Cobalt-based alloy is known for their excellent properties that provide superior performance. While standard tuyaux en acier inoxydable et raccords de tuyauterie en acier inoxydable often lack the required durability, cobalt-based alloys enhance the stability of the overall piping system. This article will go into detail about it and the reasons why it is a wise choice.

What Is Cobalt-based Alloy? High Performance Alliance!

The main element of cobalt-based alloys is cobalt, while other major elements include chrome, tungsten or molybdène. This composition offers unique advantages; they are known for their high hardness at very high temperatures and excellent wear resistance. They are therefore used when alliages à base de nickel or high-grade stainless steels fail.

Ce que nous faisons

Key Benefits of Cobalt-based Alloy

Cobalt-based alloys are very hard and prevent galling and seizing. They can be used in moving parts to ensure long service life under abrasive conditions.

These alloys retain their mechanical strength, perform reliably at extreme temperatures and resist déformation par fluage.

Resistant to a wide range of corrosive media, including strong acids and high salinity environments. They perform well in both oxidizing and reducing media.

They retain their properties when hot and do not lose strength quickly, making them ideal for high-temperature applications.

Drawbacks of Cobalt-based Alloy

| Drawback | Description | Consideration for Piping |

|---|---|---|

| High Cost | Cobalt is a rare and valuable metal. | Use only in critical situations. |

| Fabrication | Difficult to process, mold and weld. | Requires specialist knowledge. |

| Availability | Production is not as extensive as steel. | May require longer lead time. |

Common Grades and Their Uses

| Grade de l'alliage | Main Features | Applications courantes |

|---|---|---|

| CO50 | High temperature, robust, wear-resistant | Bearings, sleeves, high wear parts |

| MP35N | High strength, excellent corrosion | Marine, medical implants, oil & gas components |

| 188 | High-temp, oxidation resistance | Aircraft turbine components |

| L-605 | Strong, fabricable, high temp | Aerospace, furnace parts |

| 1537 | Wear-resistant, high hardness | Valve trim, hard facing, pump parts |

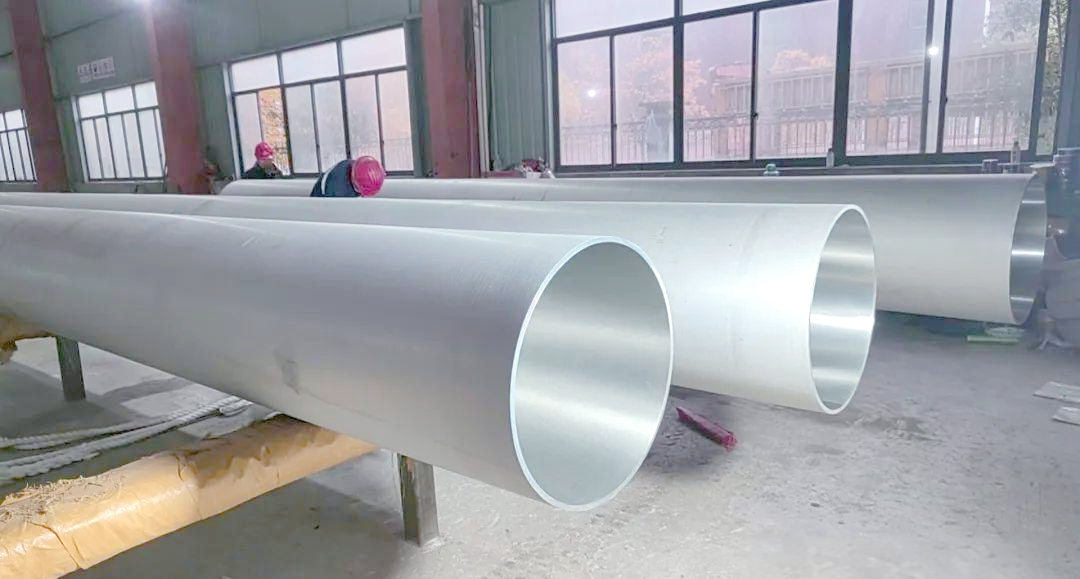

Cobalt-based Alloys in Piping Systems

- Extreme Wear: Soupapes and pumps can handle abrasive media. Cobalt alloys offer better wear resistance and are available for valve trims, valve seats and pump shafts.

- High-temperature Service: Pipes in furnaces and reactors are alloyed with cobalt alloys to withstand high temperatures and chemical attack.

- Corrosive Environments: Specific grades are resistant to highly corrosive media. They serve critical pipelines, including harsh chemical processing pipelines.

- Medical and Bioprocessing: Certain alloys are biocompatible and critical for medical devices, and are also used in sterile pharmaceutical processes.

Sourcing and Fabricating Cobalt-Based Alloys

A complete Material Test Report (MTR) is required. This confirms the exact composition and ensures the characterization of the alloy.

Travailler avec specialized suppliers of stainless steel pipe and fittings. They understand these alloy steels and can ensure proper fabrication and quality control,and are ISO 9001 et CE-PED certified.

These alloys are difficult to work with. They require special tools. Specific procédures de soudage are crucial. This guarantees weld integrity.

These alloys are expensive and it is recommended that they be evaluated for extended service life.

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/