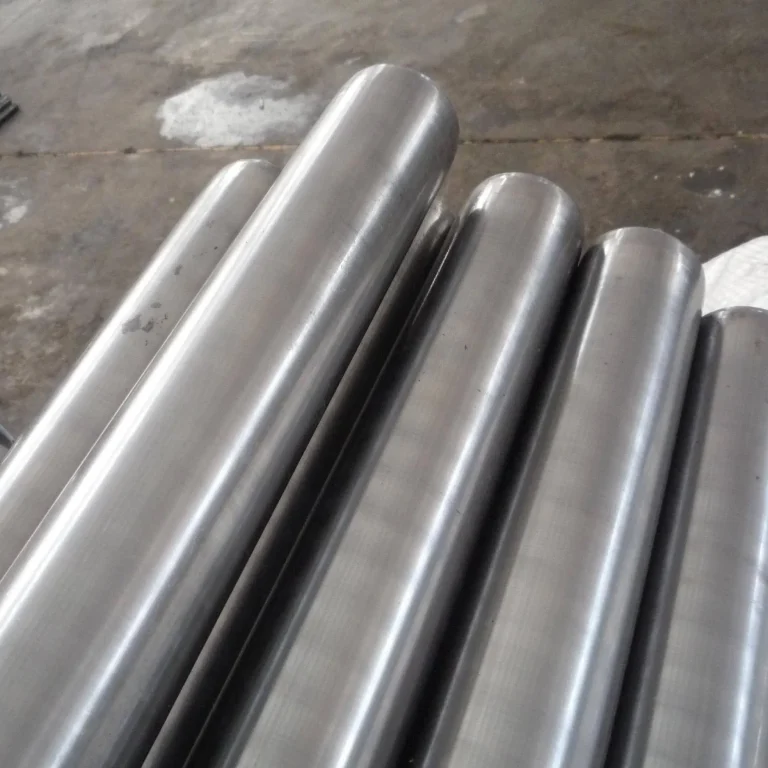

Sensibilização de aço inoxidável é uma questão crítica. Trata-se de uma alteração metalúrgica. Ela pode comprometer seriamente a integridade de um material. Também é conhecida como "deterioração da solda". Isso acontece com tubos de aço inoxidável e conexões para tubos de aço inoxidável. Entendê-lo é fundamental. Ele evita falhas inesperadas.

Sensibilização do aço inoxidável: uma ameaça oculta

O aço inoxidável sofre sensibilização quando aquecido. Esse fenômeno ocorre normalmente entre 450℃ e 850℃ (840℉ a 1560℉). carbonetos de cromoque precipitam ao longo dos limites dos grãos, esgotando cromo Essas zonas empobrecidas de cromo tornam-se suscetíveis à corrosão, permitindo que a corrosão ocorra mesmo quando o restante do material permanece intacto.

