Laminação a frio is a critical finishing process for metal manufacturing. It plays an essential role in producing high-quality tubos de aço inoxidável e conexões para tubos de aço inoxidável. This method refines material previously shaped by hot rolling. It creates products with superior surface quality and dimensional accuracy.

Stainless Steel Cold Rolling Process

Cold Rolling is a metalworking process. It happens below the steel’s recrystallization temperature. The material is passed between two rollers. This rolling reduces the thickness of the metal. The process significantly improves acabamento da superfície and dimensional tolerance. It hardens the material through work hardening.

O que fazemos

- Placa

- Folha

- Forjados

- Barra redonda

- Mesa

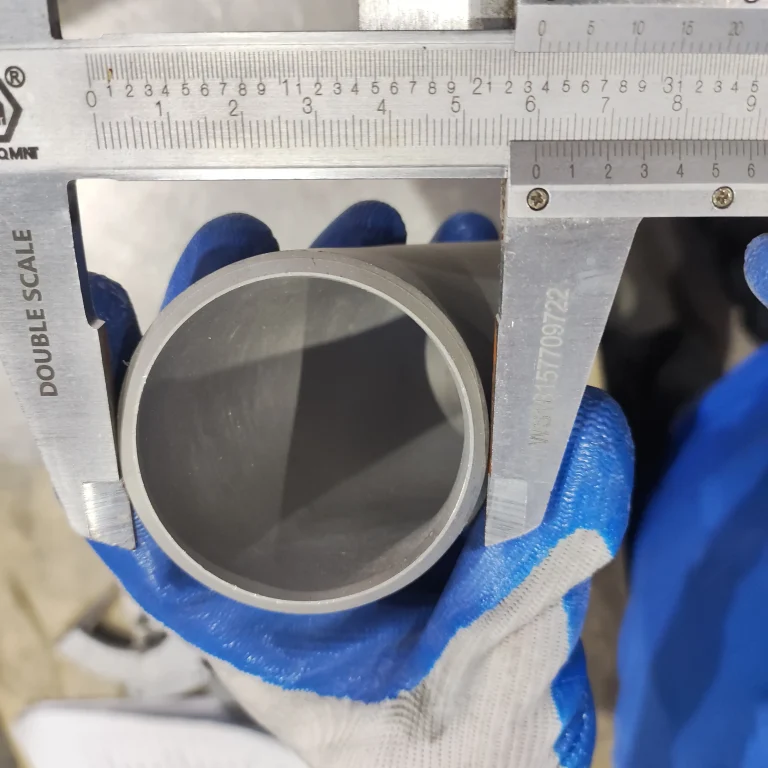

- Tubos

- Conexões

- Personalizado

Entre em contato conosco para obter mais informações

Key Advantages of Cold Rolling

Passing the metal through precise rolls smoothes the surface. This creates a clean, bright finish.

Precise roll control ensures uniform thickness. This process achieves very tight dimensional tolerances.

The process hardens the metal structure. This increases both tensile and yield strength. Material strength is significantly improved without altering its chemistry.

Rolling occurs at ambient temperature. This prevents surface oxidation or scale formation. The material retains a clean, bright appearance throughout.

Key Disadvantages of Cold Rolling

The process requires powerful mills and specialized lubrication. Material must be annealed between major reductions. This extra complexity increases the overall production expense.

Only small reductions in thickness are possible per pass. Attempting too much reduction can cause the material to crack. This often means multiple passes are necessary.

The quenching process enhances material strength but reduces its toughness. The material’s ductility consequently diminishes, which may necessitate a final annealing treatment.

Significant force is needed to deform cold metal. This subjects the equipment to higher stress. It limits the size of material that can be finished this way.

Comparing Hot Rolling and Cold Rolling

| Process | Temperatura | Superfície | Força |

|---|---|---|---|

| Hot Rolling | Alta | Rough | Médio |

| Laminação a frio | Ambient | Smooth | Alta |

Common Cold Rolled Grades and Products

| Grau | Principais recursos | Aplicações |

|---|---|---|

| 304/304L | Versatile, common | Welded pipe, Sheet components |

| 316/316L | Chloride resistance | Sanitary tubing, Flange shims |

| 430 | Magnético | Decorative trim, Pipe covers |

| Duplex 2205 | Alta resistência | Pressure vessel shells, Welded pipes |

Cold Rolling Process Equipment

| Equipment | Finalidade | Usage |

|---|---|---|

| Laminadora | Holds components | Applies pressure |

| Work Rolls | Reduce thickness | Shape material |

| Tension Reel | Holds material | Controls speed |

| Cooling System | Regulate temperature | Prevents overheating |

Preparation Before Cold Rolling

- First,the hot-rolled material must be thoroughly cleaned.Scale and surface impurities are removed via pickling.

- Next, the material may be annealed.This pre-annealing softens the metal, allows for easier deformation during the rolling process.

The Steps of Cold Rolling

- The starting material is threaded into the mill. Tension reels hold the material taut.

- The material passes between the work rolls. The rolls gradually reduce the material’s thickness. This process is repeated until the final gauge is reached. The finish is controlled by the roll surface.

Stainless Steel Cold Rolled Products

Cold Rolling is essential for high-quality finished products. Stainless steel pipes often begin as cold-rolled strip. This strip is welded into pipe or tubing. Stainless steel pipe fittings like cotovelos e camisetas can be hydroformed from cold-rolled sheet. The process is vital for the creation of precision sanitary tubing.

Ensuring Cold Rolling Quality

Maintaining quality requires strict control. Tension and speed must be consistent throughout the process. Online gauge monitoring ensures dimensional stability. After rolling, material often undergoes further treatment. This ensures the final product meets required specifications.

Post-Rolling Treatment

Cold-rolled material requires final processing. The work hardening must be relieved. Annealing is performed to restore ductility. Final processing often includes passivation. Passivation improves the material’s surface corrosion resistance. This prepares the final stainless steel pipe for its intended use.

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/