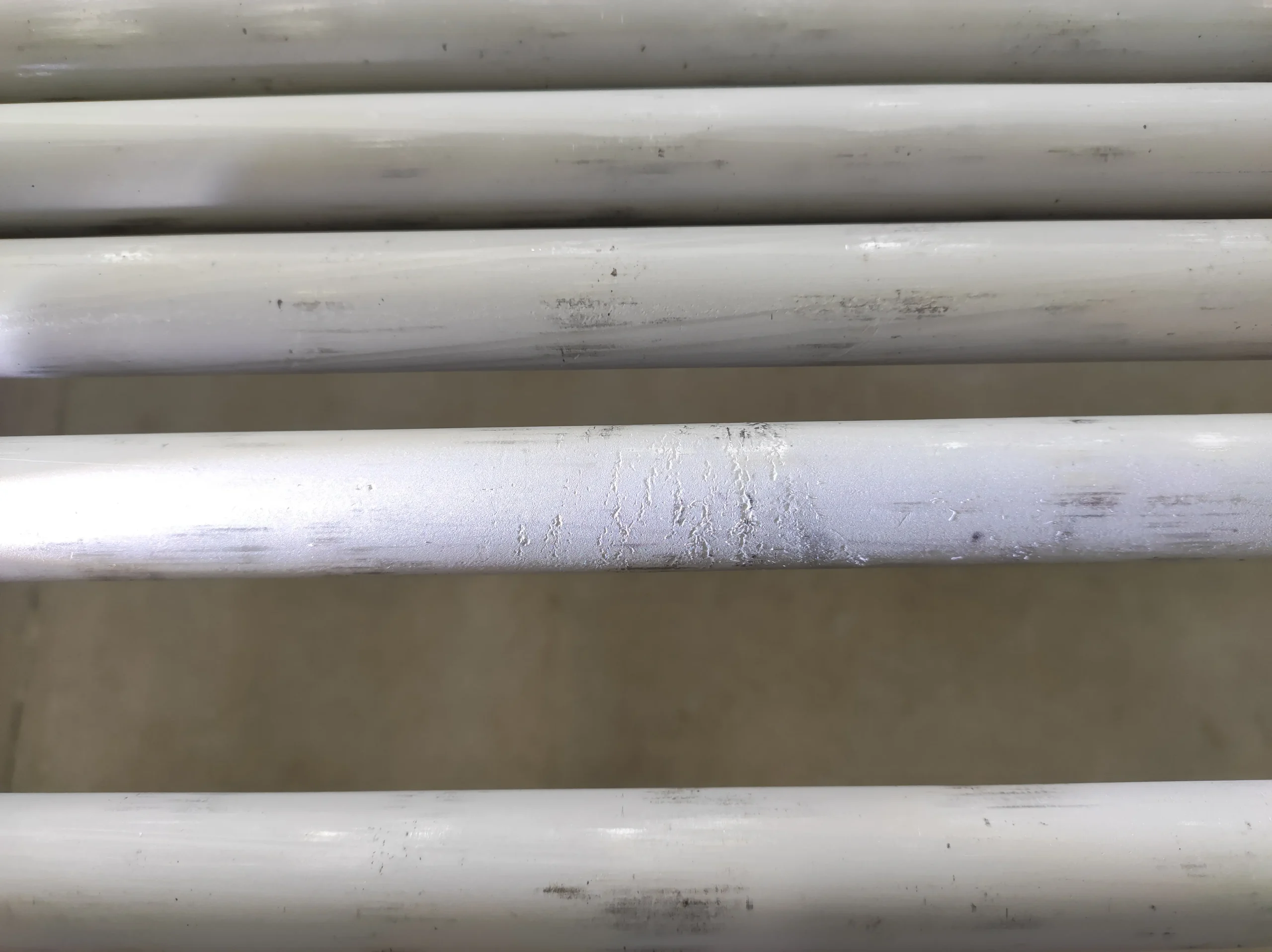

Incoloy 926 é um versátil liga de níquel-ferro-cromo-molibdênio que oferece excepcional resistência à corrosão em uma ampla gama de ambientes adversos. Este liga super austenítica oferece uma solução superior, destacando-se principalmente em aplicações em que o padrão tubos de aço inoxidável e conexões para tubos de aço inoxidável pode falhar.

