Alliage 625 VS Hastelloy C276quelle est la différence ? Ils présentent tous deux une résistance étonnante à la corrosion. Lorsque votre système de tuyauterie nécessite des performances optimales et que l'acier inoxydable standard ne suffit pas, comparez les différences entre les deux pour trouver le meilleur choix. Assurez-vous que votre tuyaux en acier inoxydable et raccords de tuyauterie en acier inoxydable sont construits pour durer.

Qu'est-ce que l'alliage 625 et l'Hastelloy C276 ? Des performances d'élite !

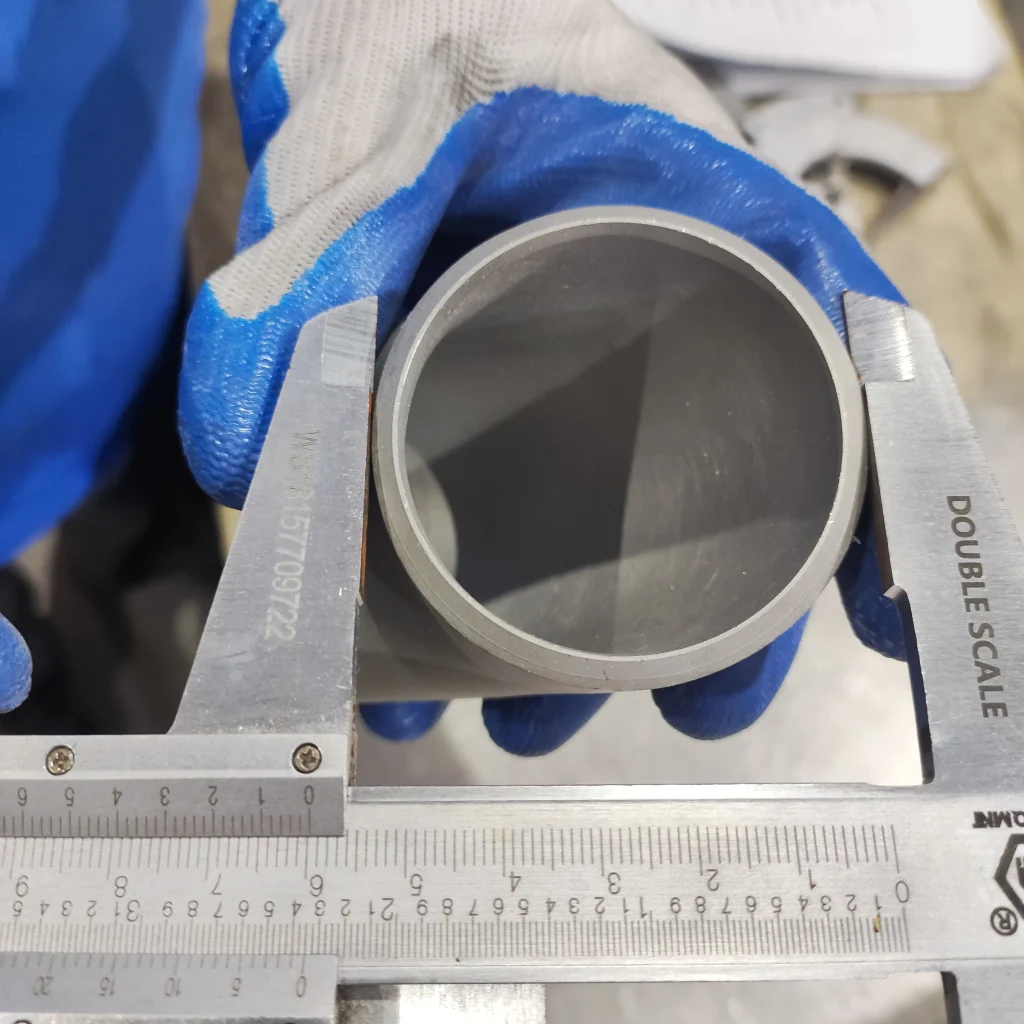

Tube en alliage 625 | N06625 | W.Nr. 2.4856 Tube en alliage de nickel est un alliage de nickel-chrome-molybdène. Il se caractérise par une grande solidité et une large gamme de résistance à la corrosion. Il excelle dans de nombreux milieux agressifs.

Hastelloy C276 (UNS N10276, EN 2.4819) est également un alliage de nickel-chrome-molybdène. Il a une teneur élevée en molybdène et de tungstène, ce qui lui confère une résistance exceptionnelle à la corrosion. Il excelle dans les environnements extrêmement corrosifs.

Ce que nous faisons

Alliage 625 VS Hastelloy C276 : Principaux facteurs de différenciation

L'alliage 625 présente une large gamme de résistance à la corrosion et supporte bien les acides oxydants et réducteurs. L'Hastelloy C276 présente une excellente résistance à la corrosion et donne de bons résultats dans les milieux oxydants et réducteurs agressifs, y compris le chlore humide.

