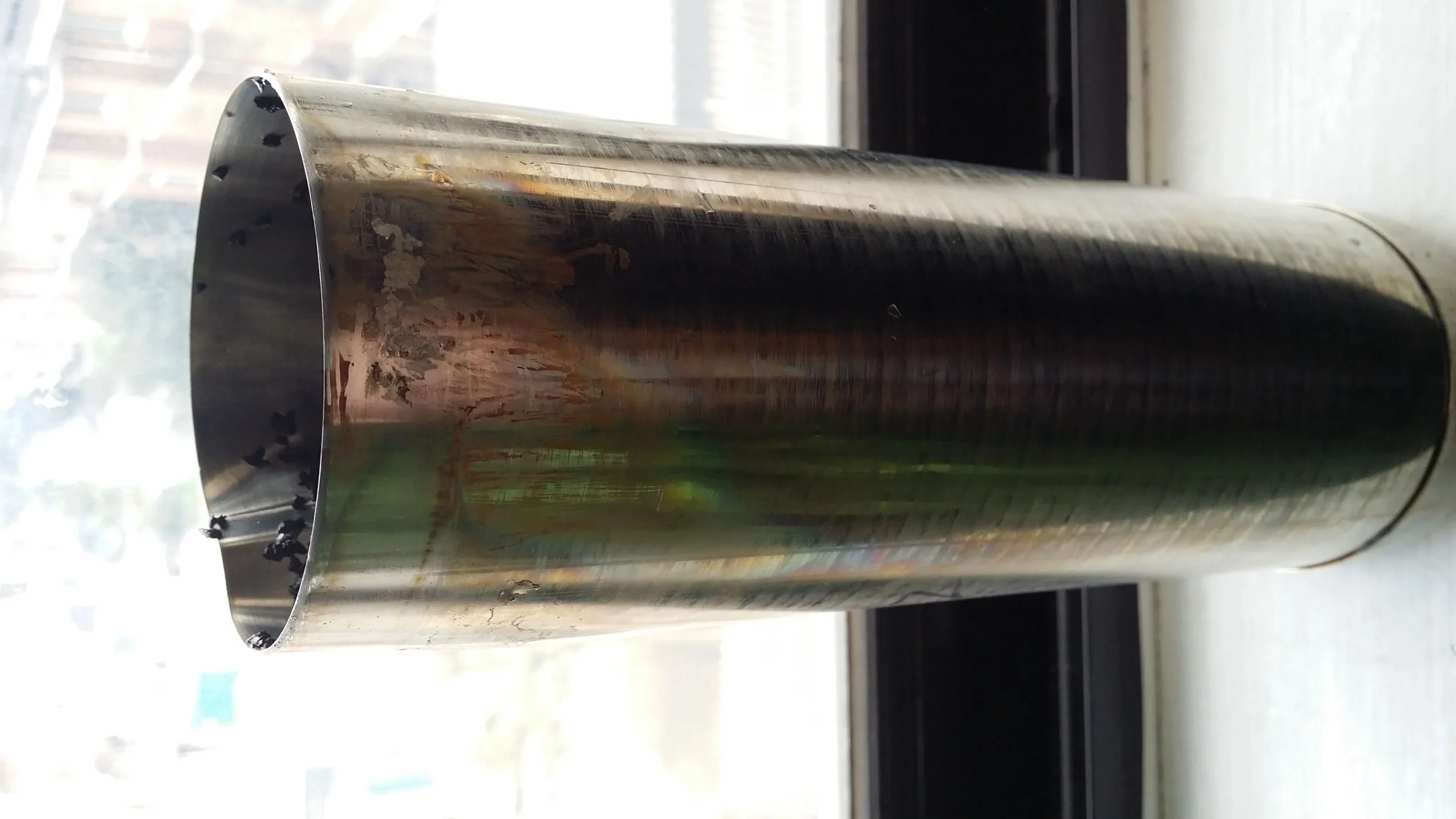

Dans les environnements industriels exigeants, Incoloy 825 Alliage L'importance stratégique de l'UE est démontrée. tuyaux en acier inoxydable et raccords de tuyauterie en acier inoxydable s'avèrent souvent inadéquates dans de telles conditions. L'Incoloy 825 offre une solution exceptionnelle pour les applications sévères. environnements corrosifs.

