Qu'est-ce que la rouille des brides ?

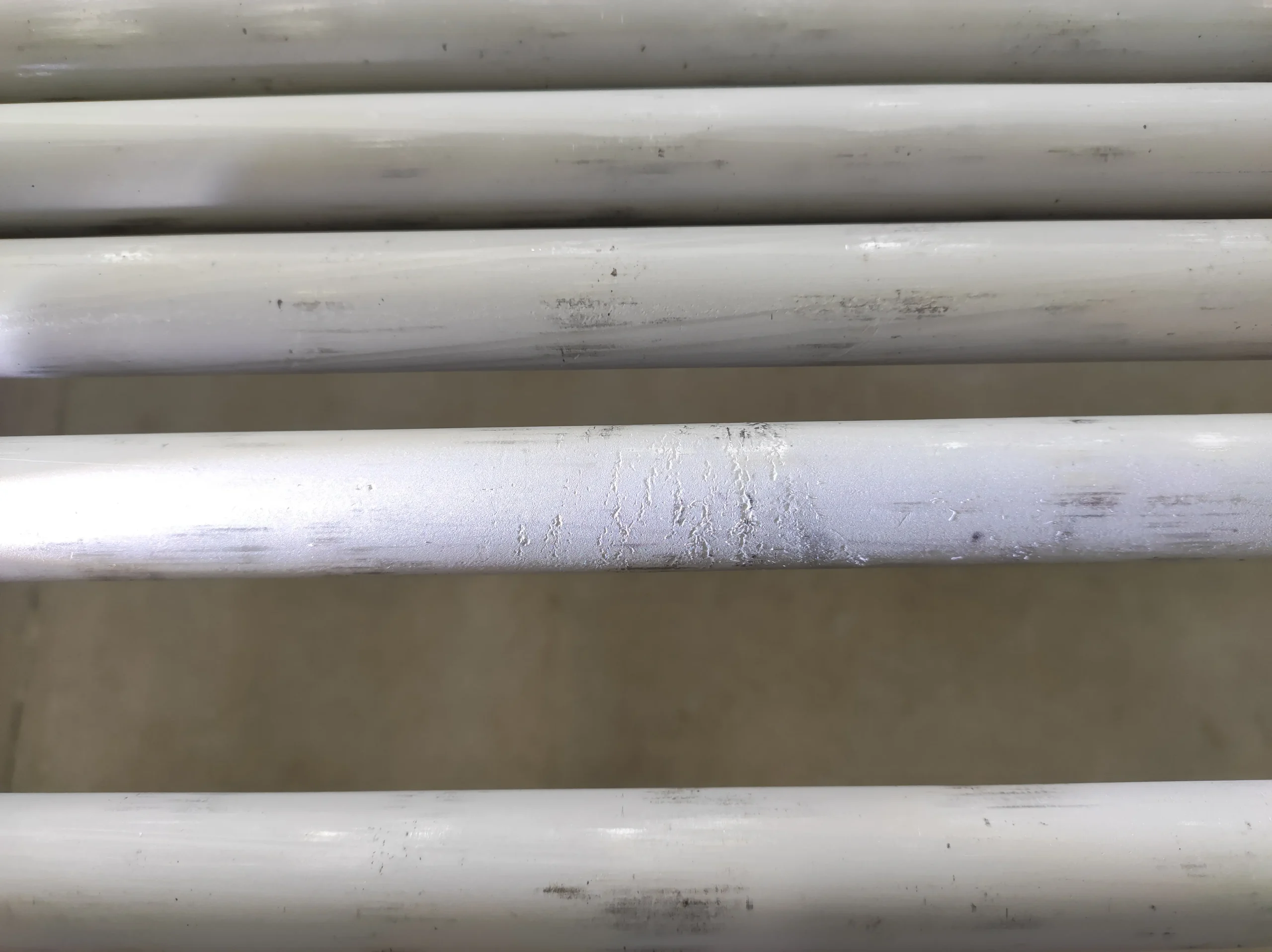

Rouille de la bride est un problème sérieux dans de nombreux systèmes industriels. Il a un impact direct sur la sécurité et l'efficacité des réseaux de tuyauterie. brides en acier inoxydable Ceci est vrai pour les systèmes utilisant des tuyaux en acier inoxydable et raccords de tuyauterie en acier inoxydableLa première étape consiste à comprendre pourquoi la corrosion se produit. Le choix d'un matériau approprié est essentiel pour prévenir la défaillance des brides.

