Over time, degradation of stainless steel materials occurs. However, piping systems transport vital fluids, which can lead to leaks and failures. Understanding these processes then is vital and ensures that your tubos de aço inoxidável e conexões para tubos de aço inoxidável são feitos para durar.

What Is Degradation of Stainless Steel Materials? A Constant Battle!

Degradation of stainless steel materials means that their properties deteriorate over time. This happens due to environmental interactions. Corrosion is the primary cause, as is mechanical stress. Understanding these mechanisms helps prevent failure.

Key Forms of Degradation of stainless steel materials

Corrosão intergranular erodes the grain boundaries. It occurs after sensitisation (cromo depletion). Welding is a common cause, weakening the material from within.

SCC is a combination of tensile stress and a ambiente corrosivo. Cracks can expand rapidly, leading to sudden failure. Chlorides are a common culprit.

Includes erosion of materials by fluid flow, but also includes chemical attack. This is exacerbated by high velocity fluids, affecting dobras and areas of turbulence.

Repetitive stress cycling leads to fatigue, where micro-cracks form and expand, eventually leading to fracture. Common in vibrating piping systems.

Factors & Their Impact on Stainless Steel

| Fator | Descrição | Risk to Pipe/Fittings |

|---|---|---|

| Corrosive Environments | Ácidos, cloretos, compostos de enxofre | Pitting, general corrosion |

| High Temperature | Elevated operating temperatures | Oxidation, sensitization, creep |

| Estresse mecânico | Pressure, vibration, external loads | SCC, fatigue, deformation |

| Surface Condition | Roughness, contamination, welds | Localized corrosion, pitting |

| Material Defects | Inclusions, improper heat treatment | Reduced resistance, premature failure |

| Fluid Velocity | High flow rates | Erosion-corrosion |

O que fazemos

Prevention Strategies for Stainless Steel

| Estratégia | Ação | Benefício para tubos e conexões |

|---|---|---|

| Grade Selection | Choose suitable stainless steel alloy | Resist specific environments |

| Proper Design | Avoid crevices, stagnation, stress points | Reduce localized attack |

| Acabamento da superfície | Polish, electropolish | Enhance corrosion resistance |

| Tratamento pós-soldagem | Clean, passivate, anneal welds | Prevent corrosão pós-soldagem |

| Revestimentos de proteção | Apply specialized barriers | Add extra defense |

| Monitoring | Regular inspection, non-destructive tests | Detect early degradation |

Impact of Degradation of stainless steel materials

- Operational faults: Leakage due to ageing pipes. This can lead to unplanned downtime. Production losses can be substantial.

- Safety hazards: Leaking hazardous liquids pose a danger and damage the environment.

- Increased Costs: Expensive repairs, replacement parts add to capital expenditure and increase operating costs.

- Shorter life: Equipment deteriorates faster, reducing its useful life. Hence the need for early replacement.

- Compliance issues: Failures can lead to non-compliance with regulations, which can result in fines and damage the company’s reputation.

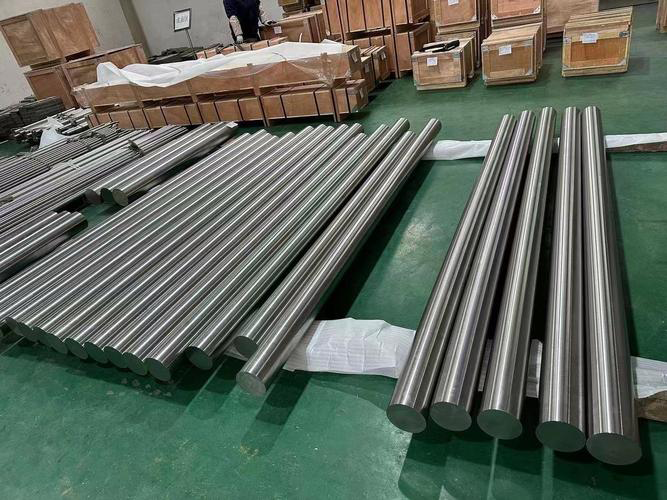

Sourcing Reliable Components

Escolha um fabricante que tem ampla experiência com aço inoxidável e que entende suas propriedades exclusivas. Isso garante ótimos resultados de moldagem.

Procure recursos de ferramental de última geração, pois o ferramental de precisão é essencial e pode afetar a qualidade e a consistência das peças.

Garantir o rigor qualidade verificações estão em vigor, incluindo verificações dimensionais, etc. Verificação da integridade do material e relatórios de testes de materiais também são fundamentais.

Trabalhar com fabricantes de renome que oferecem produtos confiáveis de aço inoxidável e têm certificações(por exemplo ISO 9001 e CE-PED).

Confirme se o fabricante pode atender aos seus requisitos de volume de produção. Ele deve lidar tanto com a prototipagem quanto com a produção em volume.

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/