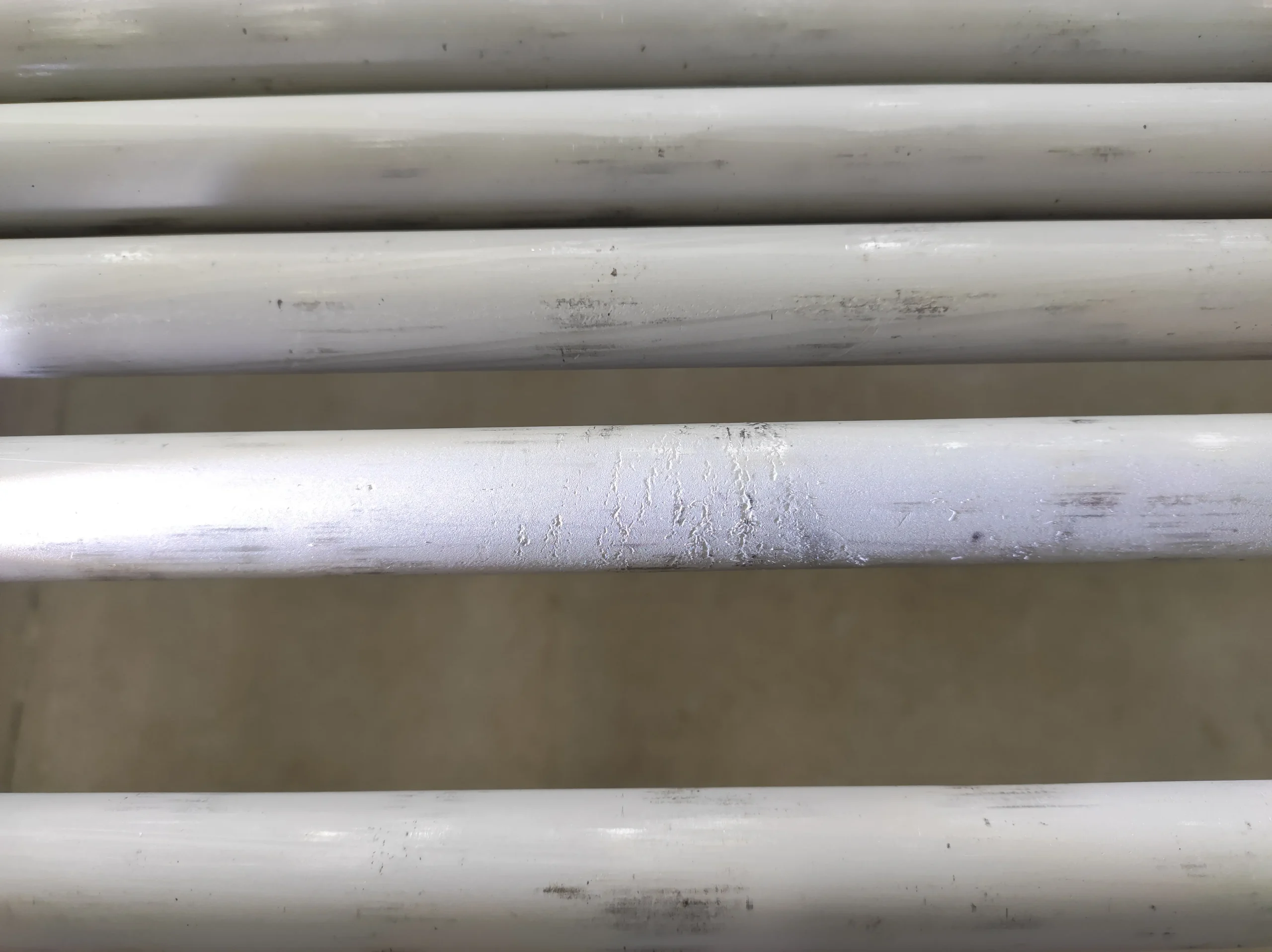

Inconel 690 est un matériau de haute performance connu pour sa résistance à la corrosion. Standard tuyaux en acier inoxydable et raccords de tuyauterie en acier inoxydable n'ont souvent pas la durabilité nécessaire, en particulier dans les environnements corrosifs. C'est là que l'alliage Inconel 690 offre une excellente solution.

