Что такое карбид в нержавеющей ? Трубы из нержавеющей стали а также арматура широко используются, однако у них есть недостатки. Карбиды образуются при определенных условиях и могут серьезно повлиять на производительность. Это может привести к разрушению трубопроводной системы.

Что такое карбид в нержавеющей стали? Микроскопические соединения!

Карбиды - это соединения, образующиеся при соединении атомов углерода с атомами металла. В нержавеющих сталях, хром Карбиды являются наиболее распространенными и образуются, прежде всего, при нагревании. Они могут появляться на границах зерен и изменять свойства материала. Иногда это изменение бывает вредным.

Влияние карбидов на нержавеющую сталь

Карбиды хрома потребляют хром. Вытягивая хром из окружающих областей, эти области теряют свою коррозионную стойкость. Это делает материал уязвимым для атаки, что называется сенсибилизацией.

Карбидная сеть делает нержавеющую сталь хрупкой и снижает ее пластичность. Это повышает риск образования трещин под действием напряжения. Это может нарушить механическую целостность материала.

Образование карбидов снижает вязкость. Это означает, что материал поглощает меньше энергии до разрушения. Это имеет решающее значение для применений, подверженных ударным нагрузкам.

Во время сварки образуются карбиды, которые влияют на зону термического влияния (HAZ). Это может привести к межкристаллитной коррозии после сварки, поэтому правильный метод сварки очень важен.

Эти негативные эффекты сокращают срок службы материала. Возникают поломки, приводящие к дорогостоящему ремонту и увеличению времени простоя.

Что такое обычный карбид в нержавеющей стали

| Тип карбида | Описание | Условия формирования | Первичное воздействие |

|---|---|---|---|

| Хром Карбиды | Богатый Cr, содержащий C | Диапазон температур сенсибилизации (450-850°C) | Межкристаллитная коррозия |

| Молибден Карбиды | Мо-богатый, С-содержащий | Высокие температуры, длительное воздействие | Охрупчивание |

| Титана Карбиды | Богатые титаном, содержащие С | Во время застывания стабилизация | Нейтрализует углерод |

| Карбиды ниобия | Богатые Nb, содержащие C | Во время застывания стабилизация | Нейтрализует углерод |

Что мы делаем

Стратегии борьбы с карбидами

| Стратегия | Действие | Преимущества нержавеющей стали |

|---|---|---|

| Низкоуглеродистые сорта | Используйте Оценки "L" (например, 304L, 316L) | Уменьшает образование карбидов |

| Стабилизированные грейды | Добавьте Ti или Nb (например, 321, 347, 316Ti) | Углерод образует устойчивые карбиды |

| Отжиг раствора | Высокотемпературная термообработка, быстрое охлаждение | Растворяет карбиды, восстанавливает Cr |

| Правильная сварка | Контроль подачи тепла, быстрое охлаждение | Минимизирует сенсибилизация |

| Послесварочная обработка | Очистка, пассивация | Восстанавливает защитный слой |

