Nimonic 75 est une solution fiable pour les températures extrêmes. La résistance à la chaleur de cet alliage haute performance est bien supérieure à celle des aciers inoxydables standard. Ses propriétés uniques sont essentielles à la durabilité à long terme. Choisir Nimonic 75, c'est s'assurer que vos pièces critiques tuyaux en acier inoxydable et raccords de tuyauterie en acier inoxydable maintenir leur force et leur fonctionnalité.

Nimonic 75 | UNS N06075

Nimonic 75 est un alliage à base de nickel appartenant au groupe Alliage Nimonicqui contient environ 20% chrome et présente donc une excellente résistance à l'oxydation. Il possède de bonnes propriétés mécaniques à haute température.

Ce que nous faisons

Principaux atouts de Nimonic 75

Nimonic 75 est résistant à l'oxydation et peut supporter des températures de fonctionnement continues allant jusqu'à 980°C (1795°F).

Il conserve sa résistance à des températures élevées pour des performances fiables. Il n'est pas conçu pour résister déformation par fluage. Cependant, il présente une bonne intégrité mécanique dans de nombreuses applications.

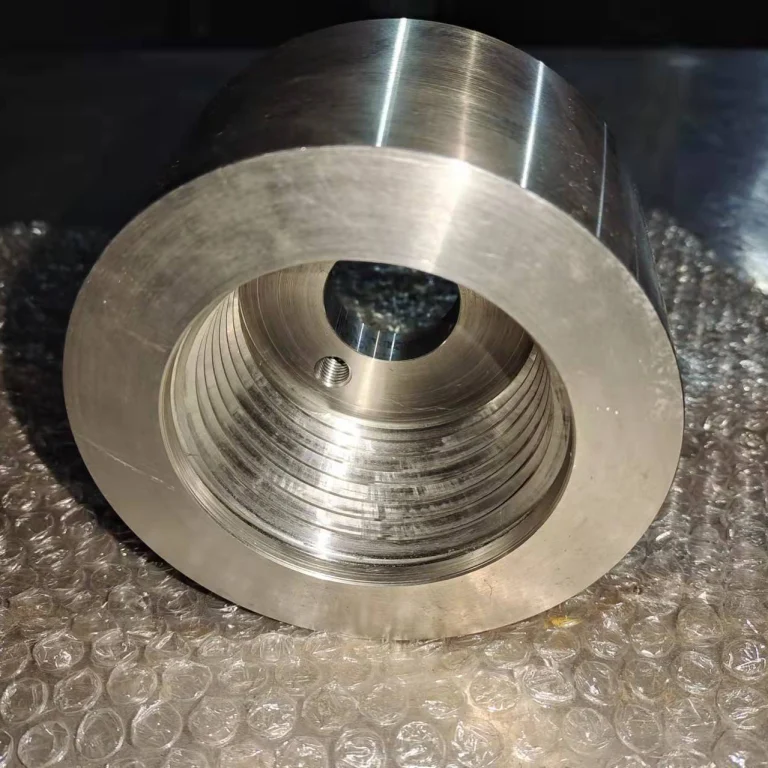

Nimonic 75 est facile à mouler, facile à souder et supporte bien les fabrications complexes.

Il conserve ses propriétés lorsqu'il est soumis à la chaleur et ne perd pas rapidement sa résistance, ce qui le rend idéal pour les applications à haute température.

Composition chimique

| Élément | Ni | Cr | Fe | C | Ti | Cu | Mn | Si |

|---|---|---|---|---|---|---|---|---|

| Contenu (wt%) | Équilibre | 18.0-21.0 | 5.0 Max | 0.08-0.15 | 0.20-0.60 | 0,5 Max | 1.0 Max | 1.0 Max |

Propriétés mécaniques

| Biens | Résistance à la traction | Limite d'élasticité (décalage de 0,2%) | Élongation | Dureté | Densité | Plage de fusion |

|---|---|---|---|---|---|---|

| Valeur (typique) | ≥690MPa(100ksi) | ≥275MPa(40ksi) | ≥30 | 200 Max | 8,26g/cm³ | 1370-1420 ℃ |

Nimonic 75 dans les systèmes de tuyauterie à haute température

- Tubes à flamme : Ils peuvent résister à une chaleur élevée et être utilisés pour les tubes à flamme.

- Systèmes d'échappement : Ils supportent les flux de gaz chauds, résistent à l'oxydation et à la corrosion et peuvent être utilisés dans les collecteurs d'échappement.

- Tubes et soufflets : Ces matériaux peuvent résister aux cycles thermiques et sont utilisés pour fabriquer des tuyaux à haute température et des soufflets de dilatation.

- Composants de four : Résiste à des températures élevées soutenues et prévient l'entartrage pour les revêtements de fours et les carénages.

- Systèmes de tuyauterie : Ils peuvent être utilisés pour les raccords critiques en acier inoxydable lorsqu'une résistance extrême à la chaleur est requise.

Approvisionnement et fabrication de Nimonic 75

Un complet Rapport d'essai des matériaux (MTR) est nécessaire. Il vérifie la composition précise de l'alliage et garantit ses performances.

Travailler avec fournisseurs spécialisés de tubes et raccords en acier inoxydable. Ils connaissent ces aciers alliés et peuvent garantir une fabrication et un contrôle de qualité adéquats. ISO 9001 et CE-PED certifié.

Il est difficile à usiner et nécessite des outils spéciaux. Des techniques de soudage spécifiques sont indispensables pour garantir l'intégrité de la soudure.

Il est coûteux, il est donc important d'évaluer si le produit a une durée de vie plus longue. Cela peut justifier son coût initial plus élevé.

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/