Qu'est-ce que l'Inconel 690 | UNS N06690 | GB/T 15059

L'Inconel 690 est un alliage nickel-chrome-fer. Il s'agit d'un matériau renforcé par une solution solide avec une très haute résistance à la corrosion. teneur en chrome (27-31%), ce qui lui confère une excellente résistance à l'usure. Il résiste aux environnements oxydants et réducteurs.

Ce que nous faisons

Principaux atouts de l'Inconel 690

Les alliages Inconel 690 sont résistants à une large gamme de milieux corrosifs, ainsi qu'aux acides oxydants et à l'eau très pure.

Cet alliage conserve sa résistance mécanique à des températures élevées, ce qui lui permet d'offrir des performances fiables et de résister à la corrosion. déformation par fluage.

Sa teneur élevée en nickel empêche fissuration par corrosion sous contrainte et prévient également les fractures soudaines et fragiles.

L'alliage Inconel 690 est facile à mouler et à souder. Cela simplifie le processus de fabrication complexe.

Composition chimique

| Élément | Ni | Cr | Fe | C | Si | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| Contenu (wt%) | Équilibre | 27.0-31.0 | 7.0-11.0 | 0,05 Max | 0.50 Max | 0.50 Max | 0.50 Max | 0.50 Max |

Propriétés mécaniques

| Biens | Résistance à la traction | Limite d'élasticité (décalage de 0,2%) | Élongation | Dureté | Densité | Plage de fusion |

|---|---|---|---|---|---|---|

| Valeur (typique) | ≥520MPa(75.4ksi) | ≥205MPa(29.7ksi) | ≥35 | ≤200 | 8,19g/cm³ | 1340-1375 ℃ |

Inconel 690 dans les systèmes de tuyauterie à haute température

- Nucléaire : L'industrie nucléaire est unique et accorde une grande importance à la sécurité. L'Inconel 690 résiste à la corrosion fissurante sous contrainte et peut être utilisé dans les tuyauteries des générateurs de vapeur pour transporter de l'eau de grande pureté.

- Traitement des déchets : L'inconel 690 peut résister à des environnements très corrosifs et peut être utilisé pour traiter les déchets nucléaires.

- Traitement chimique : Utilisé dans la production d'acide nitrique et de soufre en raison de sa résistance aux acides oxydants.

- Production d'électricité : Échangeurs de chaleur exigent une résistance extrême et doivent pouvoir supporter des cycles thermiques.

- Systèmes de tuyauterie : Les raccords critiques en acier inoxydable nécessitent une résistance extrême à la corrosion, et l'Inconel 690 garantit l'intégrité et la fiabilité des systèmes de tuyauterie.

Articles Similaires:

Tube en acier inoxydable duplex pour le système d'eau de refroidissement des centrales nucléaires

TISCO surmonte à nouveau les difficultés des matériaux en acier inoxydable haut de gamme pour l'énergie nucléaire

Approvisionnement et fabrication de l'Inconel 690

Un complet Rapport d'essai des matériaux (MTR) est nécessaire. Il vérifie la composition précise de l'alliage et garantit ses performances.

Travailler avec fournisseurs spécialisés de tubes et raccords en acier inoxydable. Ils connaissent ces aciers alliés et peuvent garantir une fabrication et un contrôle de qualité adéquats. ISO 9001 et CE-PED certifié.

Il est difficile à usiner et nécessite des outils spéciaux. Des techniques de soudage spécifiques sont indispensables pour garantir l'intégrité de la soudure.

Il est coûteux, il est donc important d'évaluer si le produit a une durée de vie plus longue. Cela peut justifier son coût initial plus élevé.

Vous voudrez peut-être aussi lire :

Inconel 601 (2.4851) : Gardien de l'industrie

Alliage de nickel Inconel 718

Inconel vs Incoloy vs Monel

Qu'est-ce que l'Inconel 625 ?

Alliage 625 VS Alliage 601

Inconel 600 | Spécifications | Applications | Obtenir un devis rapide et gratuit

Qu'est-ce que l'alliage Incoloy 825 ?

Qu'est-ce que l'alliage Incoloy 926 ?

Qu'est-ce que l'alliage Inconel 617 ?

Qu'est-ce que l'Inconel X750 ?

Incoloy 330 - Vue d'ensemble | Introduction | Avantages et inconvénients

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/