Qu'est-ce qu'une bride ?

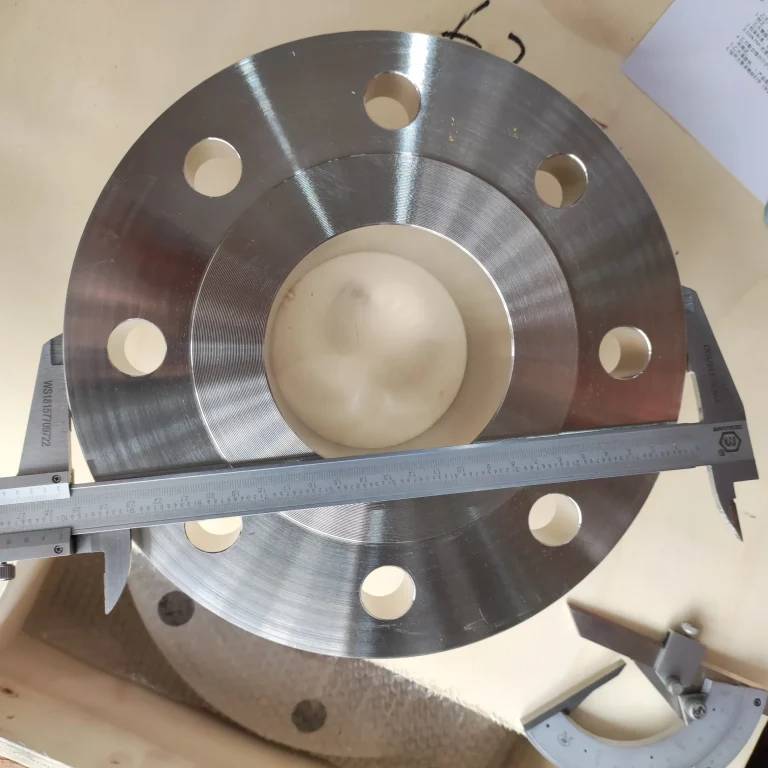

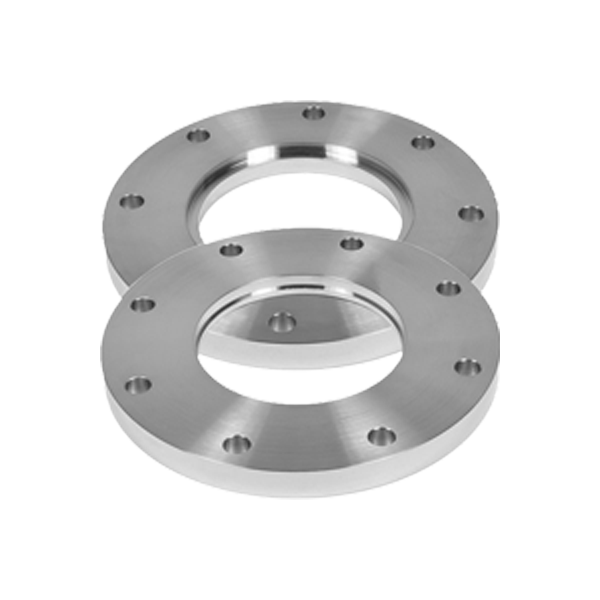

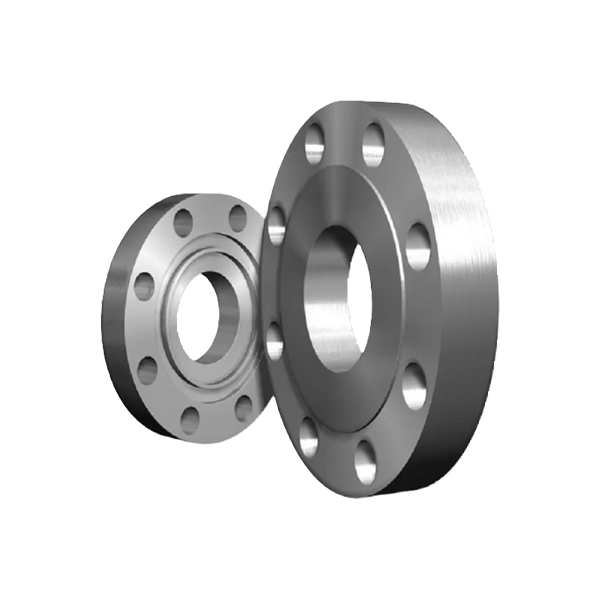

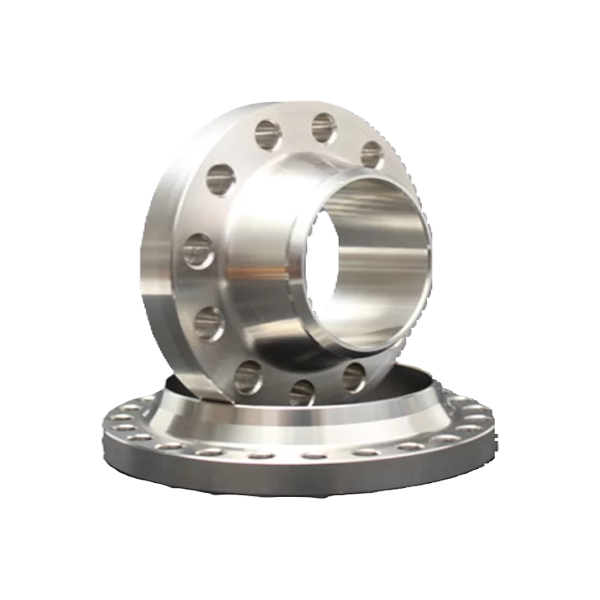

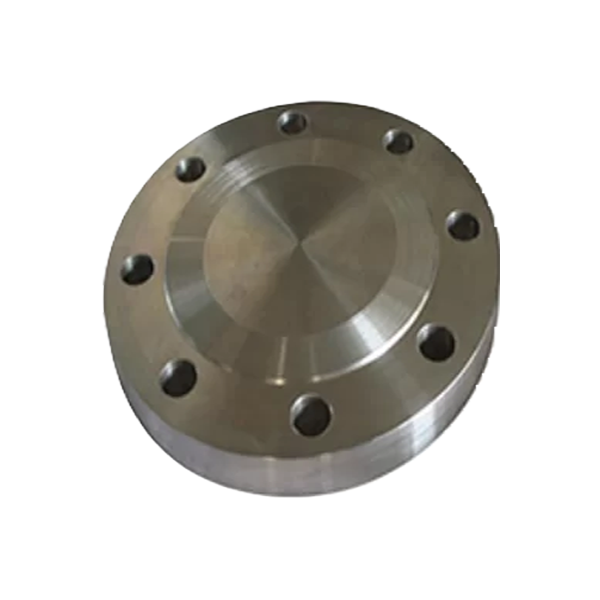

Qu'est-ce qu'une bride ? Les brides sont un type de raccordement utilisé pour joindre des tuyaux,vanneset d'autres équipements. Ils forment un joint sûr et étanche et sont largement utilisés dans de nombreuses industries. Cette méthode de connexion est à la fois sûre et fiable, tout en facilitant le démontage.Brides sont fabriqués à partir de divers matériaux sélectionnés pour leur solidité et leur résistance à la corrosion.

Ce que nous faisons

Principaux inconvénients de la rouille des brides

La rouille des brides peut provoquer piqûre Cela réduit la capacité de la bride à supporter la pression et peut donc entraîner des défaillances soudaines. Une bride affaiblie constitue un risque sérieux pour la sécurité.

La rouille des brides dégrade la surface d'étanchéité. Cela crée des voies d'accès pour les fuites. Les fuites de fluides de traitement peuvent être dangereuses. Elles présentent des risques pour l'environnement et la sécurité. Cette contamination entraîne également une inefficacité du système.

Les effets de la rouille sur les brides conduisent à des inspections plus fréquentes. Ils nécessitent des réparations coûteuses ou un remplacement complet. Il en résulte d'importants temps d'arrêt non planifiés. Ces coûts s'accumulent au fil du temps.

En fin de compte, la rouille des brides réduit la durée de vie de l'ensemble du système. Elle oblige à remplacer prématurément les composants. Cette corrosion peut s'étendre aux tuyaux de raccordement. L'ensemble du système peut nécessiter une révision complète. Cette opération est beaucoup plus coûteuse.

