Sensibilisation de l'acier inoxydable est une question cruciale. Il s'agit d'un changement métallurgique. Elle peut gravement compromettre l'intégrité d'un matériau. Elle est également connue sous le nom de "dégradation de la soudure". Cela se produit dans les cas suivants tuyaux en acier inoxydable et raccords de tuyauterie en acier inoxydable. Il est essentiel de la comprendre. Elle permet d'éviter des échecs inattendus.

Sensibilisation de l'acier inoxydable : une menace cachée

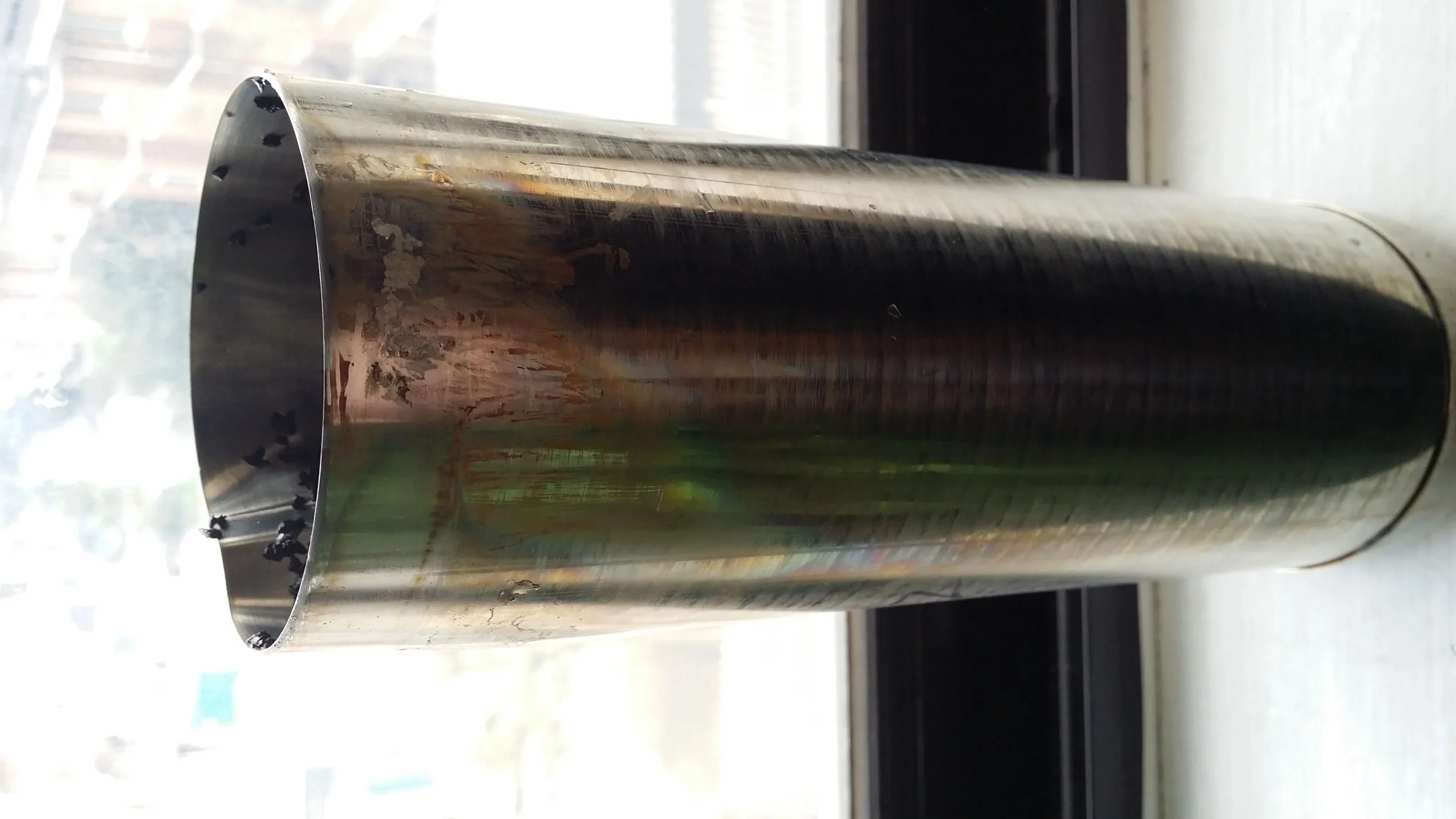

L'acier inoxydable subit une sensibilisation lorsqu'il est chauffé.Ce phénomène se produit généralement entre 450℃ et 850℃(840℉ à 1560℉).Les températures élevées favorisent la formation de... carbures de chromequi précipitent le long des joints de grains, appauvrissant ainsi la couche d'ozone. chrome Ces zones appauvries en chrome deviennent sensibles à la corrosion, ce qui permet à la corrosion de se produire même lorsque le reste du matériau reste intact.

Ce que nous faisons

Comment la sensibilisation affecte-t-elle votre tuyauterie ?

Les zones sensibilisées manquent de chrome. Elles perdent leur couche passive. Elles sont alors sujettes à corrosion intergranulaire. L'attaque se produit le long des joints de grains. Cela affaiblit le matériau.

Les joints de grains corrodés deviennent des points faibles. Ils peuvent entraîner des fissures et des fractures. Cela est particulièrement vrai sous contrainte. Cela compromet l'intégrité de la conduite.

La sensibilisation est difficile à voir. La surface semble normale. Les défaillances peuvent survenir soudainement. Il en résulte des fuites. Elles entraînent des arrêts dangereux du système.

La cause la plus fréquente est soudage. La zone affectée thermiquement (ZAT) est sensibilisée. C'est le point le plus faible de tout le système.

Effets de sensibilisation sur les tuyaux et raccords en acier inoxydable

| Biens | Avant la sensibilisation | Après sensibilisation |

|---|---|---|

| Résistance à la corrosion | Excellent | Pauvre (dans la zone sensibilisée) |

