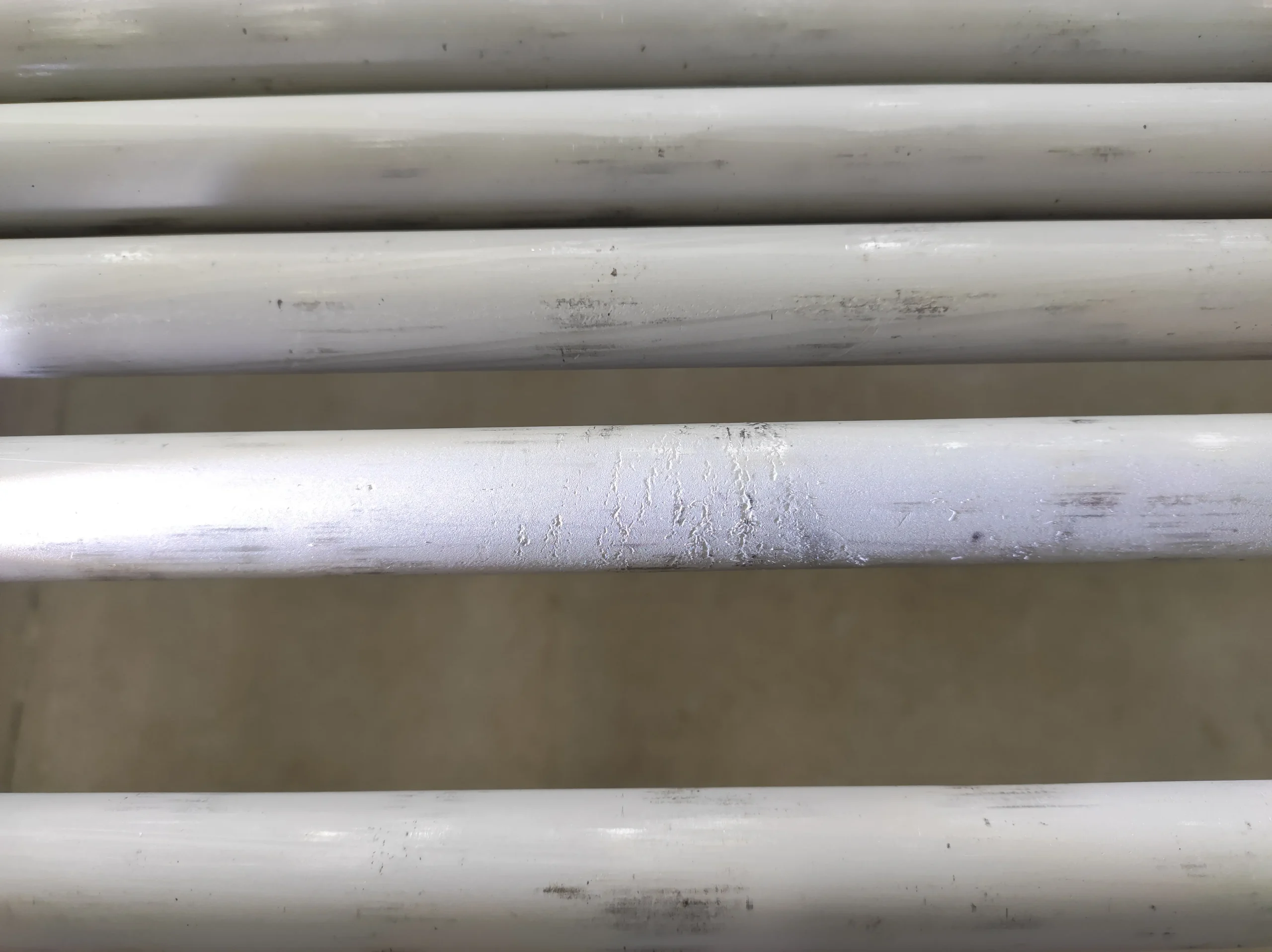

Со временем, деградация материалов из нержавеющей стали возникает. Однако системы трубопроводов транспортируют жизненно важные жидкости, что может привести к утечкам и сбоям. Понимание этих процессов имеет жизненно важное значение и гарантирует, что ваши трубы из нержавеющей стали а также фитинги из нержавеющей стали созданы для того, чтобы служить долго.

Что такое деградация материалов из нержавеющей стали? Постоянная борьба!

Деградация материалов из нержавеющей стали означает, что их свойства со временем ухудшаются. Это происходит под воздействием окружающей среды. Коррозия является основной причиной, как и механическое напряжение. Понимание этих механизмов помогает предотвратить поломку.