Choix des matériaux pour lutter contre la rouille des brides

Composition chimique par matériau

| Matériau | Fe | Cr | Ni | Mo | Autres éléments |

|---|---|---|---|---|---|

| Acier 304 | Bal. | 18.0 – 20.0 | 8.0 – 10.5 | – | C : ≤0.08, Si : ≤1.0, Mn : ≤2.0 |

| Acier 316L | Bal. | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | C : ≤0.03, Si : ≤1.0, Mn : ≤2.0 |

| Titane | Bal. | – | – | – | Ti : ≥99.2, N : ≤0.03, H : ≤0.015, Fe : ≤0.3, O : ≤0.25 |

| Aluminium | 0 - 0.7 | 0.04 – 0.35 | – | – | Al : Bal, Mg : 0.8-1.2, Si : 0.4-0.8, Cu : 0.15-0.4 |

Propriétés mécaniques par matériau

| Biens | Acier 304 | Acier 316L | Titane | Aluminium |

|---|---|---|---|---|

| Résistance à la traction (MPa) | ≥515 | ≥485 | ≥345 | ≥275 |

| Limite d'élasticité (décalage 0,2%) (MPa) | ≥205 | ≥170 | ≥275 | ≥240 |

| Élongation (%) | ≥40 | ≥40 | ≥20 | ≥10 |

Ce que nous faisons

Applications des brides dans les systèmes de tuyauterie

Dans ces systèmes, les brides sont confrontées à des acides et des produits chimiques extrêmement corrosifs.Acier inoxydable 316L est un choix populaire. teneur en molybdène Il est souvent utilisé pour les raccords de tuyauterie en acier inoxydable dans les usines chimiques.

Ces environnements ont une forte teneur en chlorure et l'eau de mer est très corrosive, bride en titane Ils offrent une résistance supérieure aux piqûres et à la corrosion. corrosion par crevassesCela garantit la fiabilité et la longévité du système.

Les La bride dans le pétrole et le gaz L'industrie pétrolière et gazière fonctionne sous des pressions et des températures extrêmes. Les brides doivent résister aux hydrocarbures corrosifs et aux conditions difficiles du fond de puits. Les alliages de haute qualité sont essentiels pour éviter la rouille des brides et les défaillances catastrophiques.

Pour les environnements moins agressifs,Acier inoxydable 304 Elles offrent un bon équilibre entre le coût et la résistance à la corrosion et conviennent à de nombreuses applications de tuyauterie en acier inoxydable.

A bride en aluminium Ils sont choisis pour leur légèreté et leur résistance modérée. Ils conviennent aux applications à basse pression. Le poids est une préoccupation majeure de la conception.

Comment prévenir la rouille des brides

- Choisir le bon matériau:C'est l'étape la plus importante.Sélectionnez un matériau de bride résistant à votre environnement de travail spécifique.Par exemple, utilisez de l'acier inoxydable 316L pour éviter la rouille de la bride dans des conditions marines.Pour les produits chimiques extrêmement agressifs, le titane est une meilleure option.

- Appliquer Revêtements protecteursLes revêtements créent une barrière qui sépare le matériau de la bride des éléments corrosifs. Des revêtements riches en zinc, des peintures ou des enveloppes anticorrosion spécialisées peuvent être appliqués. Il s'agit d'un moyen efficace d'arrêter la rouille sur les brides en acier au carbone.

- Mettre en œuvre un Calendrier d'entretienDes inspections régulières sont essentielles. Recherchez les premiers signes de rouille sur les brides, tels que des piqûres ou des décolorations. Traitez ces problèmes immédiatement en les nettoyant ou en les réparant. Cela permet d'arrêter la propagation de la rouille sur les brides et de prolonger la durée de vie des brides.

- Veiller à une installation correcte : il est essentiel que le raccordement à la bride soit étanche et bien installé. joint de bride Un mauvais joint permet à l'humidité et aux fluides corrosifs de s'infiltrer, ce qui peut provoquer une rouille importante sur la surface d'étanchéité de la bride.

- Contrôler l'environnement : Dans la mesure du possible, gérer l'environnement autour des brides en utilisant des déshumidificateurs dans les zones à forte humidité. L'isolation peut également empêcher la condensation de se former sur les surfaces des brides. Ces mesures permettent de lutter contre la rouille des brides avant qu'elle ne commence.

Brides que nous proposons

Vous voudrez peut-être aussi lire :

Léger ou puissant. Bride en aluminium ou en titane. Quelle est la meilleure solution pour votre projet ?

Comment choisir une bride ?

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/