The magnetic properties of stainless steel depend on the type and composition of the steel.Some stainless steels are magnetic,while others are not.

To understand this phenomenon,one must delve into the structure of the material.Different types of stainless steel exhibit distinct magnetic characteristics.

What Makes Steel and Stainless Steel Magnetic?

Ce que nous faisons

- Plaque

- Feuille

- Forgeage

- Barre ronde

- Bride

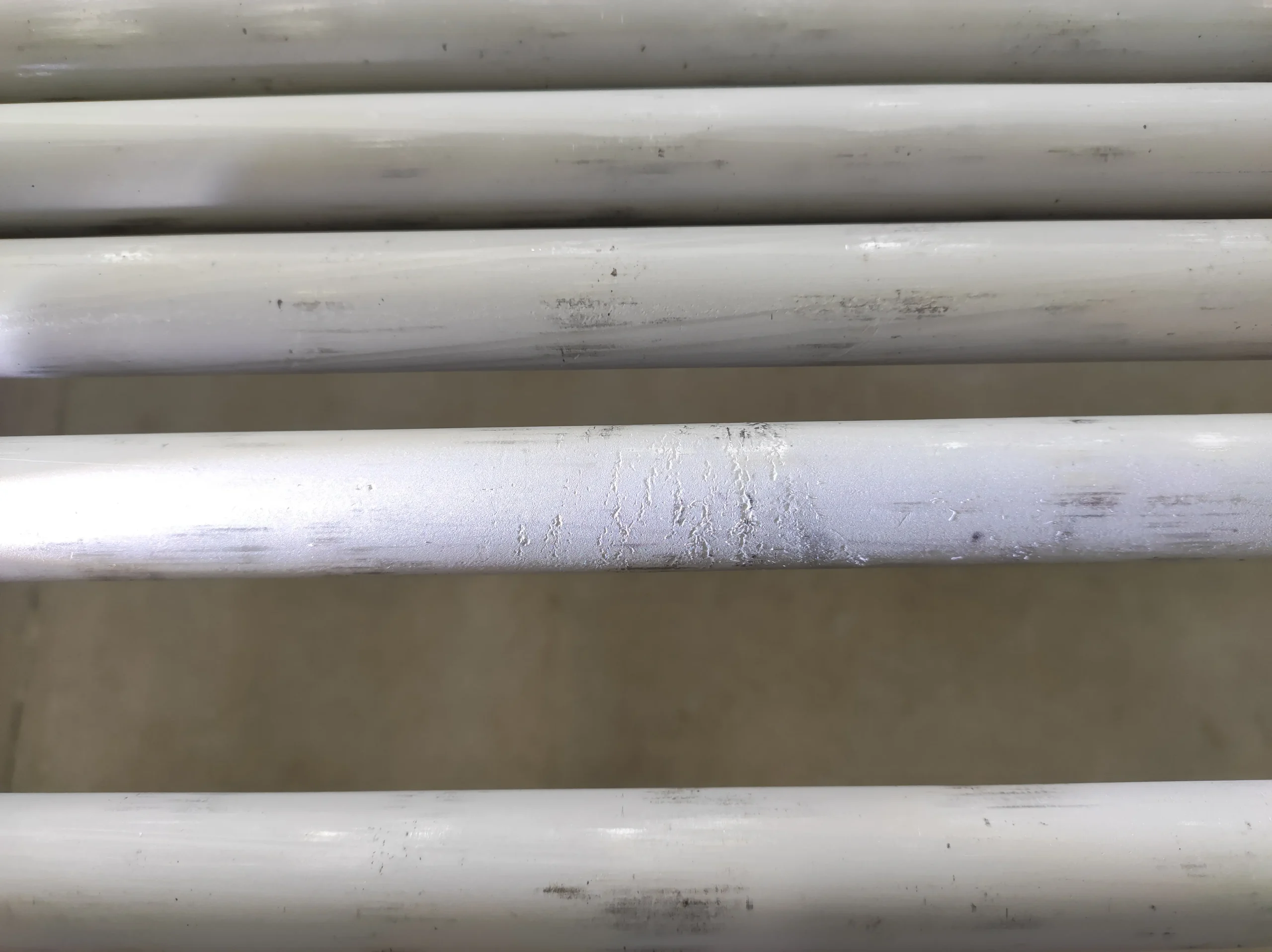

- Tuyaux

- Raccords

- Sur mesure

Contactez-nous pour plus d'informations

Types of Stainless Steel and Their Magnetic Properties

Austenitic Stainless Steels: Mostly Non-Magnetic

Aciers inoxydables austénitiques, tels que Acier 304 et Acier 316, are widely used. They are primarily non-magnetic due to their face-centered cubic (FCC) structure.

The presence of nickel in their composition disrupts the iron atom alignment. This disruption reduces their magnetic properties significantly.

Despite being mostly non-magnetic, some austenitic steels can become slightly magnetic. Cold working can induce a small degree of magnetism in these materials.

Ferritic and Martensitic Stainless Steels: Magnetic Types

Ferritic stainless steels, such as type 430, are magnetic. This is due to their body-centered cubic (BCC) crystal structure.

Martensitic stainless steels are also magnetic. They can be hardened by heat treatment, making them suitable for tools and knives.

Both ferritic and martensitic steels are used where magnetic properties are beneficial. Their applications span from kitchen equipment to automotive parts.

Duplex and Precipitation-Hardening Stainless Steels

Duplex stainless steels have a mixed microstructure of austenite and ferrite. This gives them partially magnetic properties.

Precipitation-hardening stainless steels exhibit good strength and magnetic characteristics. They are used in aerospace and nuclear industries for their durability.

These types bridge the gap between non-magnetic and fully magnetic steels. Their unique properties cater to specialized needs, where both strength and magnetism are required.

Factors That Influence Magnetism in Stainless Steel

Several factors affect the magnetism of stainless steel. Each plays a role in determining whether the steel will be magnetic or not.

One major factor is the steel’s composition chimique. The presence of elements like nickel can reduce magnetism.

Les processus de fabrication also influences magnetism. Cold working can increase the magnetic properties of non-magnetic steels.

- Chemical composition: Presence of nickel and chrome.

- Microstructure: Determines magnetic properties.

- Processing methods: Cold working, heat treatment.

Why Does Magnetism Matter?

Magnetic properties determine if a material is suitable for specific uses. These considerations can impact performance and efficiency.

In electronics, magnetic stainless steel is vital. It is used in sensors and magnetic separators. Non-magnetic types reduce interference, making them ideal for some devices.

Applications

- Medical devices: Require non-magnetic steel.

- Construction materials: Use magnetic types for stability.

- Electronic components: Depend on specific magnetic properties.

How to Test If Stainless Steel Is Magnetic

- Place a magnet on the steel surface.

- If it sticks, the steel is magnetic.

- If it doesn’t, the steel is likely non-magnetic.

Vous voudrez peut-être aussi lire :

L'acier inoxydable rouille-t-il ?

Does Stainless Steel Tarnish ?

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/