Les ASME B16.5 standard is critical in the piping systems field,specifying the design and specifications for brides en acier inoxydable and flanged pipe fittings.This standard ensures compatibility and interchangeability of flanges across various industries.

What is ASME B16.5

It is a standard established by the American Society of Mechanical Engineers (ASME).It outlines the specifications for pipe flanges and raccords de tuyauterie en acier inoxydable.This standard plays a key role in ensuring the integrity of piping systems.

This document covers flanges with nominal pipe sizes ranging from ½ inch to 24 inches.

It contains dimension,tolerance,and material specifications.These standards ensure the flanges can withstand specific pressure and temperature conditions.

Key Elements of ASME B16.5

- Interchangeability and Compatibility of Flanges

- Pressure and Temperature Ratings

- Flanging Material Specifications

Ce que nous faisons

- Plaque

- Feuille

- Forgeage

- Barre ronde

- Bride

- Tuyaux

- Raccords

- Sur mesure

Contactez-nous pour plus d'informations

Scope and Applications of ASME B16.5 Flanges

ASME B16.5 applies to pipe flanges and fittings worldwide.This includes but is not limited to:

- Pétrole et gaz

- Traitement chimique

- Production d'électricité

Flanges are essential for connecting pipes,valves,and other components in piping systems.They maintain system integrity and effectively prevent leaks and failures.Engineers highly value this standard for simplifying installation and maintenance processes while ensuring reliable equipment operation.

ASME B16.5 Flange Pressure Ratings

- Class 150

- Class 300

- Class 600

- Class 900

- Class 1500

- Class 2500

Key Specifications and Dimensions

ASME B16.5 applies to flanges with nominal diameters ranging from ½ inch to 24 inches.Each specification includes specific dimensions tailored to meet industry requirements.This standardization simplifies design and procurement processes across various sectors.

Pressure-temperature ratings form the core of the standard,defining the maximum pressure a flange can withstand at specific temperatures.Engineers select appropriate flanges for different operating conditions based on these ratings.

ASME B16.5 Flange Critical Dimensions

- Flange Diameter

- Bolt Hole Diameter and Pitch

- Flange Thickness

- Raised Face Height

Materials and Flange Types

ASME B16.5 specifies key materials affecting flange performance.Different materials suit varying environmental and pressure conditions.Selection must balance strength and corrosion resistance.

Common flange materials include acier au carbone,acier inoxydable et alloy steel.

- Carbon steel is economical for routine applications

- Stainless steel offers superior corrosion resistance

- Alloy steel provides high strength for demanding service conditions

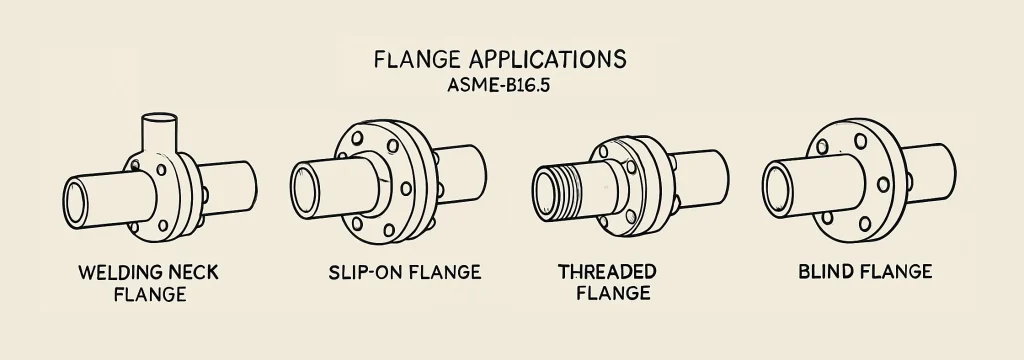

Types de brides

Flange Face Types and Markings

The face type of a flange affects its sealing abilities. ASME B16.5 outlines several face types to match different gasket materials. Picking the right face is key for preventing leaks.

- Raised face

- Flat face

- Ring-type joint

Testing, Quality, and Compliance with ASME Standards

Testing is a crucial aspect of ASME B16.5 flanges to assure safety and performance. Rigorous testing protocols exist to verify flange durability and resistance. Proper testing ensures flanges meet the demands of various environments.

Quality checks involve several steps that confirm flange integrity:

- Dimensional inspection

- Material verification

- Pressure tests

Why ASME B16.5 Matters in Industry

ASME B16.5 plays a vital role in various industries. It ensures the safe and efficient operation of piping systems. Its specifications prevent failures in high-pressure and high-temperature conditions.

Key reasons for its significance include:

- Ensures compatibility and interchangeability

- Reduces the risk of leaks and failures

- Promotes safety and reliability in design

Adhering to ASME B16.5 is essential for maintaining the integrity of industrial systems. It aids engineers in designing and analyzing piping frameworks effectively. This standard fosters confidence among manufacturers and end-users by guaranteeing quality and performance in their operations.

Vous voudrez peut-être aussi lire :

Qualité garantie : ISO 9001 et CE-PED pour un acier inoxydable irréprochable !

Qu'est-ce que la norme ISO 9001 2015 ? ?

CE-PED : Accès au marché de l'UE.

Stérilité du système principal avec connaissance du CIP et du SIP

ASME B16.5 en ingénierie

Bride ASME/ANSI B16.5-1996 et B16.47-1996

Qu'est-ce que l'ASME BPE : Votre guide vers l'excellence en matière de bioprocédés !

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/