What is carbide in Stainless ? Трубы из нержавеющей стали а также арматура are widely used, however they do have weaknesses. Carbides are formed under specific conditions and can seriously affect performance. It can lead to your piping system facing collapse.

What Is Carbide In Stainless? Microscopic Compounds!

Carbides are compounds formed when carbon atoms combine with metal atoms. In stainless steels, chromium carbides are the most common and form especially when heated. They can appear in grain boundaries and can alter the properties of the material. Sometimes, this change is harmful.

The effect of carbides on stainless steel

Chromium carbides consume chromium. By drawing chromium from surrounding areas, these areas lose their corrosion resistance. This makes the material vulnerable to attack, which is called sensitisation.

The carbide network makes stainless steel brittle and reduces ductility. It increases the risk of cracking under stress. This can compromise the mechanical integrity of the material.

Carbide formation reduces toughness. Meaning the material absorbs less energy before fracture. This is critical in applications subjected to shock loading.

Carbides are formed during welding, which affects the heat affected zone (HAZ). This can lead to intergranular corrosion after welding, so the correct welding method is essential.

These negative effects shorten the service life of the material. Failures occur, leading to costly repairs and increased downtime.

What is a common carbide in stainless steel

| Carbide Type | Описание | Formation Conditions | Primary Impact |

|---|---|---|---|

| Хром Carbides | Cr-rich, C-containing | Sensitizing temp range(450−850°C) | Межкристаллитная коррозия |

| Molybdenum Carbides | Mo-rich, C-containing | High temperatures, long exposure | Embrittlement |

| Титана Carbides | Ti-rich, C-containing | During solidification, stabilization | Neutralizes carbon |

| Niobium Carbides | Nb-rich, C-containing | During solidification, stabilization | Neutralizes carbon |

Что мы делаем

Strategies to Control Carbides

| Strategy | Action | Benefit for Stainless Steel |

|---|---|---|

| Low Carbon Grades | Use “L” grades (e.g., 304L, 316L) | Reduces carbide formation |

| Stabilized Grades | Add Ti or Nb (e.g., 321, 347, 316Ti) | Carbon forms stable carbides |

| Solution Annealing | High temp heat treatment, rapid cool | Dissolves carbides, restores Cr |

| Proper Welding | Control heat input, fast cooling | Minimizes sensitization |

| Post-Weld Treatment | Cleaning, passivation | Restores protective layer |

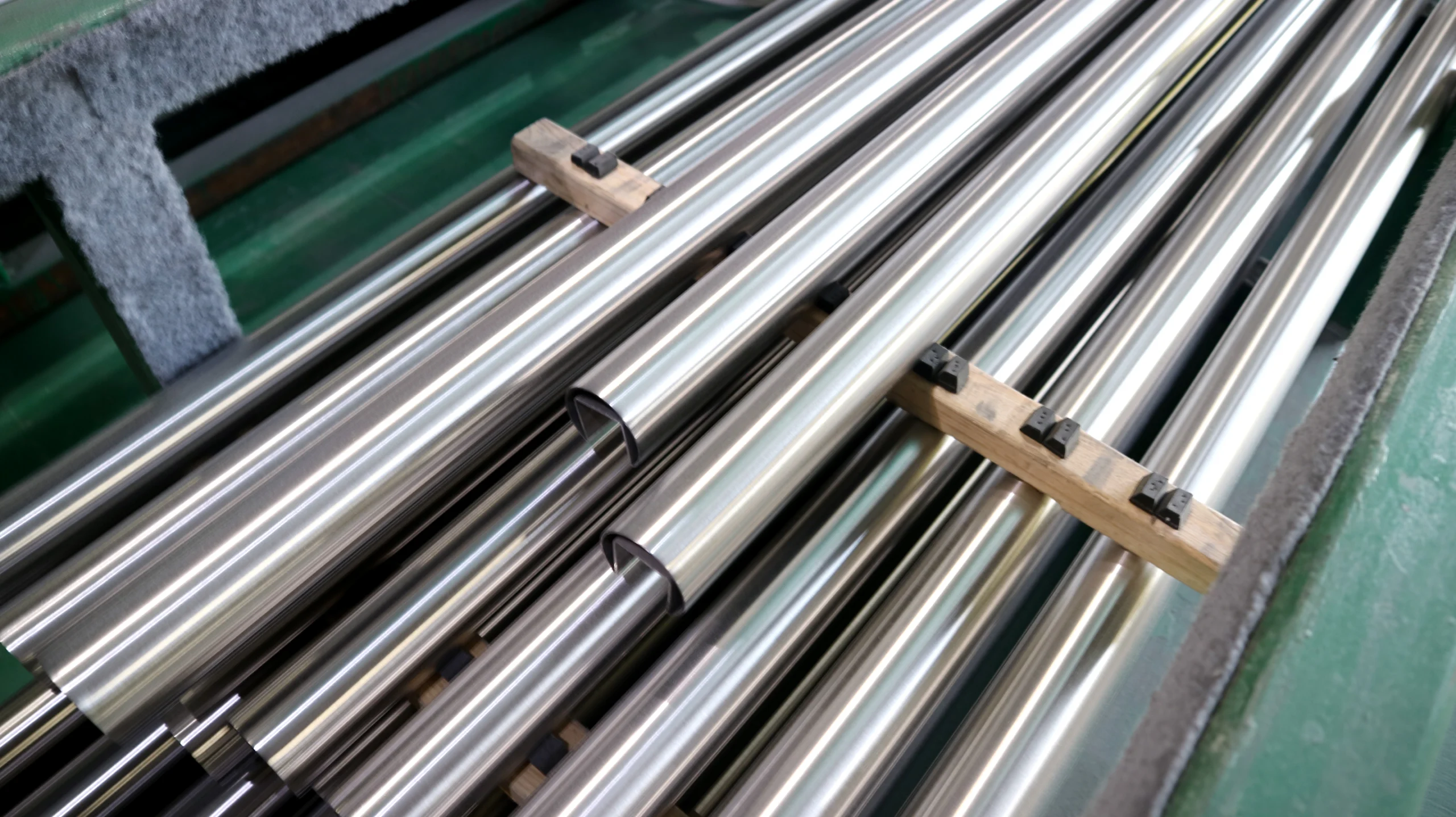

What Is Carbide in Stainless Steel Pipe and Fittings

Carbide formation is a major concern for stainless steel pipe and fittings. This is especially true after welding.

- Welded joints: The heat affected zone (HAZ) is fragile. Carbides can form during welding, leading to post-weld intergranular corrosion.

- High Temperature Service: Pipes working at high temperatures are at risk of sensitisation due to prolonged exposure. This can lead to long-term degradation.

- Corrosive environments: Sensitive areas are susceptible to erosion and they corrode faster than the host material. This can lead to leaks and failures.

- Manufacturing processes: Any heating during manufacturing can induce carbides, including bending or moulding operations. For this reason, proper control is essential.

Sourcing Reliable Components

Choose a manufacturer who has extensive experience with stainless steel and who understands its unique properties. This ensures optimal moulding results.

Look for state-of-the-art tooling capabilities, precision tooling is critical and can affect part quality and consistency.

Ensure rigorous качественный checks are in place, including dimensional checks, etc. Material integrity verification and material test reports are also critical.

Work with reputable manufacturers who offer reliable stainless steel products and have certifications(e.g. ISO 9001 and CE-PED).

Confirm that the manufacturer can meet your production volume requirements. They should handle both prototyping and volume production.

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/