas de até 980 °C (1795 °F).

Mantém a resistência em temperaturas elevadas para um desempenho confiável. Não foi projetado para resistir a deformação por fluência. No entanto, apresenta boa integridade mecânica em muitas aplicações.

O Nimonic 75 é fácil de moldar, fácil de soldar e adapta-se bem a fabricações complexas.

Mantém suas propriedades quando submetido ao calor e não perde resistência rapidamente, tornando-o ideal para aplicações em altas temperaturas.

Composição química

| Elemento | Ni | Cr | Fe | C | Ti | Cu | Mn | Si |

|---|---|---|---|---|---|---|---|---|

| Conteúdo (wt%) | Equilíbrio | 18.0-21.0 | 5,0 Máximo | 0.08-0.15 | 0.20-0.60 | 0,5 Máximo | 1,0 Máximo | 1,0 Máximo |

Propriedades mecânicas

| Propriedade | Resistência à tracção | Resistência ao escoamento (0,2% Offset) | Alongamento | Dureza | Densidade | Faixa de fusão |

|---|---|---|---|---|---|---|

| Valor (típico) | ≥690MPa(100ksi) | ≥275 MPa (40 ksi) | ≥30 | 200 Máximo | 8,26 g/cm³ | 1370−1420 ℃ |

Nimonic 75 em sistemas de tubulação de alta temperatura

- Tubos de chama: Podem suportar altas temperaturas e podem ser usados para tubos de chama.

- Sistemas de escape: Podem lidar com fluxos de gases quentes, resistem à oxidação e à corrosão e podem ser usados em coletores de escape.

- Tubos e foles: Esses materiais podem suportar ciclos térmicos e são transformados em tubos para altas temperaturas e foles de expansão.

- Componentes do forno: Resistem a altas temperaturas sustentadas e evitam a formação de incrustações nos revestimentos e proteções do forno.

- Sistemas de tubulação: Podem ser usados para conexões críticas de aço inoxidável onde é necessária resistência extrema ao calor.

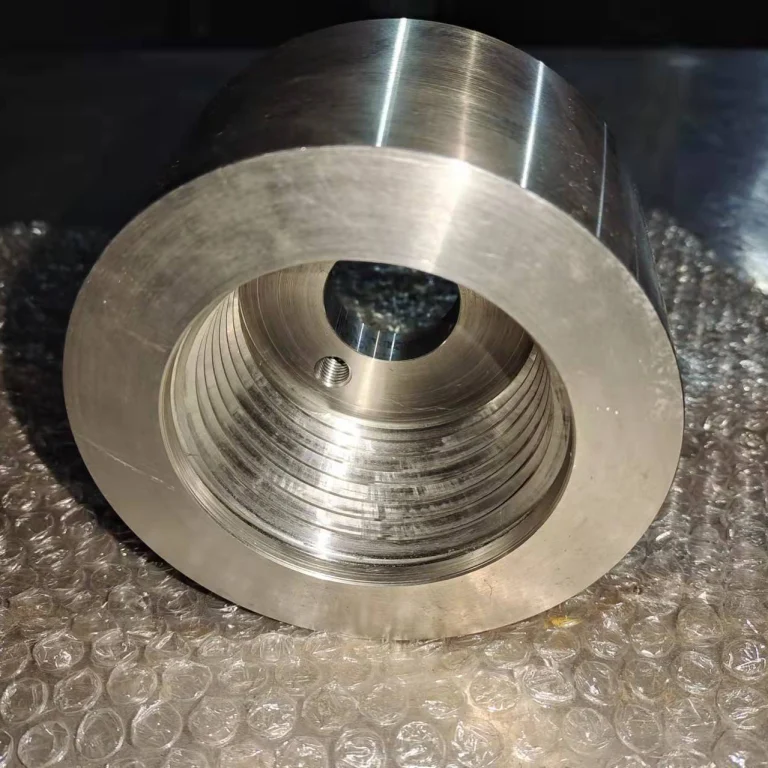

Fornecimento e fabricação de Nimonic 75

Um completo Relatório de teste de material (MTR) é necessário. Ele verifica a composição precisa da liga e garante seu desempenho.

Trabalhar com fornecedores especializados de tubos e conexões de aço inoxidável. Eles conhecem essas ligas de aço e podem garantir a fabricação e o controle de qualidade adequados, e são ISO 9001 e CE-PED certificado.

É difícil de usinar e requer ferramentas especiais. Técnicas específicas de soldagem são essenciais para garantir a integridade da solda.

Ele é caro, portanto, é importante avaliar se o produto tem uma vida útil mais longa. Isso pode justificar seu custo inicial mais alto.

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/