Что такое карбид в трубах и фитингах из нержавеющей стали

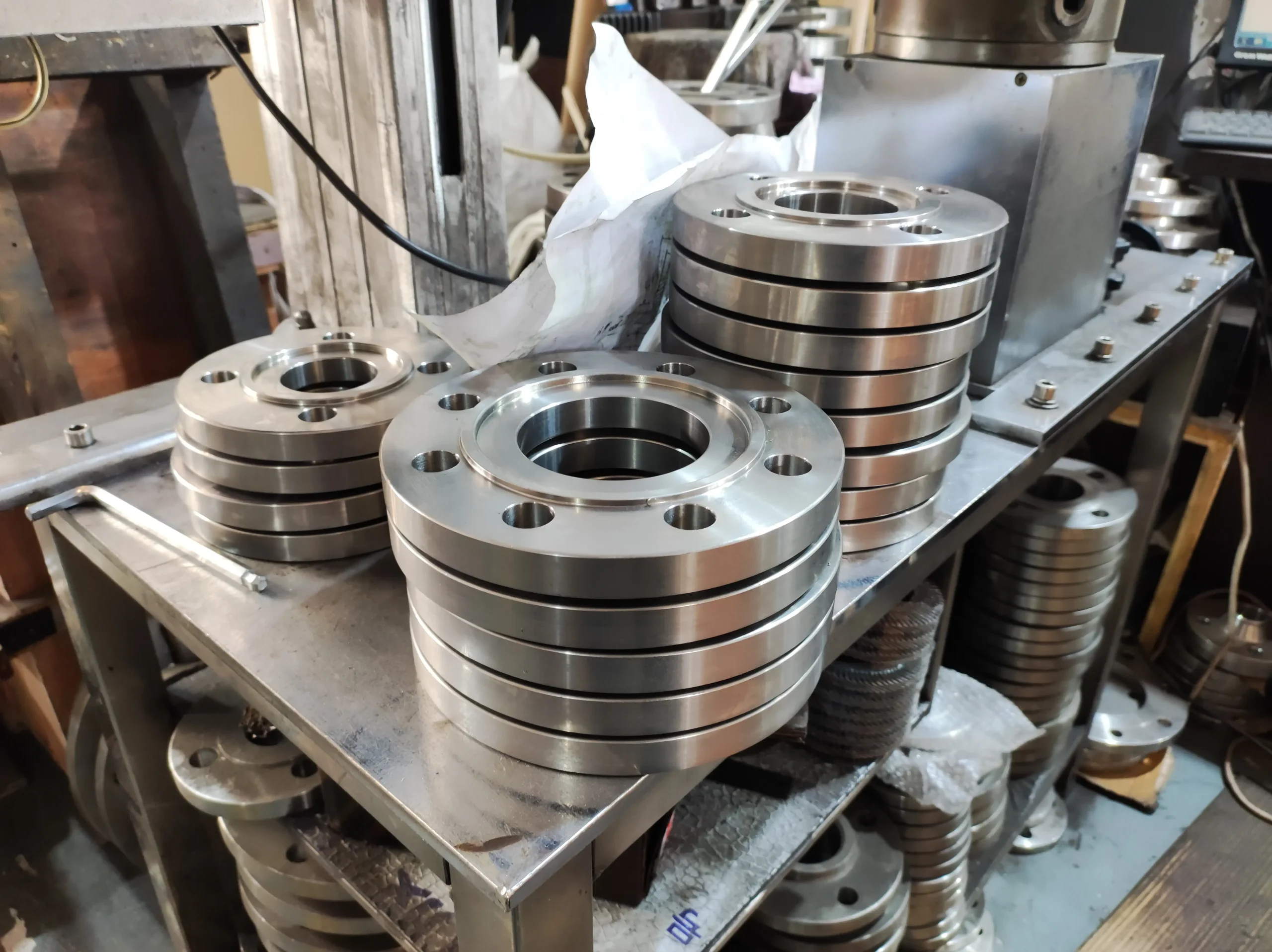

Образование карбидов является основной проблемой для труб и фитингов из нержавеющей стали. Это особенно актуально после сварки.

- Сварные соединения: Зона термического влияния (ЗТВ) является хрупкой. Во время сварки могут образовываться карбиды, что приводит к послесварочным повреждениям межкристаллитная коррозия.

- Работа при высоких температурах: Трубы, работающие при высоких температурах, подвержены риску сенсибилизации из-за длительного воздействия. Это может привести к длительному деградация.

- Коррозионные среды: Чувствительные участки подвержены эрозии, и они корродируют быстрее, чем основной материал. Это может привести к утечкам и поломкам.

- Производственные процессы: Любой нагрев в процессе производства может привести к образованию карбидов, включая операции гибки или формовки. По этой причине необходим надлежащий контроль.

Поиск надежных компонентов

Выберите производитель, имеющий большой опыт работы с нержавеющей сталью и понимающий ее уникальные свойства. Это обеспечивает оптимальные результаты формовки.

Обратите внимание на современные возможности оснастки: точность оснастки имеет решающее значение и может влиять на качество и согласованность деталей.

Обеспечить строгий качественный проверки, включая проверку размеров и т.д. Проверка целостности материала и протоколы испытаний материалов также имеют решающее значение.

Работа с авторитетные производители которые предлагают надежную продукцию из нержавеющей стали и имеют сертификаты(например. ISO 9001 и CE-PED).

Убедитесь, что производитель может удовлетворить ваши требования к объему производства. Они должны работать как с прототипами, так и с серийным производством.

Возможно, вы также захотите прочитать:

Что такое H и L нержавеющая сталь - Дуплексные трубы

Деградация материалов из нержавеющей стали

Что такое деформация ползучести в нержавеющей стали?

Что такое возрастное упрочнение нержавеющей стали?

Значение букв в названиях марок нержавеющей стали

Нержавеющая сталь VS углеродистая сталь: Что лучше для труб и фитингов?

Как смягчить нержавеющую сталь? Каковы преимущества и недостатки?

Связаться с нами

- RM901 No.22 Tangjiaqiao Road Wenzhou Китай

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/