O que é a liga Incoloy 926 | UNS N08926

O Incoloy 926 é uma liga especializada, uma variante do Incoloy 825 Ele apresenta uma maior teor de molibdênio e a adição de nitrogênio que aumentam significativamente sua resistência a corrosão por pite e corrosão em fendas. A composição exclusiva da liga faz dela o material preferido para ambientes que envolvem meios altamente corrosivos.

Principais desempenhos do Incoloy 926

Essa liga resiste a uma ampla gama de elementos corrosivos, inclusive cloretos e substâncias ácidas. Seu alto teor de molibdênio evita efetivamente a corrosão por pite, garantindo um desempenho confiável em ambientes marinhos e químicos.

O Incoloy 926 mantém as propriedades mecânicas em temperaturas elevadas. Sua excelente resistência garante a integridade estrutural em tubulações e conexões, tornando-o uma opção confiável para aplicações exigentes.

A composição da liga neutraliza efetivamente Rachadura por corrosão sob tensão-Um problema comum em muitos aços inoxidáveis, particularmente pronunciado em ambientes ricos em cloreto. Sua resistência a SCC aumenta significativamente a segurança do sistema.

O Incoloy 926 apresenta excelente soldabilidade e acomoda diversos processos de conformação. Essas propriedades facilitam a fabricação eficiente de tubulações e conexões, reduzindo substancialmente o tempo de instalação e os custos de mão de obra.

Composição química

| Elemento | Ni | Cr | Mo | Fe | Cu | Mn | Si | C | P | S | N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Conteúdo (wt%) | 24.0 – 26.0 | 19.0 – 21.0 | 6.0 – 7.0 | Bal. | 0.5 – 1.5 | ≤1.0 | ≤0.5 | ≤0.02 | ≤0.03 | ≤0.01 | 0.15 – 0.25 |

Propriedades mecânicas

| Propriedade | Resistência à tracção | Resistência ao escoamento (0,2% Offset) | Alongamento | Dureza | Densidade |

|---|---|---|---|---|---|

| Valor (típico) | ≥650MPa (94ksi) | ≥290MPa (42ksi) | ≥30 | ≤100 | 8,13g/cm³ |

Incoloy 926 em tubos e conexões

- Sistemas de tubulação: o Incoloy 926 mantém o desempenho em ambientes químicos altamente corrosivos em ambientes marítimos, lidando facilmente com condições de alta pressão e alta temperatura.

- Trocadores de calor: essa liga é a escolha ideal para tubos de trocadores de calor, suportando fluidos altamente corrosivos e resistindo à corrosão induzida por cloreto para garantir uma operação eficiente e segura do equipamento.

- Engenharia marítima e offshore: a excepcional resistência do Incoloy 926 à corrosão por pite e em frestas o torna particularmente adequado para sistemas de água do mar, garantindo a confiabilidade de longo prazo de tubulações e conexões.

- Processamento químico: o Incoloy 926 resiste a produtos químicos corrosivos, como o ácido sulfúrico, e mantém a integridade estrutural, evitando efetivamente vazamentos e perdas dispendiosas de tempo de inatividade.

Fornecimento e fabricação da liga Incoloy 825

Sempre solicite um Relatório de teste de material (MTR). Esse documento confirma a composição química e as propriedades mecânicas do material. O MTR garante a autenticidade e a confiabilidade do lote específico de aço-liga que você recebe e verifica sua conformidade com as especificações exigidas.

Selecione um Fornecedor profissional de tubos e conexões de aço inoxidável. Escolha de fornecedores certificados para ISO 9001 e CE-PED garante tranquilidade. Certificação ISO 9001 demonstra compromisso com os sistemas de gerenciamento de qualidade, enquanto Certificação CE-PED verifica a conformidade com os padrões de segurança do mercado europeu para equipamentos de pressão.

Essa liga requer Técnicas específicas de soldagem e fabricação. O alto teor de molibdênio pode causar problemas se for manuseado de forma incorreta, o que torna fundamental a padronização dos procedimentos. Certifique-se de que sua equipe domine os métodos de manuseio adequados e que os soldadores usem materiais e técnicas de enchimento compatíveis para evitar riscos como rachaduras a quente ou redução da resistência à corrosão.

Embora a liga Incoloy 926 tenha um custo inicial mais alto, sua vida útil excede em muito a das ligas padrão. A durabilidade excepcional reduz significativamente as despesas com manutenção e reparos de longo prazo, além de evitar falhas inesperadas no sistema. As economias substanciais decorrentes da vida útil prolongada proporcionam um alto retorno sobre o investimento inicial no Incoloy 926.

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/