Como a sensibilização afeta sua tubulação

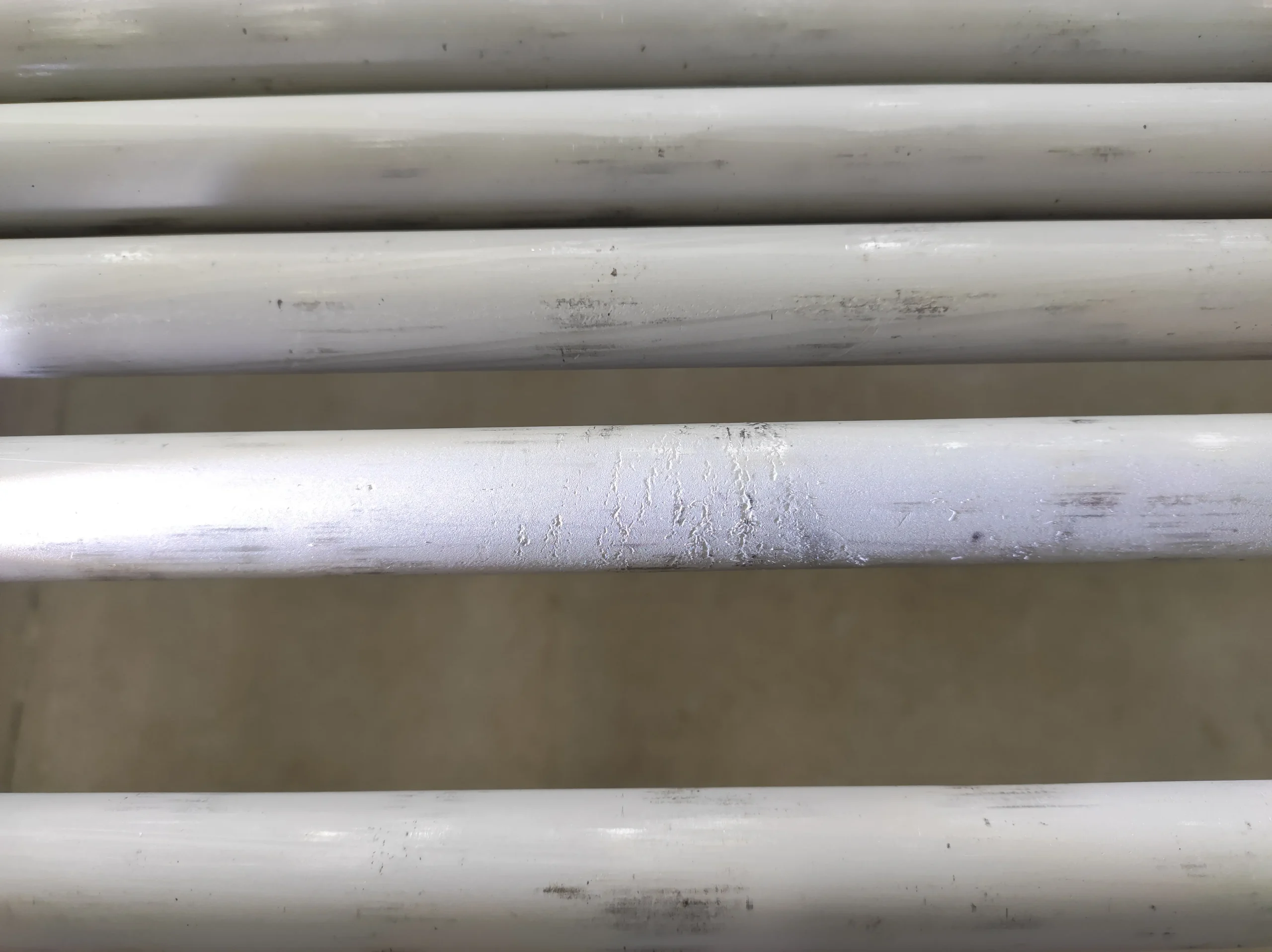

As áreas sensibilizadas não têm cromo suficiente. Elas perdem sua camada passiva. Isso as torna propensas a corrosão intergranular. O ataque ocorre ao longo dos limites dos grãos. Isso enfraquece o material.

Os limites dos grãos corroídos tornam-se pontos fracos. Eles podem levar a rachaduras e fraturas. Isso é especialmente verdadeiro sob estresse. Isso compromete a integridade do tubo.

A sensibilização é difícil de ser vista. A superfície parece normal. As falhas podem ocorrer repentinamente. Isso resulta em vazamentos. Isso causa um perigoso tempo de inatividade do sistema.

A causa mais comum é soldagem. A zona afetada pelo calor (HAZ) fica sensibilizada. Ela é o ponto mais fraco de todo o sistema.

Efeitos de sensibilização em tubos e conexões de aço inoxidável

| Propriedade | Antes da sensibilização | Após a sensibilização |

|---|---|---|

| Resistência à corrosão | Excelente | Ruim (na zona sensibilizada) |

| Microestrutura | Uniforme, limpo | Carbetos nos limites dos grãos |

| Integridade mecânica | Alta | Comprometido |

Como evitar a sensibilização do aço inoxidável

Como evitar a sensibilização do aço inoxidável

| Método | Explicação | Exemplo de notas |

|---|---|---|

| Graus de baixo carbono | Reduz o carbono disponível para carbetos | 304L, 316L |

| Grades estabilizadas | Contém titânio ou nióbio | 321, 347, 316Ti |

- O baixo teor de carbono do 304L suprime a sensibilização durante a soldagem, tornando-o a opção ideal para componentes soldados.

- O 316Ti estabiliza a composição da liga com titânio, impedindo de forma eficaz degradação da soldatornando-o a melhor opção para ambientes de alta temperatura.

Prevenção da sensibilização: fabricação e tratamento

- Recozimento de solução: Este é um tratamento térmico. Ele aquece o aço a uma temperatura alta. Em seguida, o aço é resfriado rapidamente. Isso dissolve os carbonetos de cromo. Isso restaura a camada passiva.

- Soldagem controlada: Use baixa entrada de calor métodos de soldagem. Isso reduz o tempo que o material passa na faixa de temperatura de sensibilização.

- Limpeza pós-soldagem: Limpe bem a área de solda. Remova toda a coloração térmica e os óxidos. Em seguida, passe a superfície. Isso restaura a camada protetora.

Talvez você também queira ler:

Aço inoxidável superaustenítico | Classes | Propriedades | Desempenho

Aço inoxidável versus aço carbono: Qual é o melhor para tubos e conexões?

O que é endurecimento por envelhecimento do aço inoxidável?

O significado das letras após as classes de aço inoxidável

O que é deformação por fluência em aço inoxidável?

Qual é o papel do molibdênio nos tubos e conexões de aço inoxidável?

Impact of Internal Pipe Corrosion

Contate-nos

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/