Acier inoxydable VS Acier au carbone est un choix fondamental pour le système de tuyauterie, il affecte les performances, le coût et la durée de vie.Les deux matériaux sont largement utilisés et répondent à des objectifs différents. Il est essentiel de comprendre leurs propriétés uniques. tuyau en acier inoxydable et le fournisseur de raccords vous aide à prendre votre décision.

Acier inoxydable VS acier au carbone : différence fondamentale

La principale différence réside dans la teneur en chrome, l'acier inoxydable contenant au minimum 10,5% de chrome. Cet élément forme une fine couche passive. Cette couche empêche la rouille et la corrosion. L'acier au carbone est dépourvu de ce chrome. Il s'agit principalement d'un alliage de fer et de carbone, qui rouille donc facilement lorsqu'il est exposé à l'humidité. Cette différence essentielle détermine leurs applications.

Acier inoxydable VS acier au carbone : avantages et inconvénients

L'acier inoxydable présente une résistance supérieure à la corrosion. La couche d'oxyde de chrome le protège. L'acier au carbone rouille rapidement sans couche protectrice. L'acier inoxydable est donc idéal pour les environnements humides ou corrosifs.

L'acier au carbone est généralement plus abordable. Il offre une bonne résistance. L'acier inoxydable est plus cher. Cela est dû à sa teneur en chrome et en nickel. Pour de nombreuses applications structurelles, l'acier au carbone est un choix rentable.

L'acier inoxydable nécessite moins d'entretien. Sa résistance à la corrosion lui confère une durée de vie plus longue. L'acier au carbone nécessite des revêtements protecteurs. Ces revêtements doivent être réappliqués. Cela augmente les coûts d'entretien à long terme.

Les deux sont soudables. L'acier au carbone est généralement plus facile à souder. L'acier inoxydable nécessite des techniques spécifiques. Cela est dû à ses éléments d'alliage. Cela peut avoir une incidence sur les coûts et la rapidité de fabrication.

Acier inoxydable VS acier au carbone : propriétés clés

| Fonctionnalité | Acier inoxydable | Acier Carbone |

|---|---|---|

| Résistance à la corrosion | Excellent | Mauvais (sans revêtement) |

| Coût | Haut | Faible |

| Force | Bon à très élevé | Très élevé |

| Soudabilité | Bon (avec un soin particulier) | Excellent |

| Apparition | Brillant, propre, esthétique | Terne, nécessite un revêtement |

Ce que nous faisons

- Tuyaux >

- Raccords >

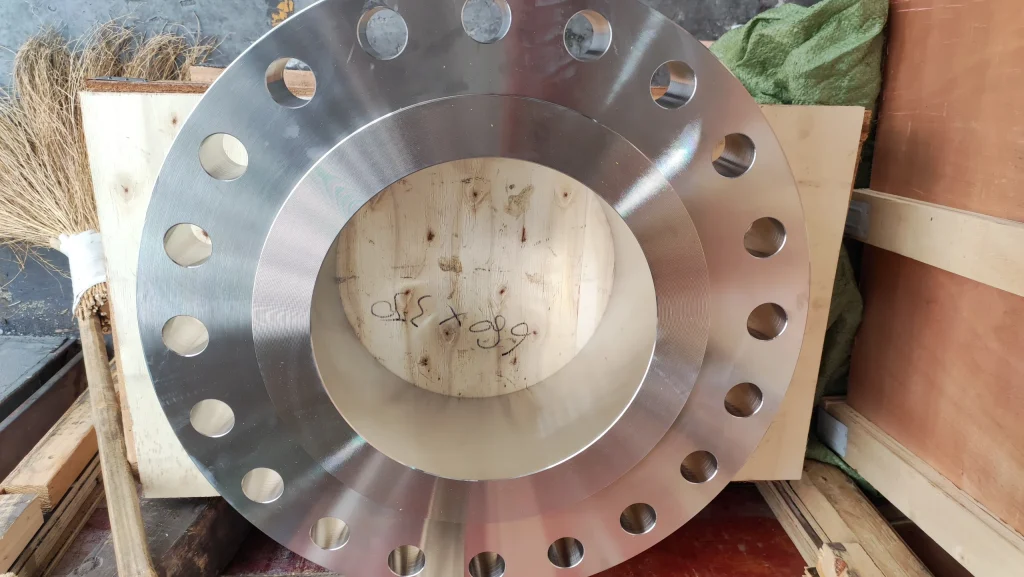

- Brides >

- Plus >

Acier inoxydable VS acier au carbone : applications

| Type d'application | Acier inoxydable préféré | Acier au carbone préféré |

|---|---|---|

| Environnements corrosifs | Traitement chimique, alimentation, marine | Non recommandé (sauf s'il est enduit) |

| Utilitaires généraux | Eau ultra-pure, gaz médicaux | Eau, huile, gaz (non corrosif) |

| Structurel | Architectural, décoratif, extérieur | Bâtiments, machines lourdes, charpentes |

| Températures élevées | Fours, échangeurs de chaleur | Centrales électriques, conduites de vapeur |

| Projets sensibles aux coûts | Lorsque la corrosion est un facteur | Lorsque le coût est le facteur principal |

Nuances courantes d'acier inoxydable

| Grade | Caractéristiques principales | Avantage principal | Cas d'utilisation typique |

|---|---|---|---|

| 304/304L | Alliage standard | Rentable, bonne résistance à la rouille | Services publics généraux, alimentation |

| 316/316L | Molybdène ajouté | Résistance aux chlorures, pas de piqûres | Marine, chimie, pharmacie |

| 310S | Haute teneur en Cr/Ni | Excellente résistance aux températures élevées | Pièces de fournaise, échangeurs |

| 2205 (Duplex) | Ferritique-austénitique | Haute résistance, résistant à la corrosion sous contrainte | Offshore, service acide |

| 321 | Stabilisé au titane | Résiste à la détérioration des soudures | Échappement haute température |

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/