Molybdenum in stainless steel can be helpful in aggressive conditions. It transforms ordinary steel into a high-performance alloy that ensures трубы из нержавеющей стали а также арматура созданы для того, чтобы служить долго.

What Is Molybdenum in Stainless Steel? A Game Changer!

Molybdenum in stainless steel is a powerful alloying element that greatly enhances performance. It mainly enhances коррозионная стойкость and increases strength at high temperatures. In specialised steel grades, molybdenum is usually present in amounts of between 2 and 7%. This small addition makes a big difference.

Key Benefits of Molybdenum in Stainless Steel

Molybdenum stabilises the passive layer, making it more resistant to chloride attack, which greatly reduces the likelihood of питтинг. This is critical for seawater or chemical applications.

It prevents localised corrosion in tight spaces. Molybdenum helps maintain passivation. It resists corrosion where oxygen is limited. This is critical for flanges and fittings.

Molybdenum improves high-temperature strength and prevents creep distortion. This gives stainless steel reliable properties that excel in high-temperature processing.

Molybdenum improves resistance to коррозионное растрескивание под напряжением. It alters the passive film, which makes the material more resistant to stress. This improves the safety of critical systems.

Molybdenum enhances resistance to a wide range of chemicals, including sulphuric, phosphoric and organic acids. This makes the material versatile and suitable for a wide range of industrial piping.

Molybdenum's Role in Stainless Steel

| Role | Mechanism | Effect on Stainless Steel |

|---|---|---|

| Passive Layer Enhancer | Forms stable molybdenum oxides | Boosts corrosion resistance |

| Chloride Blocker | Competes with chlorides | Resists питтинг |

| Solution Strengthener | Solid solution hardening | Improves high-temp strength |

| Carbide Former | Forms beneficial карбиды | Refines microstructure |

| Hydrogen Embrittlement | Can influence resistance | Complex interaction |

Что мы делаем

Molybdenum-Containing Stainless Steel Grades

| Оценка | Molybdenum (%) | Основные области применения |

|---|---|---|

| 316 / 316L | 2.0 – 3.0 | Marine, chemical, food processing, medical |

| 317L | 3.0 – 4.0 | Pulp & paper, chemical plants, condensers |

| Дуплекс (например, 2205) | 2.5 – 3.5 | Offshore, chemical tankers, structural |

| Супер Дуплекс (например, 2507) | 3.5 – 5.0 | Seawater systems, highly corrosive environments |

| 6% Mo Super Aust. (e.g., 254SMO) | 6.0 – 7.0 | Flue gas desulfurization, bleaching, offshore |

| Hastelloy / Inconel | 8.0 – 18.0 | Extreme acids, high-temp chemical processing |

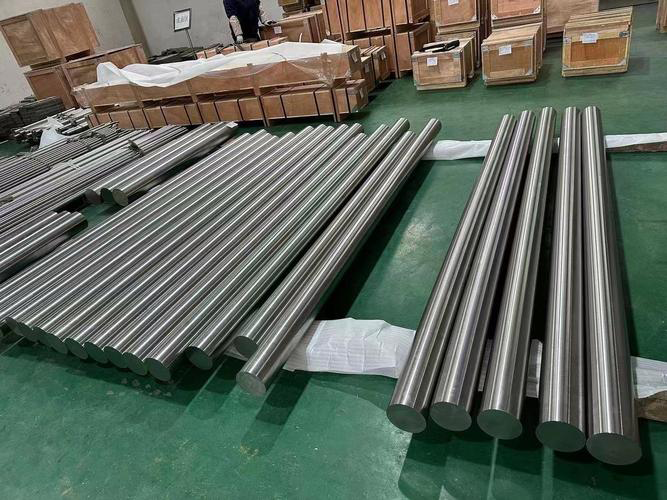

Molybdenum in Stainless Steel Pipe and Fittings Applications

- Chemical Treatment: Pipes and fittings can handle aggressive acids. Molybdenum has important corrosion resistance and ensures a long service life.

- Marine And Offshore: Seawater systems require high resistance to pitting, and molybdenum-rich grades are resistant to chlorides.

- Pulp And Paper Industry: Bleaching plants use highly corrosive chemicals, which are resisted by molybdenum-rich stainless steels.

- Pharmaceutical Industry: High purity and corrosion resistance are essential. Molybdenum-containing steels resist aggressive cleaning solutions.

- Теплообменники: Pipes and tubes operate at high temperatures. Molybdenum increases strength and also resists corrosion from process fluids.

Sourcing Molybdenum-Rich Stainless Steel

Выберите производитель, имеющий большой опыт работы с нержавеющей сталью и понимающий ее уникальные свойства. Это обеспечивает оптимальные результаты формовки.

Обратите внимание на современные возможности оснастки: точность оснастки имеет решающее значение и может влиять на качество и согласованность деталей.

Обеспечить строгий качественный проверки, включая проверку размеров и т.д. Проверка целостности материала и протоколы испытаний материалов также имеют решающее значение.

Работа с авторитетные производители которые предлагают надежную продукцию из нержавеющей стали и имеют сертификаты(например. ISO 9001 и CE-PED).

Убедитесь, что производитель может удовлетворить ваши требования к объему производства. Они должны работать как с прототипами, так и с серийным производством.

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/