Hastelloy G est une famille d'alliages de nickel-chrome-fer-molybdène.Il offre une superbe résistance à la corrosion dans une large gamme d'environnements chimiques.Un choix de premier ordre se dessine pour les applications où les alliages standard de nickel-chrome-fer-molybdène sont utilisés. tuyaux en acier inoxydable ou raccords de tuyauterie en acier inoxydable échouerait.

Introduction à la série Hastelloy G

La série Hastelloy G est un groupe spécialisé d'alliages dont les éléments clés sont le nickel, le chrome, le fer et le molybdène. Ces alliages fonctionnent bien dans les environnements oxydants et réducteurs. Le cuivre est également présent, ce qui améliore la résistance aux acides sulfurique et phosphorique.

Qu'est-ce que l'alliage Hastelloy ?

L'alliage Hastelloy contient une forte proportion de nickel, ainsi que du chrome et du molybdène. La famille comprend trois séries principales. Il s'agit de la série B, de la série C et de la série G. Chacune est conçue pour des environnements spécifiques.

Ce que nous faisons

- Plaque

- Feuille

- Forgeage

- Barre ronde

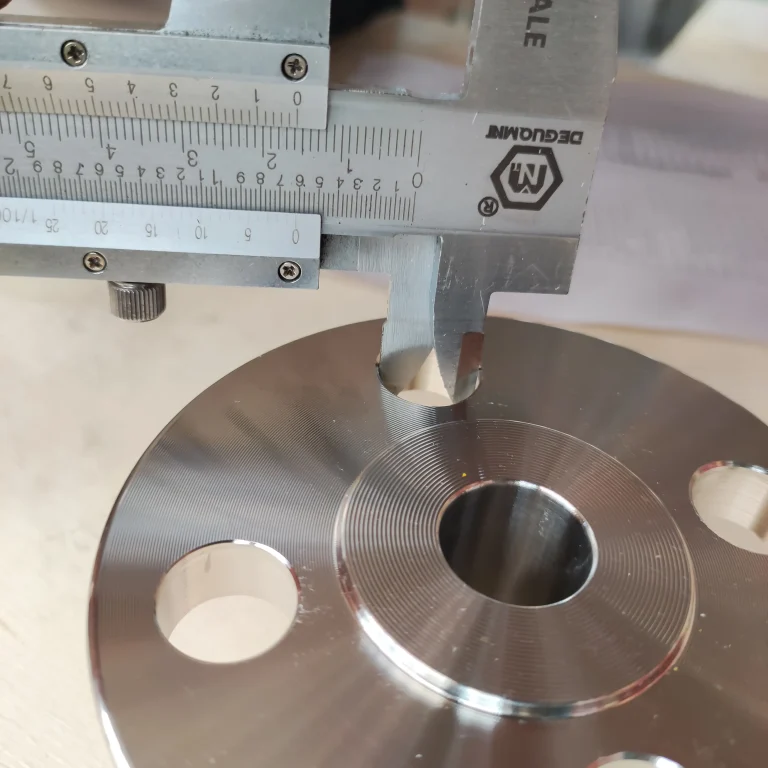

- Bride

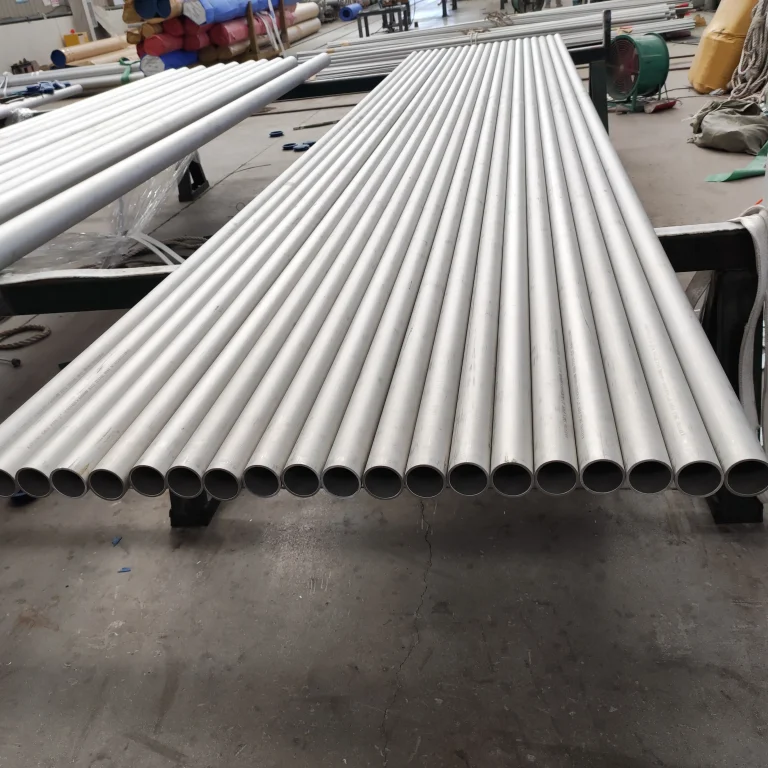

- Tuyaux

- Raccords

- Sur mesure

Contactez-nous pour plus d'informations

Principaux avantages de la série Hastelloy G

Cet alliage supporte bien les mélanges d'acides. La résistance aux milieux oxydants et réducteurs est un avantage clé. Les performances supérieures sont obtenues contre les acides sulfuriques et phosphoriques.

