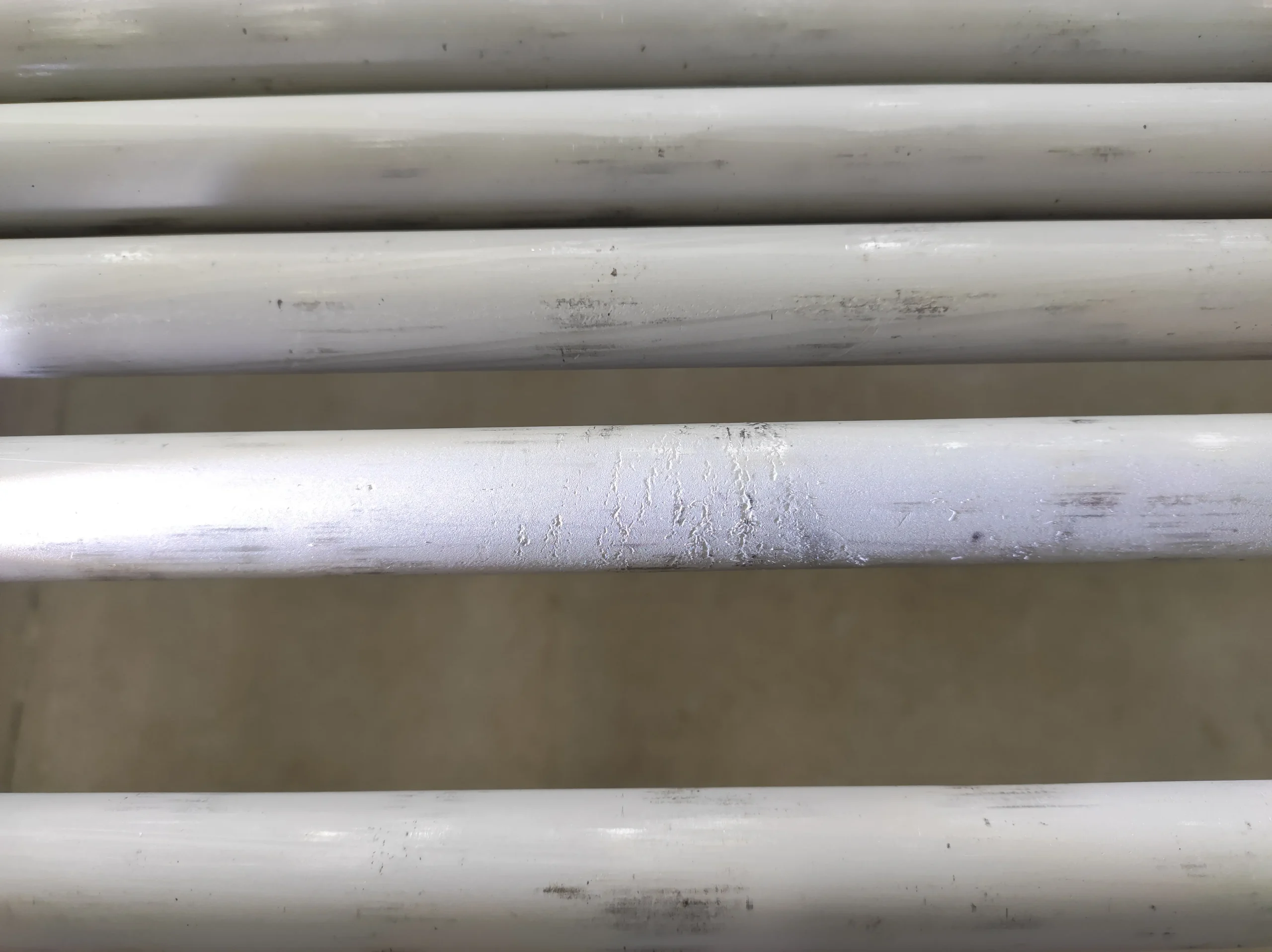

Трубы из нержавеющей стали а также фитинги из нержавеющей стали сделанный из Нимоник 80А являются отличным решением для трубопроводных систем, подвергающихся экстремальным нагрузкам. Этот высокоэффективный сплав способен выдерживать высокие термические и механические нагрузки.

Nimonic 80A | UNS N07080

Nimonic 80A является членом Нимоновый сплав семья, которая также является сплав на основе никеля. В его состав входят титан и алюминий - элементы, которые позволяют ему быть закаленные возрастом. Этот процесс значительно увеличивает его механические свойства а также противостоит деформации при ползучести. Он надежно работает при температурах до 815°C (1500°F).

Основные преимущества Nimonic 80A

Nimonic 80A сопротивляется деформация ползучести и сохраняет свою форму при длительном воздействии высоких температур и нагрузок.

Сплав сохраняет стабильность при температурах до 815°C (1500°F) и предотвращает тепловое размягчение.

Высокий содержание хрома защищает поверхности от окисления в условиях высоких температур.

Нержавеющая сталь Nimonic 80A VS 310S

| Характеристика | Нимоник 80А | Нержавеющая сталь 310S |

|---|---|---|

| Стоимость | Высокий | Средний |

| Изготовление | Требуются конкретные термическая обработка | Легче, чаще |

| Сопротивление ползучести | Превосходно | Хорошо |

| Основное использование | Компоненты, подвергающиеся высоким нагрузкам и высоким температурам | Высокотемпературные, ненагружаемые |

Химический состав

| Элемент | Ni | Cr | Ti | Al | Fe | C | Si | Mn |

|---|---|---|---|---|---|---|---|---|

| Содержание (wt%) | Остаток средств | 18.0-21.0 | 1.80-2.70 | 1.00-1.80 | 3.0 Макс | 0.10 Макс | 1.0 Макс | 1.0 Макс |

Механические свойства

| Имущество | Предел прочности | Предел текучести (смещение 0,2%) | Удлинение | Твердость (HRC) | Макс. Температура обслуживания |

|---|---|---|---|---|---|

| Значение (типичное) | ≥980МПа(142ksi) | ≥590 МПа (85.5ksi) | ≥15 | ≥25 | До 815℃ (1500℉) |

Nimonic 80A в высокотемпературных трубопроводных системах

- Высокотемпературные болты и крепеж: Противостоит ползучести, сохраняет целостность соединения и является предпочтительным выбором для соединения высокотемпературных фланцев.

- Турбинные лопатки: Широко используется в газовых турбинах. Они выдерживают высокую температуру и нагрузки и имеют решающее значение для аэрокосмической промышленности и энергетики.

- Трубки для теплообменников: Трубки теплообменников должны выдерживать термоциклирование, и эти компоненты полагаются на чрезвычайную прочность Nimonic 80A.

- Трубопроводные системы: Может использоваться для ответственных фитингов из нержавеющей стали, таких как выхлопные системы высокого давления. Эти компоненты требуют такой же высокой прочности, как и трубы теплообменников.

Поиск и изготовление Nimonic 80A

Полный Отчет об испытаниях материала (MTR) является обязательным. Он проверяет точный состав сплава и гарантирует его работоспособность.

Работа с специализированные поставщики труб и фитингов из нержавеющей стали. Они разбираются в этих легированных сталях и могут обеспечить надлежащее изготовление и контроль качества, а также ISO 9001 и CE-PED сертифицированный.

Она трудно поддается обработке и требует специальных инструментов. Для обеспечения целостности сварного шва необходимы особые технологии сварки.

Он стоит дорого, поэтому важно оценить, насколько долговечен продукт. Это может оправдать его более высокую первоначальную стоимость.

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/