Molybdenum in stainless steel can be helpful in aggressive conditions. It transforms ordinary steel into a high-performance alloy that ensures tuyaux en acier inoxydable et raccords are built to last.

What Is Molybdenum in Stainless Steel? A Game Changer!

Molybdenum in stainless steel is a powerful alloying element that greatly enhances performance. It mainly enhances corrosion resistance and increases strength at high temperatures. In specialised steel grades, molybdenum is usually present in amounts of between 2 and 7%. This small addition makes a big difference.

Key Benefits of Molybdenum in Stainless Steel

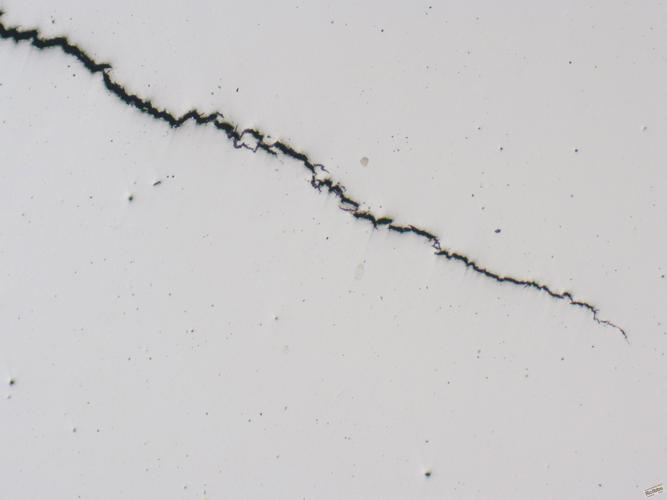

Molybdenum stabilises the passive layer, making it more resistant to chloride attack, which greatly reduces the likelihood of pitting. This is critical for seawater or chemical applications.

It prevents localised corrosion in tight spaces. Molybdenum helps maintain passivation. It resists corrosion where oxygen is limited. This is critical for flanges and fittings.

Molybdenum improves high-temperature strength and prevents creep distortion. This gives stainless steel reliable properties that excel in high-temperature processing.

Molybdenum improves resistance to stress corrosion cracking. It alters the passive film, which makes the material more resistant to stress. This improves the safety of critical systems.

Molybdenum enhances resistance to a wide range of chemicals, including sulphuric, phosphoric and organic acids. This makes the material versatile and suitable for a wide range of industrial piping.

Molybdenum's Role in Stainless Steel

| Role | Mechanism | Effect on Stainless Steel |

|---|---|---|

| Passive Layer Enhancer | Forms stable molybdenum oxides | Boosts corrosion resistance |

| Chloride Blocker | Competes with chlorides | Resists pitting |

| Solution Strengthener | Solid solution hardening | Improves high-temp strength |

| Carbide Former | Forms beneficial carbides | Refines microstructure |

| Hydrogen Embrittlement | Can influence resistance | Complex interaction |

Ce que nous faisons

Molybdenum-Containing Stainless Steel Grades

| Grade | Molybdenum (%) | Primary Application Areas |

|---|---|---|

| 316 / 316L | 2.0 – 3.0 | Marine, chemical, food processing, medical |

| 317L | 3.0 – 4.0 | Pulp & paper, chemical plants, condensers |

| Duplex (e.g., 2205) | 2.5 – 3.5 | Offshore, chemical tankers, structural |

| Super Duplex (e.g., 2507) | 3.5 – 5.0 | Seawater systems, highly corrosive environments |

| 6% Mo Super Aust. (e.g., 254SMO) | 6.0 – 7.0 | Flue gas desulfurization, bleaching, offshore |

| Hastelloy / Inconel | 8.0 – 18.0 | Extreme acids, high-temp chemical processing |

Molybdenum in Stainless Steel Pipe and Fittings Applications

- Chemical Treatment: Pipes and fittings can handle aggressive acids. Molybdenum has important corrosion resistance and ensures a long service life.

- Marine And Offshore: Seawater systems require high resistance to pitting, and molybdenum-rich grades are resistant to chlorides.

- Pulp And Paper Industry: Bleaching plants use highly corrosive chemicals, which are resisted by molybdenum-rich stainless steels.

- Pharmaceutical Industry: High purity and corrosion resistance are essential. Molybdenum-containing steels resist aggressive cleaning solutions.

- Heat Exchangers: Pipes and tubes operate at high temperatures. Molybdenum increases strength and also resists corrosion from process fluids.

Sourcing Molybdenum-Rich Stainless Steel

Choose a manufacturer who has extensive experience with stainless steel and who understands its unique properties. This ensures optimal moulding results.

Look for state-of-the-art tooling capabilities, precision tooling is critical and can affect part quality and consistency.

Ensure rigorous qualité checks are in place, including dimensional checks, etc. Material integrity verification and material test reports are also critical.

Work with reputable manufacturers who offer reliable stainless steel products and have certifications(e.g. ISO 9001 and CE-PED).

Confirm that the manufacturer can meet your production volume requirements. They should handle both prototyping and volume production.

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/