L'alliage 625 a une plus grande résistance et fonctionne bien à partir de basses températures jusqu'à 1000 ℃. L'Hastelloy C276 présente également une excellente résistance à haute température et résiste à la corrosion à des températures extrêmes.

L'Hastelloy C276 a une teneur élevée en molybdène et en tungstène, ce qui augmente considérablement la résistance à la corrosion. piqûre et corrosion par crevasses. Cela donne au C276 un avantage dans les environnements très spécialisés et difficiles.

Tous deux ont une bonne soudabilité. L'Hastelloy C276 est légèrement plus difficile à souder en raison de sa teneur élevée en alliages. Les caractéristiques de l'Hastelloy C276 sont les suivantes procédures de soudage sont essentiels pour les deux. La version à faible teneur en carbone améliore l'intégrité post-soudure.

En général, l'Hastelloy C276 est plus cher en raison de sa composition unique et de son excellente résistance à l'usure.

Désignations globales : Alliage 625 VS Hastelloy C276

| Corps standard | Désignation de l'alliage 625 | Hastelloy C276 Désignation |

|---|---|---|

| UNS | N06625 | N10276 |

| FR | 2.4856 | 2.4819 |

| ASTM/ASME | B443, B444, B474, etc. | B575, B574, B619, etc. |

| ISO | 6208 | 15156-3 |

| GB (Chine) | NS3306 | NS3304 |

Composition chimique clé : Alliage 625 VS Hastelloy C276

| Élément | Ni | Cr | Mo | W | Fe | Nb | C |

|---|---|---|---|---|---|---|---|

| Alliage 625 | ≥58.0 | 20.0-23.0 | 8.0-10.0 | ≤0.35 | ≤5.0 | 3.15-4.15 | ≤0.10 |

| Hastelloy C276 | Équilibre (Min 53.0) | 14.5-16.5 | 15.0-17.0 | 3.0-4.5 | 4.0-7.0 | N/A | ≤0.01 |

Propriétés mécaniques : Alliage 625 VS Hastelloy C276

| Biens | Résistance à la traction | Limite d'élasticité | Élongation | Densité |

|---|---|---|---|---|

| Alliage 625 | ≥827 MPa (120 ksi) | ≥414 MPa (60 ksi) | ≥30% | 8,43g/cm³ |

| Hastelloy C276 | ≥690MPa (100 ksi) | ≥275MPa (40 ksi) | ≥40% | 8,89 g/cm³ |

Applications des tubes et raccords en acier inoxydable

- Alliage 625 : Traitement chimique (acide sulfurique, acide nitrique), aérospatiale (composants de moteurs), marine (composants pour l'eau de mer) et contrôle de la pollution (systèmes de désulfuration des gaz de combustion).

- Hastelloy C276 : Pour une utilisation dans des conditions environnements corrosifs. Cela comprend le chlore gazeux humide, les solutions d'hypochlorite et les mélanges d'acides hautement oxydants. Ils sont couramment utilisés dans les réacteurs pharmaceutiques, le traitement des déchets et le traitement des gaz acides.

- Systèmes de tuyauterie : Ces deux alliages jouent un rôle important dans les systèmes de tuyauterie. tuyaux et raccords en acier inoxydable. Ils traitent les fluides corrosifs et peuvent supporter des pressions et des températures élevées.

Nous sommes un fournisseur expérimenté de tubes et de tuyaux en Hastelloy C276. Fournisseur de tubes Inconel 625 en Chine, Nous sommes spécialisés dans les variantes sans soudure et soudées de cet alliage à haute résistance à la corrosion. Grâce au respect strict des normes de qualité internationales et à la capacité de répondre à des spécifications personnalisées, nous sommes bien équipés pour respecter les délais et les exigences de performance de vos projets, qu'il s'agisse d'applications industrielles critiques ou de projets d'ingénierie spécialisés.

Vous voudrez peut-être aussi lire :

Tableau comparatif des alliages à base de nickel et des qualités de nickel dans diverses régions

Quelle est la différence entre Hastelloy C22 et C276 ?

Maîtriser les produits chimiques agressifs avec Hastelloy C22.

Le résumé le plus complet ! Faites attention à ces neuf points clés concernant le soudage de l'Hastelloy C-276.

Présentation de l'alliage Hastelloy B2

Hastelloy C4 | UNS N06455 Un cheval de bataille stable dans les systèmes de tuyauterie à haute pression

Hastelloy C59 | UNS N06059 Débloquer la résistance ultime

Hastelloy C2000 | Propriétés | Le superalliage de la prochaine génération

Qu'est-ce que l'Hastelloy B3 et comment combat-il les acides forts ?

Qu'est-ce que l'Hastelloy B4 et comment prévient-il la fissuration sous contrainte ?

Qu'est-ce que l'Hastelloy G3 ? Un combattant polyvalent contre la corrosion !

Qu'est-ce que l'Hastelloy G35 et comment résiste-t-il aux acides corrosifs ?

Qu'est-ce que l'Hastelloy G50 et comment l'utiliser pour les tuyauteries critiques ?

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/