CO50 alloy is designed for the most demanding environments, providing the durability your tuyaux en acier inoxydable et raccords de tuyauterie en acier inoxydable need when faced with severe challenges.

What is CO50 Alloy: A Super Alloy with High Performance

CO50 alloy is a special cobalt-based alloy renowned for its exceptional hardness and excellent wear resistance. It is composed of cobalt, chrome and tungsten, which give it high strength and provide excellent thermal stability. When alliages à base de nickel and high-quality stainless steel fail to meet requirements, it becomes the material of choice.

Ce que nous faisons

Main Advantages of CO50 alloy

CO50 alloy boasts extremely high hardness, effectively preventing galling and seizing. It maintains a long service life even under abrasive and high-friction conditions.

This alloy maintains its mechanical strength under extreme temperatures, reliably withstanding high-temperature environments while resisting déformation par fluage.

It resists various corrosive media, including strong acids and chloride-rich environments. It performs well in both oxidising and reducing media.

It maintains its performance at high temperatures without a rapid decline in strength. This makes it well-suited for high-temperature applications.

Composition chimique

| Élément | Co | Cr | W | Ni | Fe | C |

|---|---|---|---|---|---|---|

| Weight (%) | Équilibre | 28.0 | 16.0 | ≤2.0 | ≤3.0 | 0.10 |

Propriétés mécaniques

| Biens | Dureté | Résistance à la traction | Operating Temp | Creep Strength | Wear Resistance |

|---|---|---|---|---|---|

| Value (Typical) | HRC 40-50 | ≥800 MPa | Up to 1100 ℃ | Excellent | Excellent |

CO50 Alloy VS 316L Stainless Steel

| Fonctionnalité | CO50 Alloy | Acier inoxydable 316L |

|---|---|---|

| Wear | Excellent | Poor to Fair |

| Haute température | Excellent | Good to Fair |

| Corrosion | Excellent | Bon |

| Coût | Très élevé | Low to Medium |

| Fabrication | Difficult | Easy |

Applications of CO50 Alloy in Pipelines and Related Systems

- Valve Trims: CO50 alloy is wear resistant and available for valve seats and plugs.

- Pump Sleeves and Bearings: CO50 alloy has anti-friction and anti-seizing properties, extending the service life of pumps operating in harsh environments.

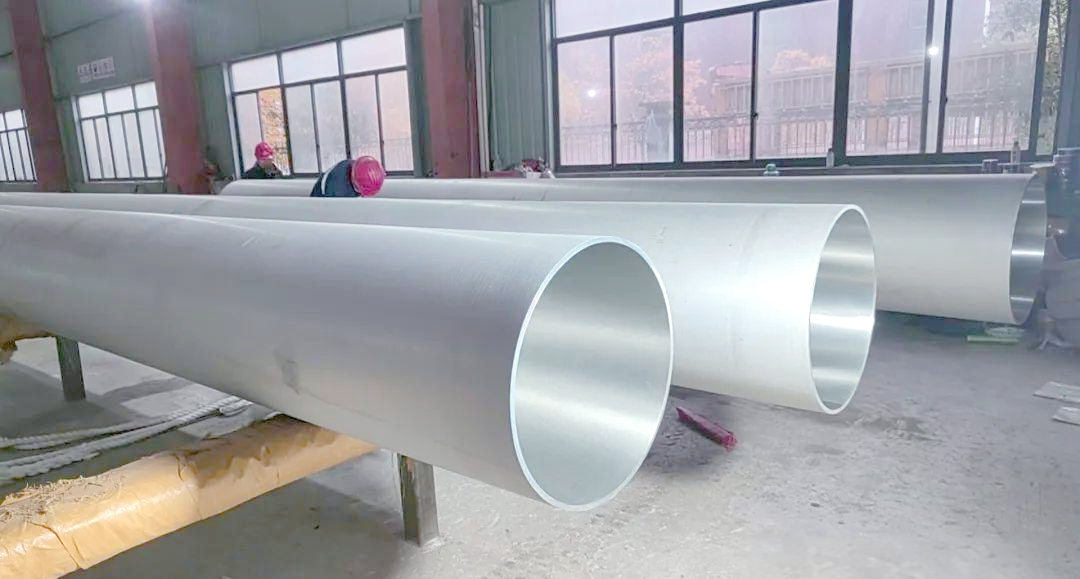

- High-temperature Piping: Components in furnaces and kilns require extremely high strength and can be used for critical stainless steel piping components.

- High-Wear Surfaces: It can be applied as a hardfacing layer to protect vulnerable components.

Sourcing and Processing of CO50 Alloy

A complete Material Test Report (MTR) is required. It verifies the precise composition of the alloy and ensures its performance.

Travailler avec specialized suppliers of stainless steel pipe and fittings. They understand these alloy steels and can ensure proper fabrication and quality control,and are ISO 9001 et CE-PED certified.

This alloy is difficult to machine and requires special tools. Specific welding techniques are essential to ensure the integrity of the weld.

This alloy is expensive, so it is important to assess whether the product has a longer service life. This can justify its higher initial cost.

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/