The Fundamental Chemistry Difference

Corrosion Resistance and Mechanical Strength

- Inconel 625 (The Corrosion Specialist):

This alloy is a true corrosion resistant alloy.It provides superior protection against pitting,crevice corrosion and high-temperature oxidation.Because it lacks the iron content of 718,it performs better in seawater and aggressive chemical processing.It is the go-to choice for thin-walled pipes and complex fittings. - Inconel 718 (The Strength Specialist):

This alloy focuses on high-load capacity.It maintains its incredible strength at temperatures up to 700°C (1300°F).In piping systems,engineers use 718 for heavy-duty bolts,high-pressure pump shafts and specialized flanges.If your system faces extreme mechanical tension,718 is the winner.

Ce que nous faisons

- Plaque

- Feuille

- Forgeage

- Barre ronde

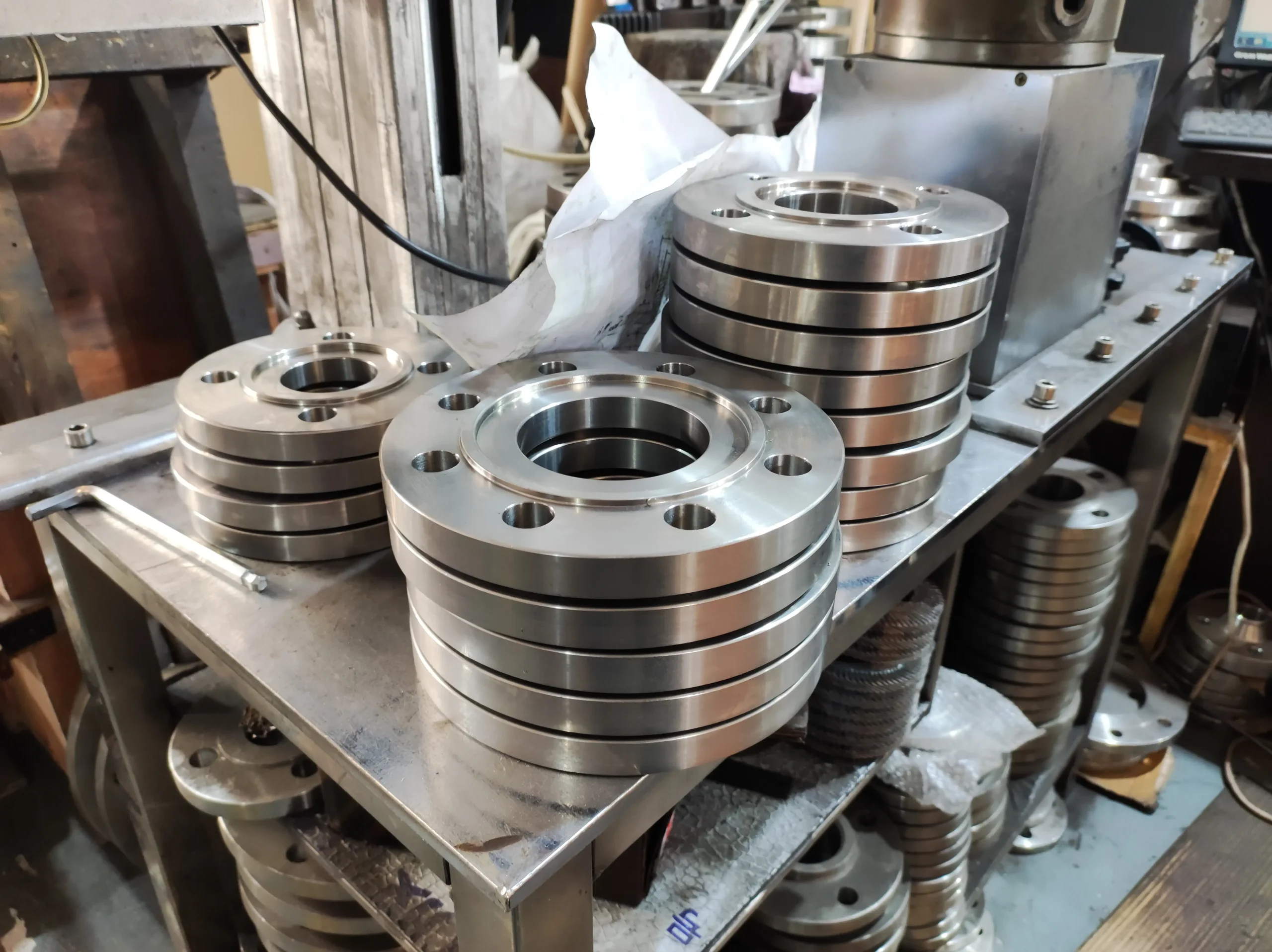

- Bride

- Tuyaux

- Raccords

- Sur mesure

Contactez-nous pour plus d'informations

Comparing Technical Specifications

| Biens | Inconel 625 | Inconel 718 |

|---|---|---|

| Strengthening Method | Solid Solution | Precipitation Hardening |

| Tensile Strength (Typical) | 800 – 1000 MPa | 1200 – 1400 MPa |

| Yield Strength (Typical) | 400 – 600 MPa | 1000 – 1100 MPa |

| Max Service Temp (Strength) | ~ 650°C | ~ 700°C |

| Résistance à la corrosion | Excellent (especially marine) | Very Good (less than 625) |

| Soudabilité | Outstanding | Good (requires care) |

Applications of Inconel 625 and 718

Pipes and Fittings

Flanges and Bolting

Welding and Fabrication Considerations

Material Composition Comparison

| Élément | Ni | Cr | Fe | Nb | Mo | Ti |

|---|---|---|---|---|---|---|

| Inconel 625 | 58 Min | 20 – 23 | 5 Max | 3.15 – 4.15 | 8 – 10 | 0.4 Max |

| Inconel 718 | 50 – 55 | 17 – 21 | ~ 17 | 4.75 – 5.5 | 2.8 – 3.3 | 0.65 – 1.15 |

Inconel 625 vs 718:Cost and Machinability

Due to its significantly higher hardness,Inconel 718 causes greater wear on CNC machine tools and cutting tools.Consequently,the machining cost for Inconel 718 flanges is typically higher than that for equivalent 625 flanges.