Основные формы деградации материалов из нержавеющей стали

Межкристаллитная коррозия стирает границы зерен. Это происходит после сенсибилизации (хром истощение). Частой причиной является сварка, ослабляющая материал изнутри.

СКК представляет собой комбинацию растягивающего напряжения и коррозионная среда. Трещины могут быстро расширяться, что приводит к внезапному разрушению. Частым виновником этого являются хлориды.

Включает эрозию материалов под действием потока жидкости, а также химическое воздействие. Это усугубляется высокоскоростными жидкостями, влияющими на сгибы и зоны турбулентности.

Повторяющиеся циклические нагрузки приводят к усталости, в результате которой образуются и расширяются микротрещины, что в конечном итоге приводит к разрушению. Часто встречается в вибрирующих трубопроводных системах.

Факторы и их влияние на нержавеющую сталь

| Фактор | Описание | Риск для труб/фитингов |

|---|---|---|

| Коррозионные среды | Кислоты, хлориды, соединения серы | Питтинг, общая коррозия |

| Высокая температура | Повышенные рабочие температуры | Окисление, сенсибилизация, жуть |

| Механическое напряжение | Давление, вибрация, внешние нагрузки | SCC, усталость, деформация |

| Состояние поверхности | Шероховатость, загрязнения, сварные швы | Локализованная коррозия, точечная коррозия |

| Дефекты материалов | Включения, неправильная термическая обработка | Снижение стойкости, преждевременный выход из строя |

| Скорость жидкости | Высокая скорость потока | Эрозия-коррозия |

Что мы делаем

Стратегии профилактики для нержавеющей стали

| Стратегия | Действие | Выгода для труб/фитингов |

|---|---|---|

| Выбор класса | Выберите подходящий сплав нержавеющей стали | Устойчивость к специфическим средам |

| Правильный дизайн | Избегайте щелей, застойных зон, мест напряжения | Уменьшить количество локализованных атак |

| Отделка поверхности | Полировка, электрополировка | Повышение коррозионной стойкости |

| Послесварочная обработка | Очистка, пассивация, отжиг сварных швов | Предотвратить послесварочная коррозия |

| Защитные покрытия | Применяйте специализированные барьеры | Добавьте дополнительную защиту |

| Мониторинг | Регулярный осмотр, неразрушающие испытания | Обнаружение ранней деградации |

Влияние деградации материалов из нержавеющей стали

- Эксплуатационные неисправности: Утечки из-за старения труб. Это может привести к незапланированным простоям. Производственные потери могут быть значительными.

- Опасности, связанные с безопасностью: Утечка опасных жидкостей представляет опасность и наносит вред окружающей среде.

- Увеличение расходов: Дорогостоящий ремонт и замена деталей увеличивают капитальные затраты и повышают эксплуатационные расходы.

- Сокращение срока службы: Оборудование быстрее изнашивается, что сокращает срок его службы. Отсюда необходимость в скорейшей замене.

- Вопросы соответствия нормативным требованиям: Ошибки могут привести к несоблюдению нормативных требований, что чревато штрафами и подрывом репутации компании.

Поиск надежных компонентов

Выберите производитель, имеющий большой опыт работы с нержавеющей сталью и понимающий ее уникальные свойства. Это обеспечивает оптимальные результаты формовки.

Обратите внимание на современные возможности оснастки: точность оснастки имеет решающее значение и может влиять на качество и согласованность деталей.

Обеспечить строгий качественный проверки, включая проверку размеров и т.д. Проверка целостности материала и протоколы испытаний материалов также имеют решающее значение.

Работа с авторитетные производители которые предлагают надежную продукцию из нержавеющей стали и имеют сертификаты(например. ISO 9001 и CE-PED).

Убедитесь, что производитель может удовлетворить ваши требования к объему производства. Они должны работать как с прототипами, так и с серийным производством.

Возможно, вы также захотите прочитать:

Что такое H и L нержавеющая сталь - Дуплексные трубы

Что такое карбид в нержавеющей стали? Как они влияют на трубы и фитинги?

Что такое деформация ползучести в нержавеющей стали?

Что такое возрастное упрочнение нержавеющей стали?

Значение букв в названиях марок нержавеющей стали

Нержавеющая сталь VS углеродистая сталь: Что лучше для труб и фитингов?

Как смягчить нержавеющую сталь? Каковы преимущества и недостатки?

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/