| Microstructure | Uniforme, propre | Carbures aux joints de grains |

| Intégrité mécanique | Haut | Compromis |

Comment prévenir la sensibilisation de l'acier inoxydable ?

Comment prévenir la sensibilisation de l'acier inoxydable ?

| Méthode | Explication | Exemples de notes |

|---|---|---|

| Classes à faible teneur en carbone | Réduit le carbone disponible pour les carbures | 304L, 316L |

| Grades stabilisés | Contient titane ou le niobium | 321, 347, 316Ti |

- La faible teneur en carbone du 304L supprime la sensibilisation pendant le soudage, ce qui en fait un choix idéal pour les composants soudés.

- 316Ti stabilise la composition de l'alliage avec le titane, ce qui empêche efficacement la formation d'une couche d'ozone. dégradation des souduresce qui en fait le meilleur choix pour les environnements à haute température.

Prévention de la sensibilisation : fabrication et traitement

- Recuit de la solution: Il s'agit d'un traitement thermique. Il chauffe l'acier à haute température. Il le refroidit ensuite rapidement. Les carbures de chrome sont ainsi dissous. La couche passive est ainsi rétablie.

- Soudage contrôlé : Utiliser un faible apport de chaleur méthodes de soudage. Cela réduit le temps que le matériau passe dans la plage de température de sensibilisation.

- Nettoyage après soudage: Nettoyer soigneusement la zone de soudure. Enlever toute trace de chaleur et d'oxyde. Ensuite, passez la surface à la passivation. Cette opération rétablit la couche protectrice.

Vous voudrez peut-être aussi lire :

Acier inoxydable super austénitique | Nuances | Propriétés | Performances

Acier inoxydable VS acier au carbone : Quelle est la meilleure solution pour les tuyaux et les raccords ?

Qu'est-ce que le durcissement par vieillissement de l'acier inoxydable ?

Signification des lettres qui suivent les nuances d'acier inoxydable

Qu'est-ce que la déformation par fluage dans l'acier inoxydable ?

Quel est le rôle du molybdène dans les tubes et raccords en acier inoxydable ?

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/