Let’s bring the conversation to the aluminium flange.The choice of each component in the труба а также фитинг affects the performance of the system. Traditional фланцы can add significant weight. This creates design and installation challenges. Aluminium flanges, on the other hand, offer a compelling alternative and are well suited to a variety of industrial applications.

What is an Aluminium Flange? A Modern Connection!

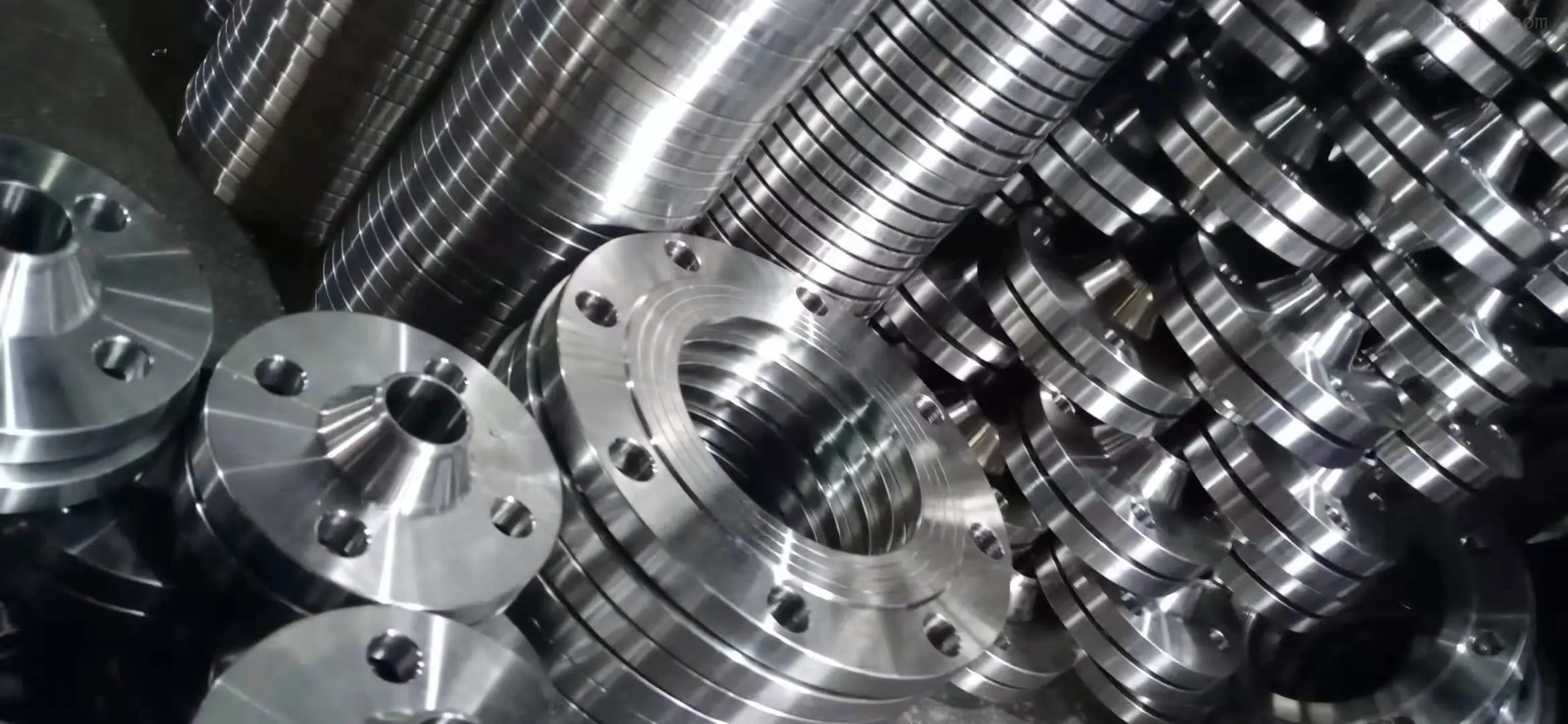

The aluminium flange is an important connecting component. It connects трубы, клапаны, pumps and other equipment. It acts as a leak-proof seal in piping systems. These flanges are machined from various aluminium alloys and are known for their excellent strength-to-weight ratio. It provides a strong connection without creating unnecessary weight.

Core Advantages of an Aluminium Flange

For engineering teams, aluminium flanges offer significant advantages. These advantages translate directly into operational advantages а также cost savings.

An aluminium flange weighs significantly less. This reduces overall system weight. It simplifies installation and transport. This translates to lower labor costs and easier handling for your teams.

Aluminum naturally forms a protective oxide layer. This provides superior resistance to атмосферная коррозия. It also performs well against many chemicals. This extends the service life of your piping components.

Aluminum is an excellent heat conductor. An aluminium flange helps dissipate heat efficiently. This can be beneficial in certain thermal management applications. It promotes system stability.

While specific costs vary, an aluminium flange can offer savings. Reduced shipping weight lowers freight charges. Easier installation also cuts labor expenses. Its durability means fewer replacements.

Aluminum is highly recyclable. An aluminium flange supports environmental initiatives. Choosing sustainable материалы improves your company’s green credentials. It appeals to eco-conscious clients.

Common Aluminium Flange Types & Uses

| Тип фланца | Description & Primary Use |

|---|---|

| Slip-On Flange | Slips over the pipe. Welded inside and out. Easy alignment. |

| Фланец со сварной горловиной | Long tapered hub. Welds to pipe. Best for high pressure/temp. |

| Заглушка | Seals off pipe ends. No bore. For pressure testing or future extension. |

| Фланец соединения внахлест | Two pieces: stub end and backing flange. Ideal for pipe rotation. |

| Резьбовой фланец | Screwed onto pipe. No welding needed. For low-pressure, non-cyclic use. |

Получить PDF файл Фланец

Typical Aluminium Flange Material Grades

| Alloy Grade | Характеристики | Общие приложения |

|---|---|---|

| 6061-T6 | General purpose. Good strength, weldability, corrosion resistance. | Structural components, marine, general piping. |

| 6063-T5/T6 | Good finish, weldability. Often for architectural, light structural. | Architectural systems, light-duty fluid lines. |

| 5083-H111 | High strength, excellent corrosion resistance (marine). | Shipbuilding, cryogenic vessels, offshore. |

| 7075-T6 | Very high strength. Less corrosion resistance. For aerospace. | High-stress parts (rarely standard flanges). |

Aluminium vs. Stainless Steel Flanges

| Характеристика | Алюминиевый фланец | Фланец из нержавеющей стали |

|---|---|---|

| Масса | Much Lighter | Heavier |

| Corrosion Env. | Atmospheric, some chemicals, freshwater | Broad range of chemicals, high temps/pressures |

| Температура | Lower/Moderate (up to ~200°C) | High (up to ~800°C or more) |

| Pressure | Lower/Moderate | High/Very High |

| Сила | Good Strength-to-Weight | High Overall Strength |

| Typical Use | HVAC, instrumentation, low-pressure fluids | Process piping, high-pressure steam, corrosive chemicals |

Installation and Maintenance of Aluminium Flanges

- Gasket Selection:

Use appropriate gaskets. Non-asbestos or PTFE gaskets are common. These ensure a tight, leak-free seal. - Bolt Torquing:

Apply proper torque specifications. Uneven tightening can cause leaks. Use a torque wrench for precision. - Material Compatibility:

Ensure no galvanic corrosion occurs. Isolate dissimilar metals if necessary. This prevents деградация. - Regular Inspection:

Periodically check for signs of wear. Look for any leaks or corrosion. Proactive maintenance extends lifespan.

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/