La composition de l'alliage permet de lutter activement contre la corrosion par piqûres et la corrosion caverneuse. C'est pourquoi il constitue souvent une meilleure option que de nombreux aciers inoxydables.

La facilité de fabrication est un avantage majeur. Des soudures solides sont réalisées sans perte de propriétés. Les tuyaux et raccords complexes sont ainsi plus simples à créer.

Une faible teneur en carbone empêche la sensibilisation après le soudage. L'alliage conserve ainsi sa résistance à la corrosion. Le matériau se comporte bien dans la zone affectée thermiquement.

Principaux inconvénients de la série Hastelloy G

La composition contient du nickel et du molybdène coûteux, dont l'ajout fait grimper le prix.

Ce matériau d'alliage a une densité élevée, ce qui augmente le poids du système. Ses caractéristiques de haute densité doivent être prises en compte lors de la conception et de la planification de la structure de support.

Une dureté élevée entraîne des difficultés d'usinage, nécessitant des outils et des vitesses d'usinage spécialisés, ce qui augmente le temps et les coûts de fabrication.

L'alliage présente une bonne résistance aux températures élevées. Toutefois, il ne constitue pas un choix prioritaire pour les applications à haute résistance et à haute température. L'alliage ne possède pas les propriétés d'autres superalliages pour une utilisation structurelle à haute température.

Processus de dégradation naturelle de l'Hastelloy G

- Fluage et rupture sous contrainte : Des températures élevées et des contraintes soutenues peuvent entraîner une déformation lente et permanente appelée fluage. Avec le temps, cette déformation peut aboutir à une défaillance. La résistance de l'alliage diminue progressivement avec une exposition prolongée.

- Fatigue : Des cycles de contrainte répétés peuvent induire des microfissures dans les composants. Ces fissures se propagent progressivement et finissent par provoquer la défaillance du composant.

- Corrosion à long terme : Malgré une résistance élevée à la corrosion, une exposition prolongée à des produits chimiques hautement corrosifs peut dégrader le matériau. Au fil du temps, une corrosion par piqûres ou un amincissement de la surface peut se produire. Bien qu'extrêmement lent, ce processus est un phénomène naturel dans le cycle de vie de l'alliage.

- Érosion-Corrosion : Les environnements impliquant un écoulement de fluide à grande vitesse induisent une forme spécifique de dégradation. Les effets combinés de l'érosion et de la corrosion usent continuellement l'alliage, réduisant potentiellement sa durée de vie dans certaines applications.

Grades communs d'Hastelloy G

| Grade | Éléments clés | Avantage principal |

|---|---|---|

| Hastelloy G3 | Cr/Fe/Mo | Se soude facilement, résiste aux piqûres |

| Hastelloy G30 | Cr/Fe/Mo | Résistance à l'acide phosphorique |

| Hastelloy G35 | Cr/Fe/Mo | Haute résistance, résiste à l'attaque des chlorures |

| Hastelloy G50 | Cr/Fe/Mo | Bon pour l'acide sulfurique à haute température |

Hastelloy G VS Acier inoxydable

| Caractéristique | Hastelloy G | Acier inoxydable |

|---|---|---|

| Acides mixtes | Excellent | Pauvre |

| Corrosion par piqûres et crevasses | Excellent | Bon |

| Résistance aux chlorures | Excellent | Bon |

| Coût | Très élevé | Moyen |

| Utilisation principale | Environnements acides phosphoriques | Résistance générale à la corrosion |

Série Hastelloy G dans les systèmes de tuyauterie

- Traitement chimique : Hastelloy G offre une résistance extrême à la corrosion pour les raccords de tuyauterie critiques en acier inoxydable. Votre système fonctionne parfaitement, même avec des mélanges d'acides agressifs.

- Production d'engrais : L'alliage est parfait pour la manipulation de l'acide phosphorique en voie humide. Il résiste aux produits chimiques hautement corrosifs. Son utilisation garantit un fonctionnement efficace et sûr.

- Désulfuration des gaz de combustion : Une utilisation clé de cet alliage. Il résiste aux environnements corrosifs que l'on trouve dans les centrales électriques. Sa haute résistance protège les tuyaux et les raccords.

- Traitement des déchets : Ce matériau est essentiel pour les tuyaux et les raccords dans le traitement des déchets. L'Hastelloy G supporte les produits chimiques corrosifs. L'alliage conserve son intégrité. Cela permet d'éviter les fuites et les temps d'arrêt coûteux.

Approvisionnement et fabrication d'alliages Hastelloy

Un rapport complet d'essai des matériaux (MTR) est nécessaire. Il vérifie la composition précise de l'alliage et garantit ses performances.

Travailler avec fournisseurs spécialisés de tuyaux et de raccords en acier inoxydable. Ils connaissent ces aciers alliés et peuvent garantir une fabrication et un contrôle de qualité adéquats. Ils sont certifiés ISO 9001 et CE-PED.

Cet alliage nécessite des procédures spécifiques. Une technique de soudage appropriée garantit l'intégrité de la soudure.

Il est coûteux, il est donc important d'évaluer si le produit a une durée de vie plus longue. Cela peut justifier son coût initial plus élevé.

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/