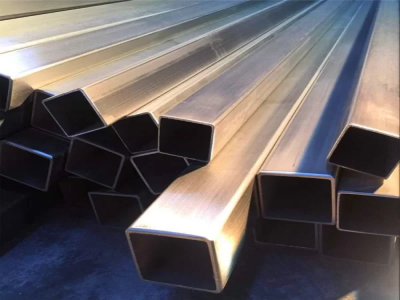

2.4856 Nickel Alloy Pipe is designed for the most demanding conditions. Standard stainless steel can be prone to corrosion and cause your piping system to fail. Ensure your трубы из нержавеющей стали а также фитинги из нержавеющей стали have a long-lasting life.

What is 2.4856 Nickel Alloy Pipe? A High-Performance Champion!

2.4856 Nickel alloy tubing is a European name that refers to alloy 625 (UNS N06625). It is a nickel-chromium-molybdenum alloy with high strength and excellent corrosion resistance, especially in a variety of corrosive media. Its robust composition makes it an ideal material for use in extremely суровые условия.

Key Advantages of 2.4856 Nickel Alloy Pipe

This alloy is resistant to a wide range of corrosive chemicals. It excels in both oxidizing and reducing acids. Also resists питтинг а также щелевая коррозия.

Maintains excellent strength. From low temperatures to 1000 °C(1832℉), making 2.4856 nickel alloy tubing a good material for high-pressure systems.

High nickel content prevents коррозионное растрескивание под напряжением and sudden brittle failure.

Despite its high strength, alloy 625 is easy to weld. Forms strong, ductile welds.

Resists oxidation and carburization. Maintains good mechanical properties at high temperatures. It is also resistant to деформация ползучести.

Global Designations for 2.4856 Nickel Alloy Pipe

- EN: 2.4856

- UNS: N06625

- ASTM: B443,B704,B705,B366,B564,B444,B446

- ASME: SB444, SB474, SB704, SB705

- DIN: 17744 / 17752 / EN 10095

- ISO:6208

- GB:NS3306

Chemical Composition of 2.4856

| Элемент | Ni | Cr | Пн | Nb | Fe | C | Mn | Si | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Содержание (%) | ≥58.0 | 20.0-23.0 | 8.0-10.0 | 3.15-4.15 | ≤5.0 | ≤0.10 | ≤0.50 | ≤0.50 | ≤0.40 | ≤0.40 |

Mechanical Properties of 2.4856

| Имущество | Предел прочности | Предел текучести | Удлинение | Твердость | Плотность | Диапазон плавления |

|---|---|---|---|---|---|---|

| Ценить | ≥827 MPa (120ksi) | ≥414 MPa (60ksi) | ≥30% | ≤220 | 8.43g/cm³ | 1350−1420℃ |

Get 2.4856 Pipe Quote

Applications for 2.4856 Nickel Alloy Pipe

- Chemical treatment: Handles highly corrosive acids and mixed chemicals due to its wide range of corrosion resistance. It is used in reactors, heat exchangers and transmission piping.

- Aerospace industry: It can withstand extreme temperatures and pressures and has a high strength-to-weight ratio, and is used in engine exhaust systems and thrust reversers.

- Marine & Offshore: Resistant to seawater and chloride stress corrosion, this alloy is used for submarine components, propeller shafts and offshore risers.

- Pollution Control: Flue gas desulfurization (FGD) systems benefit greatly. Its resistance to highly corrosive acidic condensates ensures a long service life.

- Oil and gas: Downhole tubing, sour gas applications and process equipment. It resists hydrogen sulfide, carbon dioxide and chlorides.

- Power generation: Heat exchangers, furnace components and superheaters can use 625 alloy because of its ability to maintain strength at high temperatures.

Alloy 625 vs. Alloy 601 vs. Hastelloy C276

| Характеристика | Alloy 625 (2.4856) | Alloy 601 | Хастеллой C276 |

|---|---|---|---|

| Primary Advantage | Broad Corrosion, Strength | High-Temp Oxidation | Extreme Corrosion |

| Key Alloy Element | Mo, Nb | Al | High Mo, W |

| Общее использование | Chemical, Marine, Aero | Furnaces, Heat Treat | Chemical,Environmental and Energy |

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/