Additionally,the material’s toughness necessitates reduced cutting speeds.If your project has a tight budget and moderate pressure requirements,Inconel 625 may be a more attractive choice for standard piping components.

Fatigue Life and Creep Performance

Inconel 718 exhibits exceptional fatigue strength,withstanding millions of pressure cycles without microcracking.It is suitable for complex manifolds in piping networks and high-vibration pump housings.

Although Inconel 625 exhibits toughness,it is more susceptible to progressive deformation (creep) after thousands of hours at its upper temperature limit.For dynamically loaded components,718 remains the industry standard choice.

Heat Treatment Protocols for Inconel 625 and 718

- Inconel 625:

Requires only simple solution annealing.This process restores the protective passivation layer and prepares the material for use,representing a relatively quick and straightforward procedure. - Inconel 718:

Requires a multi-stage “age hardening” treatment.This process involves heating the metal and holding it at specific temperatures for several hours.This precise control facilitates the formation of precipitates that impart strength to the alloy.Due to the extended duration of this process,delivery lead times for 718 tubing are typically longer.

Choosing between Inconel 625 and 718 depends on your primary engineering objectives.For piping systems exposed to highly corrosive acids or seawater environments,Inconel 625 is the preferred option.Its machinability and exceptional passivation layer stability ensure long-term reliability.

However,if mechanical load-bearing capacity and high-temperature creep resistance are your primary concerns,Inconel 718 represents a wiser investment.It provides the strength support required for flanges and high-stress components.

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/