Qu'est-ce que l'alliage Incoloy 825 ? UNS N08825

L'Incoloy 825 est un alliage nickel-fer-chrome. Il s'agit d'un matériau hautement technique. Sa composition comprend molybdènecuivre et titane. Cette combinaison unique lui confère une puissance incroyable. Il peut résister aux acides oxydants et réducteurs. Sa composition stabilisée lui permet également de résister aux corrosion post-soudure.

Ce que nous faisons

Principaux avantages de l'alliage Incoloy 825 en termes de performances

L'alliage Incoloy 825 est spécialement conçu pour résister à divers environnements chimiques, offrant des performances exceptionnelles dans des conditions d'acide oxydant et réducteur.

La teneur élevée en nickel de l'alliage lui confère une résistance robuste aux chocs. fissuration par corrosion sous contrainteCette caractéristique est particulièrement importante dans les environnements riches en chlore, car elle permet de prévenir efficacement les défaillances catastrophiques sous l'effet du stress.

Une composition stable garantit l'intégrité du matériau post-soudage, en résistant efficacement à la sensibilisation et garantir que les joints soudés conservent une résistance totale à la corrosion.

La présence de molybdène et de chrome permet de résister aux corrosion par piqûres et corrosion par crevassesLa protection de l'intégrité des matériaux dans les zones stagnantes est essentielle pour les raccords de tuyauterie et le matériel d'emballage. brides.

Composition chimique

| Élément | Ni | Cr | Fe | Mo | Cu | Ti | C | Al |

|---|---|---|---|---|---|---|---|---|

| Contenu (wt%) | 38.0 – 46.0 | 19.5 – 23.5 | Équilibre | 2.5 – 3.5 | 1.5 – 3.0 | 0.6 – 1.2 | 0,05 Max | 0.2 Max |

Propriétés mécaniques

| Biens | Résistance à la traction | Limite d'élasticité (décalage de 0,2%) | Élongation | Dureté | Densité |

|---|---|---|---|---|---|

| Valeur (typique) | ≥585MPa(85ksi) | ≥205MPa(30ksi) | ≥30 | ≤210 | 8,14g/cm³ |

Où trouver l'alliage Incoloy 825

- Usines chimiques : Il est utilisé pour manipuler des acides forts. Il résiste à l'ébullition de l'acide sulfurique. Cela prolonge considérablement la durée de vie de l'équipement.

- Contrôle de la pollution : Il est utilisé dans les systèmes de dépollution industrielle. Il résiste aux acides forts présents dans les gaz de combustion.

- Pétrole et gaz : Cet alliage est le matériau de choix pour les gaz acides. Il résiste à la corrosion fissurante sous contrainte. Cette résistance est cruciale pour les équipements de fond de puits.

- Systèmes à haute température : Il conserve ses propriétés à des températures élevées. C'est donc un excellent choix pour les pièces qui chauffent.

- Systèmes de tuyauterie : Pour les raccords de tuyauterie critiques en acier inoxydable, l'Incoloy 825 offre une résistance extrême à la corrosion. Il permet à votre système de fonctionner parfaitement.

Approvisionnement et fabrication de l'alliage Incoloy 825

Demandez toujours un Rapport d'essai des matériaux (MTR). Cela prouve que le matériau est conforme à ce qu'il devrait être.

Travailler avec fournisseurs spécialisés de tubes et raccords en acier inoxydable. Ils connaissent ces aciers alliés et peuvent garantir une fabrication et un contrôle de qualité adéquats. ISO 9001 et CE-PED certifié.

Cet alliage nécessite méthodes de soudage spécifiques. Assurez-vous que votre équipe sait comment s'y prendre.

C'est plus cher au départ. Mais il dure beaucoup plus longtemps. Cela vous permet d'économiser de l'argent à long terme.

Vous voudrez peut-être aussi lire :

Qu'est-ce que l'Inconel 690 / N06690 et pourquoi est-ce important ?

Inconel 601 (2.4851) : Gardien de l'industrie

Alliage de nickel Inconel 718

Inconel vs Incoloy vs Monel

Qu'est-ce que l'Inconel 625 ?

Comment l'Incoloy 925 protège-t-il les systèmes de tuyauterie critiques ?

Qu'est-ce que l'alliage Incoloy 926 ?

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/